- 5754 Aluminum Disc Circle Introduction

- The Composition of 5754 Aluminum Disc Circle

- 5754 Aluminum Disc Circle Physical and Mechanical Properties

- Applications of 5754 Aluminum Discs

- How to Choose Aluminum Discs

- Conclusion

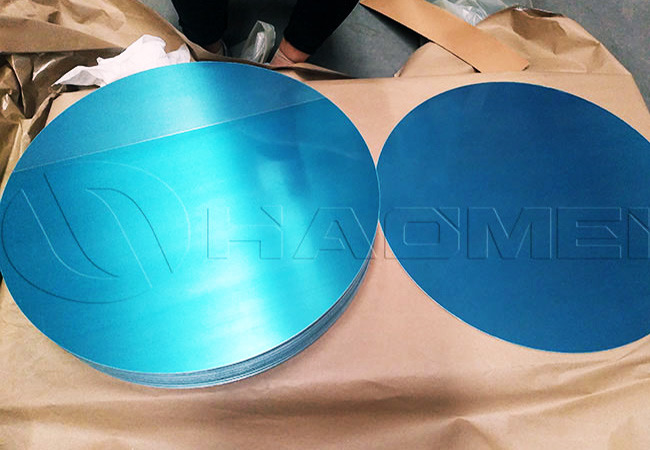

5754 Aluminum Disc Circle Introduction

Aluminum is one of the most versatile and widely used metals in various industries due to its exceptional properties, including its lightweight nature, corrosion resistance, and excellent heat conductivity.

Among the numerous aluminum alloys available, 5754 aluminum stands out for its unique combination of attributes.

In this comprehensive article, we will delve deep into the world of 5754 aluminum discs, exploring their composition, properties, applications, and advantages, shedding light on why they are favored in various industries.

The Composition of 5754 Aluminum Disc Circle

5754 aluminum belongs to the 5xxx series of aluminum alloys, which are known for their excellent corrosion resistance and moderate strength. The primary alloying element in 5754 aluminum is magnesium, with the chemical composition typically consisting of approximately 2.6% to 3.6% magnesium.

Additionally, 5754 aluminum contains small amounts of other elements, including manganese, chromium, and iron. This composition provides the alloy with its unique set of properties that make it highly sought after in various applications.

5754 Aluminum Disc Circle Physical and Mechanical Properties

1. 5754 Aluminum Disc Circle Strength and Toughness

5754 aluminum discs offer a good balance between strength and toughness. With a tensile strength of around 228-275 MPa, this alloy is well-suited for applications that require moderate structural strength.

The impressive combination of strength and toughness makes it ideal for industries where resilience and durability are key, such as transportation and construction.

2. 5754 Aluminum Disc Circle Corrosion Resistance

One of the standout features of 5754 aluminum is its exceptional corrosion resistance. The high magnesium content in this alloy forms a protective oxide layer on the surface, making it highly resistant to atmospheric and marine environments.

This property is particularly valuable in applications exposed to harsh weather conditions, like shipbuilding, offshore structures, and chemical processing.

3. 5754 Aluminum Disc Circle Formability

5754 aluminum can be easily formed, bent, and shaped without compromising its mechanical properties. This formability is a crucial factor in its use for manufacturing processes like spinning, stamping, and deep drawing.

The ability to create intricate shapes and designs is one of the reasons why 5754 aluminum discs are so popular in the production of kitchen utensils, lighting fixtures, and automotive components.

4. 5754 Aluminum Disc Circle Weldability

Welding is another area where 5754 aluminum excels. It can be readily welded using various methods, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and resistance welding.

This weldability makes it a preferred choice for fabricating complex structures and assemblies.

Applications of 5754 Aluminum Discs

The versatility of 5754 aluminum discs allows them to be used in a wide range of applications across different industries. Here are some of the notable sectors where this alloy shines:

1. 5754 Aluminum Discs for Automotive Industry

5754 aluminum discs are widely used in the automotive industry for the production of various components. These include fuel tanks, panels, chassis parts, and wheel rims.

The combination of lightweight properties and corrosion resistance makes it an excellent choice for improving fuel efficiency and ensuring the longevity of vehicle parts.

2. 5754 Aluminum Discs for Marine and Offshore Applications

The marine and offshore industries demand materials that can withstand the harsh conditions of saltwater and corrosive environments. 5754 aluminum's exceptional corrosion resistance makes it a preferred material for shipbuilding, offshore platforms, and other maritime applications.

