- Introduction to 6005 Aluminum Plate

- Applications of 6005 Aluminum Plate

- 6005 Aluminum Processing and Fabrication

- 6005 Aluminum Plate Specifications and Standards

- Comparison with Other Aluminum Alloys

Aluminum is a versatile and widely used material in various industries due to its excellent combination of properties, including lightweight, corrosion resistance, and good mechanical properties.

One specific aluminum alloy that finds applications in a variety of fields is 6005 aluminum. In this comprehensive guide, we will explore 6005 aluminum plate/sheet in detail, covering its composition, properties, applications, processing, and more.

Introduction to 6005 Aluminum Plate

6005 Aluminum Plate Composition

6005 aluminum plate belongs to the 6xxx series of aluminum plates. Its chemical composition primarily consists of aluminum (Al), with the addition of other alloying elements, including magnesium (Mg) and silicon (Si). The composition of 6005 aluminum plate is approximately as follows:

- Aluminum (Al): 97.0% - 99.0%

- Magnesium (Mg): 0.40% - 0.70%

- Silicon (Si): 0.60% - 0.90%

- Iron (Fe): 0.0% - 0.35%

- Copper (Cu): 0.0% - 0.10%

- Manganese (Mn): 0.0% - 0.10%

- Chromium (Cr): 0.0% - 0.15%

- Zinc (Zn): 0.0% - 0.10%

- Other Elements: 0.05% each, 0.15% total maximum

This composition imparts the alloy with specific properties and characteristics that make it suitable for various applications.

Properties of 6005 Aluminum Plate

6005 aluminum plate possesses a range of physical and mechanical properties that make it a desirable material for a variety of industries. Some key properties include:

- Density: The density of 6005 aluminum is approximately 2.71 g/cm³, making it relatively lightweight.

- Strength: The alloy exhibits good strength properties, particularly when heat-treated.

Typical tensile strength for 6005-T5 is around 200 MPa, while 6005-T6 can reach approximately 270 MPa.

6005 Aluminum Plate Advantages

6005 aluminum plate/sheet offers several advantages, which contribute to its popularity in different industries:

- Good Strength-to-Weight Ratio: It provides a favorable strength-to-weight ratio, making it suitable for lightweight structural components.

- Corrosion Resistance: While not as corrosion-resistant as some other aluminum alloys, it offers sufficient corrosion resistance for many applications and can be improved with appropriate treatments.

- Machinability: It is easy to machine and process, making it versatile for various manufacturing processes.

- Weldability: 6005 aluminum plate is weldable, allowing for easy assembly and joining in structural applications.

- Formability: Its excellent extrudability allows for complex and customized shapes.

- Cost-Effective: It is often more affordable than some high-end aluminum alloys, making it an attractive choice for cost-conscious projects.

Disadvantages of 6005 Aluminum Plate

Despite its many advantages, 6005 aluminum plate also has some limitations:

- Moderate Corrosion Resistance: It may not be suitable for highly corrosive environments without additional protective measures.

- Lower Strength than Some Alloys: While it offers good strength, it may not meet the requirements of applications demanding the highest strength levels.

- Limited Heat-Treatability: 6005 aluminum plate is not as heat-treatable as some other plates, such as 6061, which can limit its strength enhancement potential.

Now that we've covered the basics of 6005 aluminum plate, let's explore its applications in more detail.

Applications of 6005 Aluminum Plate

6005 aluminum plate is a versatile alloy that finds applications in various industries due to its balance of properties. Some of the key sectors where 6005 aluminum plate is commonly used include:

