- Typical Mechanical Properties of 7075 Aluminum Plate

- 7075 Aluminum Plate Specifications

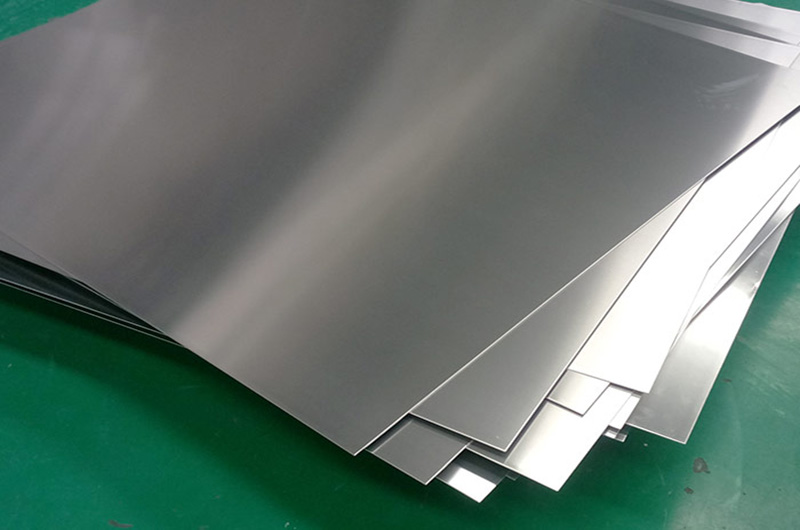

- Surface Quality of 7075 Aluminum Plate

- 7075 Aluminum Plate Thickness Tolerances

- 7075 Aluminum Plate Applications

- 7075 Aluminum Plate for Sale

- Chemical Composition of 7075 Aluminum Plate

- How to Choose the Hot-selling 7075 Aluminum Plate

- 7075 Aluminum Plate Supplier

7075 alloy is the most typical aerospace super duralumin, used to manufacture various structural parts, especially aerospace structural parts, and is the most widely used high-strength aluminum alloy today.

7075 aluminum plate is a high-strength aluminum alloy plate, which is usually used in aviation, aerospace, national defense and other fields. Such as middle fuselage sheet bending and long truss, keel beam web, middle and rear fuselage long truss, passenger observation window frame forgings, cargo cabin door frame, nose front pressure frame edge, cabin door frame, etc.

Typical Mechanical Properties of 7075 Aluminum Plate

7075 aluminum plate is a high-strength aluminum alloy plate with excellent mechanical properties. The mechanical properties of 7075 aluminum plate depend on various factors, such as the temper, thickness, and heat treatment condition. Generally, the mechanical properties of 7075 aluminum plate are as follows :

| Temper | Tensile Strength(KSI) | Yield Strength(KSI) | Elongation(%) |

| O (annealed) | 40 | 21 | 9-10 |

| T6 | 74-78 | 63-69 | 5-8 |

These values may vary depending on the specific product specifications and testing methods. In addition, the mechanical properties of 7075 aluminum plate can be further improved by using suitable heat treatment processes, such as annealing, solution treatment, quenching, and aging.

7075 Aluminum Plate Specifications

7075 aluminum sheet can be produced into sheets of various sizes and thicknesses according to different application needs and processing requirements. Generally speaking, the size and thickness of 7075 aluminum sheet can be selected within the following ranges :

- Thickness : 0.2mm-600mm

- Width : ≤2600mm

- Length : ≤16000mm

- Standards : AMS 4044, AMS 4045, AMS 4046, AMS 4078, AMS 4122, AMS 4123, EN 4, ASTM B209, AMS-QQ-A-250, etc.

Of course, the specific size and thickness range also depends on different production equipment and processing technology. It is necessary to select the appropriate size and thickness of 7075 aluminum plate according to actual needs to meet the requirements of engineering or product use.

Surface Quality of 7075 Aluminum Plate

The surface quality of 7075 aluminum plate will be strictly controlled and tested for the appearance, corrosion resistance and mechanical properties of the product.

