- Typical Mechanical Properties of 7005 Aluminum Plate

- 7005 Aluminum Plate Surface Treatment

- 7005 Aluminum Plate Welding

- Equivalents of AA 7005

- Typical 7005 Aluminum Plate

- 7005 Aluminum Plate Thermal Properties

- 7005 Aluminum Plate Process Properties

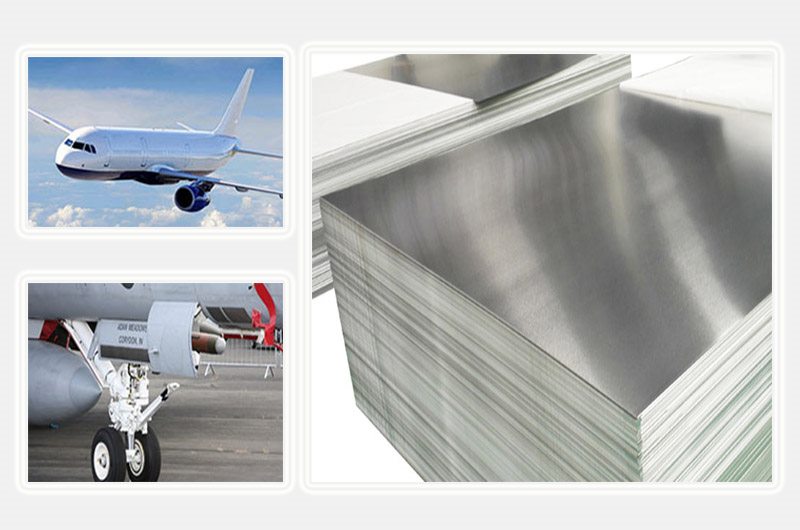

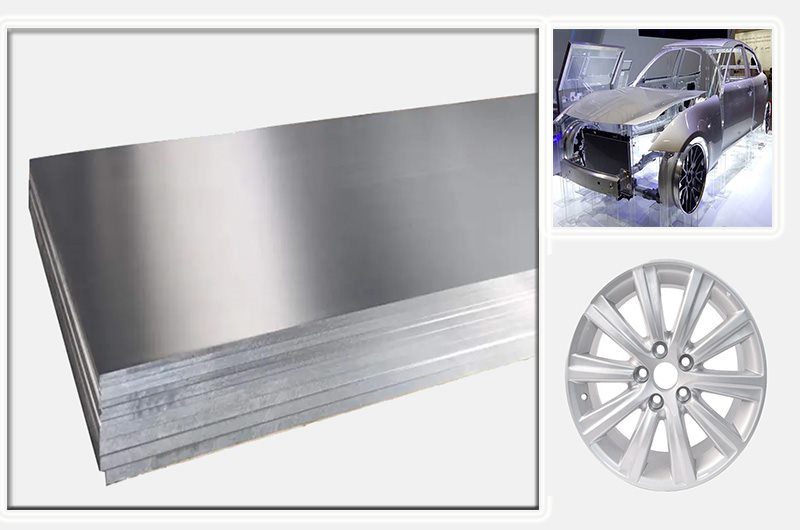

- 7005 Aluminum Plate Applications

- Chemical Composition of 7005 Aluminum Plate

7005 aluminum plate is a high-strength aluminum alloy with zinc as the main alloying element. It is commonly used in applications requiring high strength, low weight and excellent corrosion resistance.

- High Strength-to-Weight Ratio : Has a high strength-to-weight ratio, making it the material of choice in industries such as aerospace, automotive and sporting goods where weight reduction is critical.

- Excellent corrosion resistance : 7005 aluminum plate has excellent corrosion resistance, especially in harsh environments. This property makes it ideal for marine and offshore applications.

- Good weldability : With good weldability, complex shapes and structures can be formed by welding.

- Accurate dimensional stability : Accurate dimensional stability can be achieved through machining, which is especially important in industries with high precision requirements such as aerospace and automobiles.

- High formability : 7005 aluminum plate has high formability and can manufacture parts with complex shapes and designs.

Typical Mechanical Properties of 7005 Aluminum Plate

| Physical Performance Indicators | Tensile Strength (MPa) | Yield Strength (Mpa) | Elongation (%) |

| 7005 - O | 195 | 80 | 20 |

| 7005 - T6 | 350 | 290 | 13 |

7005 Aluminum Plate Surface Treatment

- Mill Finish

- Polished

- Close Tolerance

- Polished Blocks

- Anodized

7005 Aluminum Plate Welding

7005 has excellent weldability under all standard methods, including GMAW (MIG) and GTAW (TIG). Filler alloy 4043 is the main filler material, but 5356 welding wire is recommended as an alternative.

The most typical characteristic is weldability. There are many other aluminum alloys, such as 7075 and 2014, which are stronger than 6061 and 7005, but are almost impossible to weld.

Equivalents of AA 7005

UNS A97005, Aluminium 7005, AA7005, Al7005

Typical 7005 Aluminum Plate

7005 T6 Aluminum Plate

T6 is the most commonly used state of 7005 aluminum plate, and the T6 state provides the highest strength and hardness for the material.

- Features : high strength, hardness and rigidity.

- Best for application areas : aerospace and automotive industries.

- Specific application examples : aircraft wing and fuselage sections, bicycle frames, automotive wheels and suspension components.

7005 T651 Aluminum Plate

T651 This temper is similar to T6, but with additional stretch added to improve the dimensional stability of the material.

- Features : high strength, stiffness and dimensional stability.