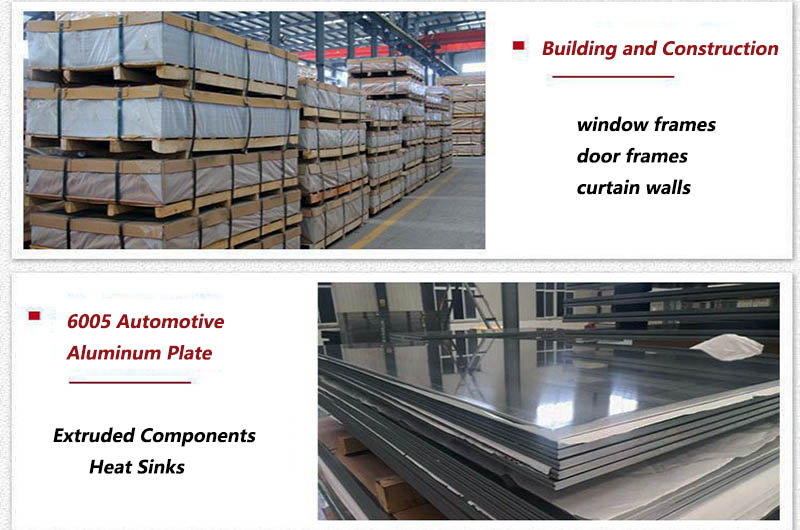

1. Building and Construction

One of the primary applications of 6005 aluminum is in the building and construction industry. It is utilized for the fabrication of various structural components, including:

- Architectural Extrusions: 6005 aluminum is often extruded into custom profiles used for architectural and decorative purposes, such as window frames, door frames, and curtain walls.

- Structural Beams: The alloy's good strength-to-weight ratio makes it suitable for structural beams and supports in buildings.

- Roofing Systems: It is used in the construction of roofing systems and canopies.

2. 6005 Automotive Aluminum Plate

6005 aluminum is also found in the automotive sector, where its lightweight and formability are highly valued. Applications include:

- Extruded Components: Various extruded components, such as car body frames and structural parts, are made from 6005 aluminum.

- Heat Sinks: The alloy's good thermal conductivity makes it suitable for heat sinks in automotive applications.

3. Transportation

In the broader transportation industry, 6005 aluminum is used for manufacturing various components in road, rail, and marine vehicles, such as:

- Bicycle Frames: Due to its lightweight properties, 6005 aluminum is used in the production of bicycle frames.

- Truck and Trailer Frames: It is also used in the construction of truck and trailer frames.

4. Consumer Goods

Consumer goods often incorporate 6005 aluminum for its aesthetic appeal and ease of fabrication. Common applications include:

- Furniture: The alloy is used to create lightweight, durable furniture frames and components.

- Sporting Goods: It can be found in the manufacturing of sporting equipment like bicycle frames, ski poles, and more.

- Electronics: 6005 aluminum is employed in the construction of electronic enclosures and components.

5. Industrial Equipment

In various industrial sectors, 6005 aluminum is employed for its strength and machinability. Applications include:

- Conveyor Systems: It is used for conveyor system components and frames.

- Machine Parts: Machine components that require a combination of strength and formability can be made from 6005 aluminum.

These are just a few examples of the many applications of 6005 aluminum. Its versatility, ease of fabrication, and cost-effectiveness make it a preferred choice for a wide range of industries.

6005 Aluminum Processing and Fabrication

Processing and fabricating 6005 aluminum involve various methods to shape and form the material according to specific application requirements. Here are some key processes involved:

1. Extrusion

Extrusion is one of the most common methods used to shape 6005 aluminum. The alloy's excellent extrudability allows it to be easily formed into complex profiles. The process typically involves the following steps:

- Billet Preparation: A cylindrical billet of 6005 aluminum is heated to a suitable temperature for extrusion.

- Extrusion: The billet is pushed through a die, which imparts the desired shape to the aluminum.

- Cooling: The extruded profile is cooled to room temperature.

- Cutting and Machining: The extruded pieces are cut to the required lengths and may undergo additional machining for precise dimensions.

2. Welding

6005 aluminum is weldable using various methods, including TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and resistance welding. Welding is a critical process in joining 6005 aluminum components to create larger structures or assemblies.

- TIG welding is often preferred for its precision and control, making it suitable for applications where the appearance of the weld is crucial.

- MIG welding is faster and can be used for thicker sections, making it suitable for structural applications.

3. Machining

Machining involves cutting, drilling, and shaping 6005 aluminum using various tools and techniques. It is a common method for achieving precise dimensions and shapes in components. The alloy's good machinability ensures that it can be easily worked with standard machine tools.