- Surface smoothness : The surface of 7075 aluminum plate is smooth, without ripples and unevenness.

- No obvious defects on the surface : There are no obvious defects such as bubbles, cracks, scratches, oxidation and color difference on the surface of the 7075 aluminum plate.

- Surface cleanliness : The surface of the 7075 aluminum plate is clean and free of stains, and the surface oxides are removed at the same time.

In order to ensure the surface quality of the 7075 aluminum plate, Haomei Aluminum takes corresponding measures during the processing :

- Polish the surface of the aluminum plate and clean it with cleaning agent.

- During transportation and use, protect the surface of the 7075 aluminum plate to avoid scratches or damage.

- If the customer needs to further improve the surface quality of the 7075 aluminum plate, surface treatment methods such as anodic oxidation can be carried out.

7075 Aluminum Plate Thickness Tolerances

The thickness tolerance of 7075 aluminum plate should be determined according to the thickness grade of aluminum plate.

It should be noted that the tolerance range here is only for reference, and the specific thickness tolerance may also vary according to different specifications and requirements. When purchasing 7075 aluminum sheets, you need to know the specific thickness tolerance standards to ensure that the quality of the aluminum sheets meets the requirements.

| Mechanical Property | Value |

|---|---|

| Thickness | The Tolerance Range |

| >6.3mm | ±0.15mm |

| 1.5mm - 6.3mm | ±0.10mm |

| <1.5mm | ±0.05mm |

7075 Aluminum Plate Applications

7075 aluminum plate has excellent mechanical properties, corrosion resistance, strength and toughness, so it is widely used in aerospace, automobiles, trains, ships, molds, equipment manufacturing, electronic products and other fields.

The following are some typical applications of 7075 aluminum sheet :

- Aerospace : 7075 aluminum plate is widely used in the fuselage structure, propeller, engine and other components in the aerospace field because of its high strength, light weight, and fatigue resistance.

- Automobile : 7075 aluminum sheet is also widely used in automobile manufacturing, such as for automobile chassis, wheels, body structure, etc., which can effectively improve the safety of automobiles, reduce body weight and fuel consumption.

- Ships : 7075 aluminum sheets are often used in the manufacture of ship structures and equipment, such as hulls, decks, propellers, etc., due to their good corrosion resistance and durability.

- Mold : 7075 aluminum plate has good processing performance and high hardness, and is suitable for making various molds, such as plastic molds, die-casting molds, etc.

- Electronic products : 7075 aluminum sheet is often used to manufacture electronic product casings, radiators, etc. due to its good electrical conductivity and thermal conductivity.

In addition to the above fields, 7075 aluminum sheet is also widely used in the manufacture of sports equipment, stage equipment, military equipment and other fields.

7075 Aluminum Plate for Sale

7075 t6 Aluminum Plate

7075-T6 aluminum plate is a 7075 aluminum alloy plate, and T6 means that it has undergone dissolution treatment and natural aging.

7076-7075 t6 aluminum plate has relatively low strength, but has better toughness and ductility.

7075 t6 aluminum plate is suitable for applications requiring high toughness and ductility, such as aerospace, automotive manufacturing, etc.

