- Introduction to Aluminum Alloys

- Composition of 8011 Aluminum Sheet

- Properties of 8011 Aluminum Sheet

- Advantages of 8011 Aluminum Sheet and Plate

- Limitations of 8011 Aluminum Sheet and Plate

- Applications of 8011 Aluminum Sheet and Plate

- Processing of 8011 Aluminum Sheet and Plate

- Maintenance and Care for 8011 Aluminum Sheet and Plate

- Sustainability and Recycling of 8011 Aluminum Sheet

Among the various aluminum sheets, the 8011 aluminum sheet is particularly noteworthy for its suitability in a range of applications.

In this comprehensive guide, we will delve into the 8011 aluminum sheet, specifically focusing on its sheet and plate forms.

We will explore its composition, properties, applications, and processing, ensuring that we provide an in-depth understanding of this alloy.

Introduction to Aluminum Alloys

The meaning of 8011 in 8011 aluminum sheet:

- "8" indicates the major alloying element.

- "0" suggests it is not a modified form of the original alloy.

- "11" specifies the particular alloy.

Composition of 8011 Aluminum Sheet

The 8011 aluminum sheet is part of the 8xxx series, which is known for its excellent corrosion resistance and formability. Its chemical composition plays a crucial role in determining its properties and suitability for various applications. The composition of 8011 aluminum sheet typically includes:

- Aluminum (Al): Aluminum forms the majority of the alloy, usually at over 97% by weight. Its high aluminum content contributes to the alloy's lightweight properties.

- Iron (Fe): Iron is present in small amounts, usually around 0.6% or less. It is considered an impurity in aluminum alloys and can affect their mechanical properties and corrosion resistance.

- Silicon (Si): Silicon is another minor component, generally below 0.7%. It can enhance the alloy's strength and formability.

- Copper (Cu): Copper content in 8011 aluminum alloy is typically kept below 0.1%. A small amount of copper can improve the alloy's resistance to corrosion.

- Manganese (Mn): Manganese is often present at levels under 0.2%. It can act as a deoxidizer and improve the alloy's mechanical properties.

- Magnesium (Mg): Magnesium content in 8011 aluminum is minimal, usually below 0.1%. It enhances the alloy's strength, but this alloy is not primarily chosen for its high-strength properties.

- Zinc (Zn): Zinc is usually found in trace amounts in 8011 aluminum, typically below 0.1%.

- Other Elements: Trace amounts of other elements may be present, depending on the specific manufacturing process and intended use of the alloy.

The specific composition may vary slightly depending on the source and intended application, but these elements form the core composition of 8011 aluminum alloy.

Properties of 8011 Aluminum Sheet

The properties of 8011 aluminum sheet make it highly suitable for numerous applications. Let's examine these properties in detail:

- Lightweight: Like all aluminum sheets, 8011 is lightweight. Its low density (approximately 2.71 g/cm³) makes it an excellent choice for applications where weight reduction is crucial, such as in the automotive and aerospace industries.

- Corrosion Resistance: 8011 aluminum sheet offers exceptional corrosion resistance. This is particularly important for applications where exposure to moisture or aggressive environments is a concern. It can resist the effects of atmospheric corrosion, making it suitable for outdoor applications and the packaging industry.

- Formability: This alloy exhibits good formability, making it easy to shape and manipulate. It can be rolled, extruded, or stamped into various shapes, making it versatile for different manufacturing processes.

- Heat Treatability: While 8011 is not known for its heat-treatable properties, it can still be subjected to work-hardening processes, improving its mechanical properties to some extent.

- Conductivity: Aluminum, including 8011, is an excellent conductor of electricity. This property is valuable in electrical applications.

- Weldability: 8011 aluminum alloy is weldable using various techniques, such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and resistance welding. Its weldability makes it suitable for joining and fabricating components.

- Non-Toxicity: The 8011 alloy is non-toxic, which is a significant advantage in applications where it comes into contact with food or pharmaceuticals, like in the packaging industry.

- Recyclability: Aluminum is highly recyclable, and 8011 is no exception. Recycling aluminum reduces the need for primary aluminum production and contributes to sustainability.