3. 5754 Aluminum Discs for Food Industry

In the food industry, hygiene and corrosion resistance are critical. 5754 aluminum discs are commonly used to manufacture cookware, utensils, and food processing equipment.

The metal's non-reactive nature ensures that it doesn't compromise the quality or taste of food, making it a safe and practical choice.

4. 5754 Aluminum Discs for Building and Construction

5754 aluminum's combination of strength and corrosion resistance finds application in the construction industry. It is used for roofing materials, cladding, and structural components in both residential and commercial buildings.

The lightweight nature of this alloy also makes it easier to work with, reducing labor and transportation costs.

5. 5754 Aluminum Discs for Aerospace

While 5754 aluminum may not be as prevalent in aerospace as other high-strength alloys like 2024 or 7075, it still finds use in certain applications.

Its lightweight properties, corrosion resistance, and formability make it suitable for interior components and structures in aircraft.

6. 5754 Aluminum Discs for Industrial Equipment

Various industrial equipment, such as storage tanks, pressure vessels, and chemical processing equipment, benefit from the corrosion resistance and formability of 5754 aluminum.

Its weldability is also advantageous in fabricating custom solutions for specific industrial needs.

How to Choose Aluminum Discs

Choosing the right aluminum discs for your specific needs involves considering several key factors to ensure that you select the most suitable material for your application. Whether you are looking for aluminum discs for cookware, industrial equipment, or any other purpose, here are some important considerations to keep in mind:

1. Alloy Selection

Aluminum comes in various alloy compositions, each with unique properties and characteristics. Consider the following alloys and their properties:

1xxx Series: These alloys are almost pure aluminum and have excellent corrosion resistance but are not very strong. They are suitable for applications that prioritize corrosion resistance, such as chemical equipment.

3xxx Series: Alloys in this series are typically used for their excellent formability and resistance to corrosion. They are often used in applications like automotive parts and cookware.

5xxx Series: These alloys, including 5754 aluminum, offer a good balance between strength and corrosion resistance. They are widely used in marine, automotive, and construction industries.

6xxx Series: These alloys are known for their extrudability and are commonly used in structural applications like building and construction.

7xxx Series: These alloys offer high strength and are often used in aerospace and high-stress structural applications.

2. Application Requirements

Consider the specific requirements of your application, such as:

Corrosion Resistance: If your application is exposed to corrosive environments, choose an alloy with high corrosion resistance, such as 5xxx series aluminum.

Strength: Different applications require varying levels of strength. Determine the required tensile strength and yield strength for your project and select an alloy accordingly.

Formability: If your application involves shaping or forming the aluminum, select an alloy with good formability, like 3xxx or 5xxx series.

Heat Resistance: Some applications, like cookware, require aluminum with good heat resistance to prevent warping or deformation at high temperatures.

3. Thickness and Dimensions

Consider the required thickness and dimensions of the aluminum discs. Ensure that the discs you choose meet the size and thickness specifications for your project.

Keep in mind that thicker discs will generally have greater strength but may be less suitable for deep drawing or forming.

4. Surface Finish

Determine the desired surface finish for your application. Aluminum discs can come with various surface treatments, such as mill finish, anodized, or painted.

The choice depends on your specific application and aesthetic preferences.

5. Cost

Consider your budget constraints. Some aluminum alloys and finishes are more expensive than others. Balance the desired properties with your budget to find the most cost-effective solution.

6. Environmental Considerations

If environmental sustainability is a concern, opt for recycled aluminum or choose an alloy that is highly recyclable. Aluminum is known for its recyclability, and using recycled materials can contribute to a more sustainable production process.

7. Regulatory Compliance

Ensure that the aluminum discs you select comply with relevant industry standards and regulations, especially if your application has specific safety or quality requirements.

Conclusion

5754 aluminum discs, with their unique composition and remarkable properties, have found their way into a wide range of industries, offering solutions to various challenges.

The alloy's excellent corrosion resistance, lightweight nature, formability, and weldability make it a valuable material for applications as diverse as automotive, marine, food, construction, aerospace, and industrial equipment.

Moreover, the advantages of 5754 aluminum, such as recyclability, further add to its appeal as a sustainable material choice.

As technology and manufacturing techniques continue to evolve, the use of 5754 aluminum and other aluminum alloys is likely to expand even further, opening up new possibilities and applications across industries.

Its ability to meet the ever-changing demands of different sectors while contributing to a more sustainable future cements its place as a versatile and indispensable material in modern engineering and design.