- Basic Introduction to 6061 Aluminum Discs

- Advantages of 6061 Aluminum Discs

- Characteristics of 6061 Aluminum Discs

- Chemical and Physical Properties

- 6061 Aluminum Discs Surface Treatment

- 6061 Aluminum Disc Circle Applications

- The 6000 Series Aluminum Discs

- When to Choose 6061 Aluminum Discs

- 6061 Aluminum Discs Production and Processing Precautions

Aluminum is a versatile and widely used material in various industries, thanks to its excellent combination of properties such as lightweight, corrosion resistance, and high strength. Among the many aluminum alloys available, the 6061 aluminum alloy stands out as a popular choice due to its remarkable attributes.

6061 aluminum disc is an aluminum-silicon-magnesium alloy that is strengthened by precipitation hardening. The alloy offers moderate strength, formability, weldability, machinability and corrosion resistance.

Basic Introduction to 6061 Aluminum Discs

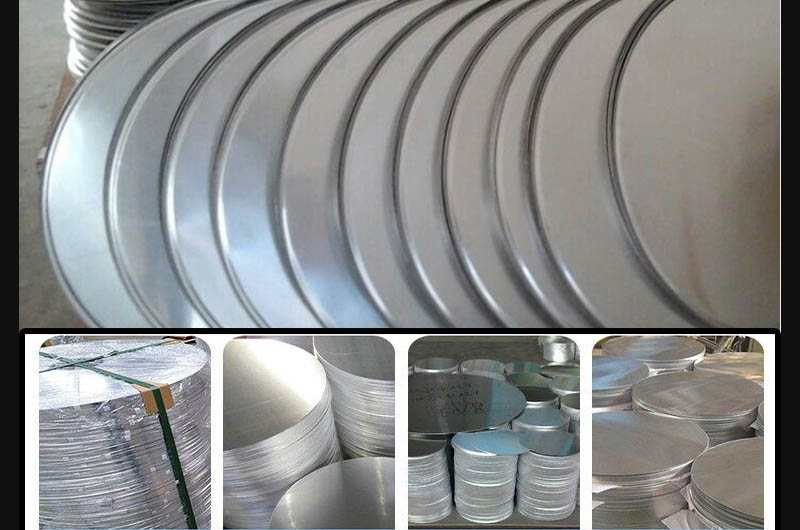

6061 aluminum discs are circular pieces of aluminum alloy made from the 6000 Series Aluminum alloy. This series, which includes 6061, is known for its excellent combination of strength, machinability, and corrosion resistance. 6061 aluminum is primarily composed of aluminum, magnesium, and silicon, with small amounts of copper and other trace elements. The alloy is highly regarded for its mechanical properties and is often chosen for structural applications.

Advantages of 6061 Aluminum Discs

- 1. Heat treatment strengthening, high impact toughness.

- 2. Excellent thermoplasticity, welding performance and corrosion resistance.

- 3. It does not deform after processing, the surface is very smooth, and it is easy to anodize and color.

- 4. Excellent interface characteristics, high strength, good usability and strong corrosion resistance.

Characteristics of 6061 Aluminum Discs

| Characteristic | Value |

|---|---|

| Alloy Number | 6061 |

| Equivalent alloy name | a6061 aluminum, 6061a, aa6061, 6061aa, al6061 |

| Temper | O, T4, T5, T6, T651, T650, T651, T851 etc |

| Diameter | 50mm to 1000mm |

| Thickness | 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm etc |

| Characteristics | Heat treatable alloy with excellent strength. |

Chemical and Physical Properties

6061 Aluminum Discs Chemical Composition

The chemical composition of 6061 aluminum discs is as follows:

- Aluminum (Al): 97.9%

- Magnesium (Mg): 1.0%

- Silicon (Si): 0.6%

- Copper (Cu): 0.28%

- Iron (Fe): 0.25%

- Others (each): 0.15%

- Others (total): 0.15%

These elements work in harmony to create an aluminum alloy with exceptional properties.

Physical Properties of 6061 Aluminum Disc Circle

6061 aluminum discs exhibit the following physical properties:

- Density: 2.7 g/cm³

- Melting Point: 582-652°C (1, 080-1, 205°F)

- Young's Modulus: 69 GPa (10, 000, 000 psi)

- Thermal Conductivity: 166 W/m·K

- Electrical Conductivity: 43-47% IACS (International Annealed Copper Standard)

These physical properties make 6061 aluminum discs well-suited for a wide range of applications, as they offer a balance of strength, malleability, and other essential characteristics.

6061 Aluminum Discs Surface Treatment

To enhance the corrosion resistance and appearance of 6061 aluminum discs, various surface treatments can be applied:

1. 6061 Anodized Aluminum Disc Circle

Anodizing is a common surface treatment for aluminum alloys. It forms a protective oxide layer on the surface, which improves corrosion resistance and provides a base for coloring. This process is widely used for decorative and architectural applications.