Advantages of 8011 Aluminum Sheet and Plate

The 8011 aluminum sheet offers several advantages that make it a preferred choice for various applications:

- Corrosion Resistance: One of the primary advantages of 8011 aluminum sheet is its exceptional resistance to corrosion, which makes it ideal for use in wet or corrosive environments.

- Formability: The alloy's good formability allows it to be easily shaped and manipulated, making it versatile for manufacturing processes that involve bending, stamping, or drawing.

- Non-Toxicity: Its non-toxic nature is a significant advantage for applications involving food, pharmaceuticals, or anything that requires a clean, safe environment.

- Lightweight: The low density of aluminum contributes to lightweight products, which is particularly important in industries that prioritize weight reduction.

- Recyclability: Aluminum is highly recyclable, making it a sustainable choice. Recycling aluminum consumes significantly less energy compared to producing it from raw materials.

- Electrical Conductivity: Its good electrical conductivity is beneficial in applications requiring electrical or thermal conductivity.

- Low Maintenance: Due to its corrosion resistance, 8011 aluminum sheet requires minimal maintenance over its service life.

- Aesthetic Appeal: The alloy's natural appearance and ability to accept various surface finishes make it suitable for decorative applications.

Limitations of 8011 Aluminum Sheet and Plate

While 8011 aluminum sheet offers numerous advantages, it also has some limitations that should be considered when selecting it for a particular application:

- Not Heat-Treatable: 8011 is not a heat-treatable alloy, which means it cannot be significantly strengthened through heat treatment. Its strength is mainly achieved through cold working and strain hardening.

- Moderate Strength: While it offers sufficient strength for many applications, it may not be the best choice for applications requiring high strength.

- Higher Cost: Aluminum, in general, tends to be more expensive than some other materials, which can impact the cost of products made from 8011 alloy.

- Limited High-Temperature Applications: Aluminum alloys have lower melting points and are less suitable for high-temperature applications compared to materials like steel or titanium.

- Surface Vulnerability: The natural oxide layer on aluminum can be damaged, leading to localized corrosion in aggressive environments. Proper surface treatment is essential to prevent this.

- Fatigue Limit: Aluminum alloys have a finite fatigue limit, meaning they are susceptible to fatigue failure over time, especially under cyclic loading conditions.

Applications of 8011 Aluminum Sheet and Plate

The 8011 aluminum alloy's unique combination of properties makes it suitable for various applications across different industries. Let's explore some of its primary uses:

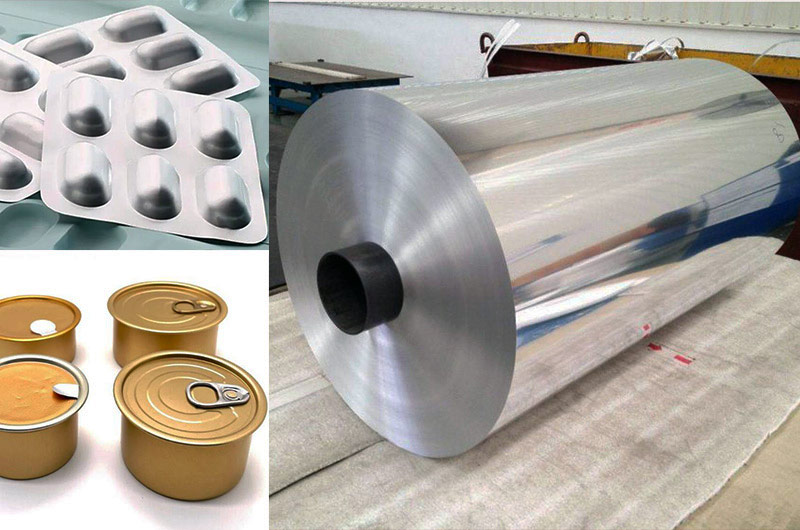

1. 8011 Aluminum Sheet Coil for Packaging

8011 Aluminum Sheet Coil is commonly used in the packaging industry for containers, foils, and lids. Its non-toxic nature, corrosion resistance, and malleability make it an ideal choice for packaging food, pharmaceuticals, and other sensitive products.