- Best for application areas : aerospace and automotive industries.

- Specific application examples : aircraft wing and fuselage parts, automotive engine parts.

7005 T4 Aluminum Plate

T4 This temper provides good formability and is used for parts requiring complex shapes or complex designs.

- Features : good formability.

- Best for applications : the automotive industry.

- Specific application examples : automotive body panels, heat exchanger fins.

7005 O Aluminum Plate

O This is the softest state of 7005 aluminum sheet and offers the highest level of formability.

- Properties : soft and highly malleable.

- Best for application : sheet metal processing industry.

- Specific application examples : deep-drawn parts, cans and containers.

7005 T73 Aluminum Plate

T73 This temper provides high strength and resistance to stress corrosion cracking.

- Features : high strength, resistance to stress corrosion cracking.

- Most suitable field of application : marine and offshore industry.

- Specific application examples : ship components, offshore drilling platforms.

7005 Aluminum Plate Thermal Properties

| Thermal Properties | Metric | English |

| CTE, linear | 21.4 µm/m-°C | 11.9 µin/in-°F |

| @Temperature -50.0 - 20.0 °C | @Temperature -58.0 - 68.0 °F | |

| 23.1 µm/m-°C | 12.8 µin/in-°F | |

| @Temperature 20.0 - 100 °C | @Temperature 68.0 - 212 °F | |

| 23.6 µm/m-°C | 13.1 µin/in-°F | |

| @Temperature 20.0 - 100 °C | @Temperature 68.0 - 212 °F | |

| 24.0 µm/m-°C | 13.3 µin/in-°F | |

| @Temperature 20.0 - 200 °C | @Temperature 68.0 - 392 °F | |

| 25.0 µm/m-°C | 13.9 µin/in-°F | |

| @Temperature 20.0 - 300 °C | @Temperature 68.0 - 572 °F | |

| Specific Heat Capacity | 0.875 J/g-°C | 0.209 BTU/lb-°F |

| Thermal Conductivity | 137 W/m-K | 951 BTU-in/hr-ft²-°F |

| Melting Point | 607 - 643 °C | 1120 - 1190 °F |

| Solidus | 607 °C | 1120 °F |

| Liquidus | 643 °C | 1190 °F |

7005 Aluminum Plate Process Properties

| Processing Properties | Metric | English | Processing Properties |

| Annealing Temperature | 343 °C | 650 °F | Annealing Temperature |

| Solution Temperature | 399 °C | 750 °F | Solution Temperature |

7005 Aluminum Plate Applications

7005 Aerospace Aluminum Plate

7005 aluminum plate is used in the construction of aircraft and spacecraft components due to its high strength-to-weight ratio and good corrosion resistance.

- Condition : T6, The T6 condition provides the material with the highest strength and hardness, making it suitable for high stress applications such as aircraft structural components.

- Advantages : high strength to weight ratio, good fatigue resistance, corrosion resistance in harsh environments, etc.

- Applications : Used in the manufacture of aircraft structural components such as wing and fuselage sections, engine components and landing gear.

Click to learn more aboutAerospace Aluminum Plate

7005 Aluminum for Bicycle Frame

7005 aluminum plate is a popular choice for performance bicycle frames due to its strength, stiffness and lightweight properties.

- Condition : T6 or T651 conditions, T6 or T651 conditions provide good strength, stiffness and fatigue resistance, making them ideal for high-performance bicycle frames.

- Advantages : Including light weight, stiffness and durability.

7005 Aluminum for Sports Equipment

7005 aluminum plate is commonly used in the construction of sporting goods such as tennis rackets, baseball bats, and hockey sticks.

- Condition : T6, The T6 condition provides good strength and stiffness, making it suitable for sports equipment that requires high performance and durability.

- Advantages : including high strength, durability and corrosion resistance.

7005 Automotive Aluminum Plate

7005 aluminum plate is used to make auto parts due to its strength and corrosion resistance.

-

State :

- The T6 or T651 temper is typically used for automotive parts requiring high strength and stiffness,

- T4 is used for parts requiring good formability.

- Advantages : include high strength-to-weight ratio, good corrosion resistance and ease of fabrication.

- Applications : eg wheels, suspension components and body panels.

Click to learn more aboutAutomotive Aluminum Plate

7005 Marine Aluminum Plate

7005 aluminum plate is used in the construction of marine equipment such as marine equipment because of its resistance to salt water corrosion.

- Condition : T6, The T6 condition provides good strength and corrosion resistance making it suitable for use in saltwater environments.

- Advantages : Including corrosion resistance, durability and light weight.

Click to learn more aboutMarine Grage Aluminum Plate

Industrial Application

7005 aluminum plate is used in the construction of industrial machinery due to its high strength and wear resistance.

-

State :

- The T6 or T651 temper is typically used for automotive parts requiring high strength and stiffness,

- T4 is used for parts requiring good formability.

- Advantages : include high strength-to-weight ratio, wear resistance and ease of fabrication.

- Application : 7005 aluminum plate is used in the manufacture of industrial machinery components such as frames, housings and machine guards.

Chemical Composition of 7005 Aluminum Plate

| Element | Composition % |

| Si | 0.35 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.20 - 0.70 |

| Mg | 1.0 - 1.8 |

| Cr | 0.06 - 0.20 |

| Ni | - |

| Zn | 4.0 - 5.0 |

| Ti | 0.01 - 0.06 |

| Zr | 0.08 - 0.20 |

| Al | Remainder |