2. 6061 Powder Coated Aluminum Disc Circle

Powder coating involves applying a dry powder to the surface of the aluminum disc and then curing it through heat. This creates a durable and attractive finish with various color options.

3. 6061 Polished Aluminum Disc Circle

Polishing the aluminum disc can provide a high-gloss finish, making it suitable for decorative and aesthetic applications.

4. 6061 Brushed Aluminum Disc Circle

Brushed finishes are created by mechanically brushing the surface, resulting in a textured appearance. This is often used in architectural and industrial design.

Surface treatment choices depend on the application and desired aesthetic, as well as the specific requirements for corrosion resistance.

6061 Aluminum Disc Circle Applications

6061 aluminum discs find application in a wide range of industries due to their favorable properties:

1. 6061 Aluminum Disc for Aerospace

6061 aluminum discs are used in aircraft components, including wings, fuselages, and structural elements, thanks to their high strength-to-weight ratio.

2. 6061 Aluminum Disc for Automotive

In the automotive industry, these discs are employed for various components such as wheels, suspension parts, and structural elements due to their lightweight and durable nature.

3. 6061 Aluminum Disc for Marine

The corrosion resistance of 6061 aluminum makes it an ideal choice for marine applications, including boat hulls, masts, and other components.

4. 6061 Aluminum Disc for Architecture and Construction

6061 aluminum discs are commonly used in architectural applications such as curtain walls, structural framing, and decorative elements due to their excellent strength and corrosion resistance.

5. 6061 Aluminum Disc for Sports and Recreation

Bicycles, camping gear, and sports equipment often incorporate 6061 aluminum discs because of their lightweight and durable properties.

6. 6061 Aluminum Disc for Electronics

Electronic enclosures and heat sinks benefit from the excellent thermal conductivity of 6061 aluminum.

The 6000 Series Aluminum Discs

6061 aluminum discs are part of the broader 6000 Series Aluminum discs family, which includes various alloys such as 6063, 6082, and 6005.

These alloys share the 6000 series designation due to their alloying elements, primarily magnesium and silicon. Each alloy within this series has unique properties and applications.

6063 Aluminum Disc Circle

Known for its excellent extrudability, 6063 aluminum is often used in architectural applications and for making extruded shapes like window frames and profiles.

6082 Aluminum Disc Circle

Offering high tensile strength and excellent corrosion resistance, 6082 aluminum is favored for structural applications in the automotive and marine industries.

6005 Aluminum Disc Circle

6005 aluminum offers good formability and corrosion resistance, making it suitable for various applications, including architectural components and profiles.

The 6000 Series Aluminum discs are versatile and widely used, and the choice of which alloy to use depends on the specific requirements of the application.

When to Choose 6061 Aluminum Discs

Choosing 6061 aluminum discs is a wise decision when specific properties are required, including:

High Strength: 6061 aluminum discs are known for their excellent strength, making them a suitable choice for structural and load-bearing components.

Corrosion Resistance: Their resistance to corrosion, particularly in marine environments, makes 6061 discs a preferred choice for applications exposed to moisture.

Machinability: The ease with which 6061 aluminum can be machined makes it an ideal choice for applications requiring complex shapes or precise tolerances.

Weldability: 6061 aluminum can be successfully welded, making it suitable for applications where joints or connections are necessary.

Heat Treatment: When heat treatment is required to enhance mechanical properties, 6061 aluminum allows for this process.

6061 Aluminum Discs Production and Processing Precautions

Producing high-quality 6061 aluminum discs requires adherence to specific precautions:

1. Alloy Composition Control

Controlling the composition of the alloy is crucial to maintain consistent properties. Any deviation in the content of alloying elements, particularly magnesium and silicon, can affect the final product's mechanical and chemical properties.

2. Heat Treatment

6061 aluminum discs can be heat-treated to enhance their strength and hardness. Heat treatment processes like solution heat treatment and precipitation hardening are often employed.

Precise control of temperatures and times is essential to ensure the desired material properties are achieved.

3. Machining

6061 aluminum discs are renowned for their machinability. However, proper tool selection, lubrication, and cutting parameters are essential to avoid tool wear and ensure smooth machining processes.

4. Welding

Welding 6061 aluminum requires attention to detail, as the alloy's heat-affected zone can be sensitive to cracking. Proper filler material selection and heat input control are essential for successful welding.

In summary, 6061 aluminum discs are chosen when a balance of strength, corrosion resistance, and machinability is essential for the application.

Whether in aerospace, automotive, marine, or architectural industries, 6061 aluminum discs offer a versatile and reliable material solution.

As a part of the 6000 Series Aluminum discs, they represent a family of alloys with specific characteristics tailored to various needs. When the requirements call for a material that offers strength, corrosion resistance, and ease of processing, 6061 aluminum discs stand as a reliable choice.