2. 8011 Aluminum Sheet Coil for Pharmaceutical Packaging

The alloy's high purity and non-toxicity make it well-suited for pharmaceutical packaging, where product safety is paramount. It is often used to create blister packs and medicine bottle caps.

3. 8011 Aluminum Sheet Coil for Food Packaging

The corrosion-resistant properties of 8011 aluminum are critical for food packaging applications. It is used for making food containers, trays, and foils.

4. 8011 Aluminum Sheet Coil for Cookware

Some cookware and kitchen utensils are made from 8011 aluminum, benefiting from its formability and corrosion resistance.

5. Electrical Conductors

Due to its good electrical conductivity, 8011 aluminum is used in electrical applications, including busbars, conductive wires, and transformers.

6. Building and Construction

In the construction industry, 8011 aluminum finds application in roofing, cladding, and architectural elements due to its corrosion resistance and formability.

7. Heat Exchangers

This alloy is used in the production of heat exchangers, which are essential components in HVAC systems, radiators, and air conditioning units.

8. Automotive Components

While not as common in structural components, 8011 aluminum may be used for various automotive parts where corrosion resistance and lightweight properties are essential.

9. Aerospace

In the aerospace industry, 8011 aluminum can be found in non-critical components, such as interior paneling and trim, due to its lightweight and corrosion-resistant properties.

10. General Sheet and Plate Applications

Beyond specific industries, 8011 aluminum sheets and plates are used for a variety of general applications, from signage to decorative elements, where corrosion resistance and formability are advantageous.

Processing of 8011 Aluminum Sheet and Plate

The processing of 8011 aluminum sheets and plates involves several key steps to convert the raw material into finished products suitable for various applications. These steps include:

- Alloying and Melting: The production process begins with alloying aluminum with the specified elements, including trace impurities. The alloy is then melted in a furnace, typically using the direct chill casting method to create cast ingots.

- Hot Rolling: After casting, the ingots are hot-rolled into intermediate products called hot-rolled coils or sheets. The hot rolling process reduces the thickness and increases the length of the material. It also refines the microstructure of the alloy.

- Cold Rolling: Hot-rolled coils are further processed through cold rolling to achieve the desired thickness and surface finish. Cold rolling enhances the material's mechanical properties and dimensional accuracy.

- Annealing: Annealing is a heat treatment process used to relieve internal stresses and improve the alloy's ductility. It is especially important for applications that require extensive forming, such as packaging materials.

- Cutting and Slitting: The rolled and annealed material is then cut into specific sizes or slit into narrower strips, depending on the intended application.

- Surface Treatment: Depending on the application, the surfaces of the sheets and plates may be treated to improve their appearance or corrosion resistance. Treatments can include anodizing, painting, or coatings.

- Quality Control: Throughout the processing, quality control measures are implemented to ensure that the final product meets the required specifications in terms of thickness, mechanical properties, and surface finish.

Maintenance and Care for 8011 Aluminum Sheet and Plate

Proper maintenance and care are essential to ensure the longevity and performance of products made from 8011 aluminum sheet and plate. Here are some key considerations:

- Cleaning: Regularly clean the surface of 8011 aluminum sheets to remove dirt, dust, and contaminants. Mild detergent solutions and soft cloths or sponges are suitable for this purpose. Avoid abrasive materials that can scratch the surface.

- Avoid Abrasion: Take care to prevent abrasion and scratching of the aluminum surface, as this can compromise its corrosion resistance and appearance.

- Surface Treatment: Depending on the application, consider applying appropriate surface treatments, such as anodizing or painting, to enhance corrosion resistance and appearance.

- Avoid High Temperatures: Avoid exposing 8011 aluminum products to high temperatures, as it has lower heat resistance compared to other materials like stainless steel.

- Inspect for Damage: Regularly inspect products for any signs of damage, including cracks, dents, or corrosion. Address any issues promptly to prevent further deterioration.

- Keep Dry: If used in outdoor applications, ensure that the aluminum products remain dry and well-ventilated. Moisture can lead to localized corrosion.

Sustainability and Recycling of 8011 Aluminum Sheet

Aluminum is a highly sustainable material due to its recyclability and energy-efficient production. The 8011 aluminum sheet, like all aluminum sheets, can be recycled without a significant loss of quality.