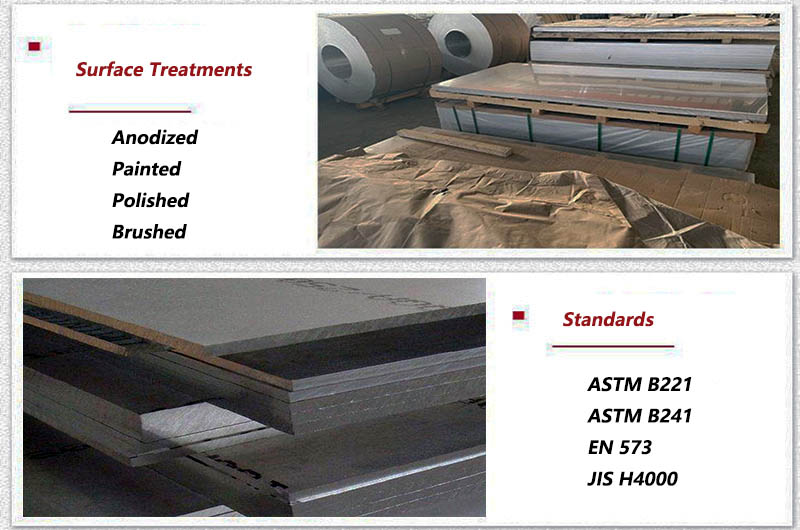

4. Surface Treatments

To enhance the corrosion resistance and appearance of 6005 aluminum components, various surface treatments can be applied, including:

- Anodizing: Anodizing creates a protective oxide layer on the surface, improving corrosion resistance and providing an opportunity for coloring.

- Painting and Powder Coating: These methods can be used for both aesthetic and protective purposes.

- Chemical Conversion Coatings: Chemical treatments can be applied to form a protective layer on the surface.

- Polishing and Brushing: These processes are used to improve the visual appeal of the aluminum.

The choice of processing and fabrication methods depends on the specific requirements of the application and the desired properties of the final product.

6005 Aluminum Plate Specifications and Standards

Aluminum alloys, including 6005, are subject to various industry and international standards. These standards help ensure the quality and consistency of the material. Here are some important specifications and standards related to 6005 aluminum:

1. ASTM Standards

- ASTM B221: This standard covers aluminum and aluminum-alloy extruded bars, rods, wire, profiles, and tubes. It provides detailed specifications for the chemical composition, mechanical properties, and tolerances for various aluminum alloys, including 6005.

- ASTM B241: ASTM B241 specifies seamless aluminum pipe and aluminum-alloy pipe. While it may not be specific to 6005, it is important to consider when selecting aluminum pipes for specific applications.

2. Other International Standards

- EN 573: European standard EN 573 provides specifications for wrought aluminum and aluminum alloys. It covers the chemical composition and mechanical properties of various aluminum alloys, including 6005.

- JIS H4000: Japanese Industrial Standard (JIS) H4000 is the standard for aluminum and aluminum alloys in Japan. It provides detailed information about the properties and specifications of aluminum materials, including 6005.

When sourcing 6005 aluminum, it's essential to ensure that it complies with the relevant standards and specifications that apply to your specific application. Your supplier should be able to provide you with material that meets these requirements.

Comparison with Other Aluminum Alloys

To further aid in decision-making, it's essential to compare 6005 aluminum with other commonly used aluminum alloys. In particular, let's examine its comparisons with 6061 and 6063 aluminum alloys, which are often used for similar applications.

6005 vs 6061 Aluminum

6005 and 6061 are both popular aluminum alloys, but they have distinct differences:

- Strength: 6061 aluminum generally has higher strength compared to 6005, particularly when both are in their T6 temper. This makes 6061 more suitable for applications requiring greater strength.

- Heat-Treatability: 6061 is highly heat-treatable, allowing for substantial strength improvements through heat treatment. 6005 offers some heat-treatability but not to the same extent.

- Corrosion Resistance: Both alloys offer similar levels of corrosion resistance, but 6061 may be preferred for applications in more aggressive environments due to its higher strength.

- Machinability: 6005 and 6061 are both machinable, but 6005 is often considered slightly more machinable.

- Cost: 6005 is typically more cost-effective than 6061, which can be a deciding factor for budget-conscious projects.