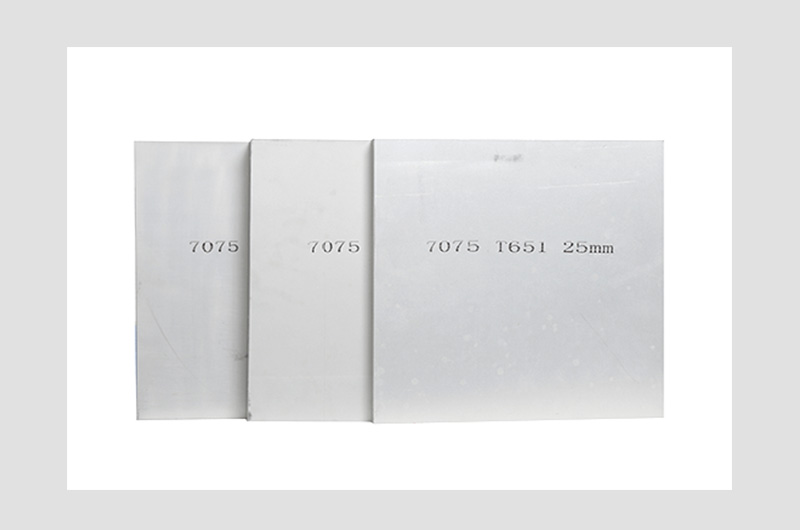

7075 t651 Aluminum Plate

The 7075-T651 aluminum plate is the same as the 7075 aluminum alloy plate, while T651 means that it has undergone dissolution treatment and tensile balance treatment.

7075 T651 aluminum plate has been treated with tensile balance, which has high strength but relatively poor toughness.

7075 t6 51 aluminum plate is suitable for applications requiring higher strength and rigidity, such as aero engine parts, high-speed train body, etc.

7075-t7351 Aluminum Plate

The treatment process of 7075-T7351 aluminum plate includes dissolution treatment, water quenching treatment and stabilization treatment.

The main features of 7075-t7351 aluminum plate are high hardness, high strength, good corrosion resistance and machinability.

7075-t7351 aluminum plate is widely used in aircraft fuselage, wing plate, propeller, missile parts, high-speed train body, automobile engine, etc.

7075-t7451 Aluminum Plate

The treatment process of 7075-T7451 aluminum plate includes dissolution treatment, stabilization treatment and natural aging treatment.

The main features of 7075-t7451 aluminum plate are high hardness, high strength, good corrosion resistance and good toughness.

The application of 7075-t7451 aluminum plate is roughly the same as that of 7075 t7351 aluminum plate, such as aircraft fuselage, wing plate, propeller, missile parts, high-speed train body, automobile engine, etc.

Chemical Composition of 7075 Aluminum Plate

| Mechanical Property | Value |

|---|---|

| Aluminum (Al) | 90.40% |

| Zinc (Zn) | 5.30% |

| Magnesium (Mg) | 2.50% |

| Copper (Cu) | 1.60% |

| Chromium (Cr) | 0.23% |

| Manganese (Mn) | 0.15% |

| Titanium (Ti) | 0.15% |

| Silicon (Si) | 0.10% |

| Iron (Fe) | 0.05% |

| Other elements |

0.15% |

How to Choose the Hot-selling 7075 Aluminum Plate

Among the 7075 aluminum plates, 7075-T7351, 7075-T7451, 7075-T6 and 7075-T651 are all products that are more frequently consulted by customers.

In contrast,

Both 7075 T7451 aluminum plate and 7075-T7351 aluminum plate have been stabilized and have higher hardness and strength than 7075-T651 aluminum plate and 7075-T6 aluminum plate.

The 7075 T7451 aluminum plate has undergone natural aging treatment after the stabilization treatment, which has better toughness and a certain degree of plasticity than the 7075-T7351 aluminum plate.

When choosing which heat treatment state 7075 aluminum plate to use, you need to choose according to the specific application scenario and requirements :

- If you need high strength and high hardness, you can choose 7075-T7351 or 7075-T7451 aluminum plate.

- If you need better toughness and plasticity, you can choose 7075-T7451 aluminum plate.

- The aluminum plate in the T651 state has been subjected to tensile balance treatment, and has high strength, but relatively poor toughness.

- The aluminum plate in the T6 state has undergone natural aging treatment, and its strength is relatively low, but it has better toughness and ductility.

7075 Aluminum Plate Supplier

Haomei Aluminum has ISO certification, quality certification and other relevant qualifications, which can ensure that the quality and performance of products meet national and industry standards. We provide advanced production equipment and richer production experience, which can better meet the needs of customers and provide good after-sales service.