- Understanding 5454 Aluminum Alloys

- 5454 Aluminum Disc Specifications

- Properties of 5454 Aluminum Disc

- Applications of 5454 Aluminum Disc

- Manufacturing Processes of 5454 Aluminum Discs

- Environmental Considerations

- Conclusion

Aluminum is a remarkable material known for its exceptional properties, versatility, and wide range of applications. Among the various aluminum alloys, the 5454 aluminum disc stands out as an interesting and widely used variant.

Understanding 5454 Aluminum Alloys

To grasp the significance of the 5454 aluminum disc, it's important to understand the concept of aluminum alloys. Aluminum is a lightweight metal with a multitude of applications, but it's often too soft and ductile in its pure form for certain tasks.

The 5454 aluminum alloy is part of this family and is primarily composed of aluminum, with magnesium as the primary alloying element. Let's explore this alloy in depth.

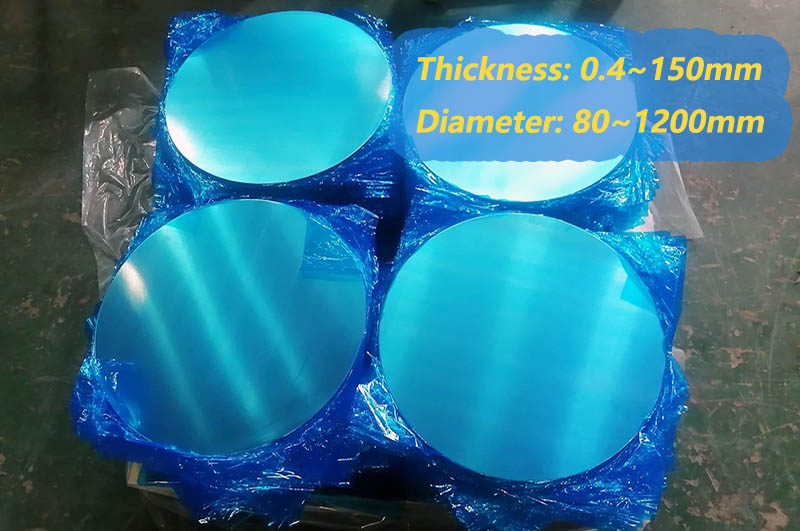

5454 Aluminum Disc Specifications

- Temper: O, H12, H14, H16, H18, H22, H24, H26, H32, H34

- Thickness: 0.4~150mm

- Diameter: 80~1200mm

- Surface:Mill finish

- Protection:paper inter layer, white film, blue film, black-white film, micro bound film, according yo your requirement.

- Surface:clean and smooth, no bright speck, corrosion, oil, slotted, etc.

Properties of 5454 Aluminum Disc

5454 Aluminum Disc Corrosion Resistance

The 5454 aluminum disc is known for its exceptional corrosion resistance, particularly in marine environments. The addition of magnesium to the alloy enhances its resistance to seawater and other corrosive substances. This property makes it an ideal choice for applications in the maritime industry, where exposure to saltwater and harsh weather conditions is common.

5454 Aluminum Disc Strength and Ductility

Despite its high corrosion resistance, the 5454 aluminum disc retains good mechanical properties. It offers a balance between strength and ductility, making it suitable for applications that require both. The alloy can be easily formed and welded, and it retains its structural integrity under various loads.

5454 Aluminum Disc Formability

5454 aluminum discs are highly formable, allowing manufacturers to shape them into a variety of configurations. This makes them versatile for various industries, such as automotive, aerospace, and construction. Their ability to be molded into different shapes without compromising their structural integrity is a valuable characteristic.

5454 Aluminum Disc Weldability

The weldability of 5454 aluminum is noteworthy. It can be readily welded using common methods such as MIG and TIG welding. This ease of welding is advantageous for fabricators who need to join aluminum components in various applications.

5454 Aluminum Disc Thermal Conductivity

Aluminum, in general, is an excellent conductor of heat, and the 5454 aluminum disc is no exception. This property is particularly useful in applications where efficient heat transfer is crucial, such as in the production of heat exchangers and radiators.

5454 Aluminum Disc Surface Finish

5454 aluminum discs typically have a smooth, reflective surface finish, making them visually appealing. This quality is advantageous in industries where aesthetics matter, such as architecture and design.

Applications of 5454 Aluminum Disc

1. 5454 Aluminum Disc Circle for Automotive Industry

The automotive sector is a significant consumer of 5454 aluminum discs. Their combination of strength, formability, and corrosion resistance makes them ideal for various components, including fuel tanks, body panels, and chassis components. Aluminum alloy wheels are another prominent application, thanks to the alloy's lightweight and stylish appearance.

2. 5454 Aluminum Disc Circle for Maritime and Offshore Industry

As mentioned earlier, 5454 aluminum discs excel in marine environments. They are used in the construction of boat hulls, decks, and other components that come into contact with seawater. Additionally, offshore structures such as oil rigs benefit from the alloy's ability to withstand harsh offshore conditions.

3. 5454 Aluminum Disc Circle for Construction and Architecture

In the construction industry, 5454 aluminum discs are employed in roofing, cladding, and curtain wall systems. Their corrosion resistance ensures longevity, and their formability allows for innovative and aesthetically pleasing designs in modern architecture.

4. 5454 Aluminum Disc Circle for Aerospace Industry

Aerospace applications require materials that are lightweight, strong, and corrosion-resistant. The 5454 aluminum alloy finds use in aircraft components, particularly in structures and panels where weight savings are crucial. Its combination of properties contributes to fuel efficiency and overall performance.

5. 5454 Aluminum Disc Circle for Heat Exchangers and Radiators

The thermal conductivity of 5454 aluminum is put to good use in the production of heat exchangers and radiators. These components are essential in a wide range of applications, including HVAC systems, refrigeration units, and automotive cooling systems.

6. 5454 Aluminum Disc Circle for General Manufacturing

5454 aluminum discs are employed in a variety of manufacturing processes, including stamping, spinning, and deep drawing. They are utilized for the production of cookware, lighting fixtures, and various consumer goods.

Manufacturing Processes of 5454 Aluminum Discs

1. Casting

The production of 5454 aluminum discs often begins with casting. The alloy is melted and cast into various shapes, which can be further processed into discs. Casting can be done through different methods, such as sand casting or die casting.

2. Rolling

After casting, the aluminum is rolled into the desired thickness and dimensions. The rolling process can be performed at various temperatures, including hot rolling and cold rolling, depending on the specific requirements of the final product.

3. Annealing

Annealing is a heat treatment process that helps relieve internal stresses and improve the mechanical properties of the aluminum discs. This step is crucial to enhance the alloy's formability and ductility.

4. Cutting and Shaping

Once the aluminum is in the form of a flat sheet, it is cut into the desired size and shape. For discs, a cutting process is employed to create circular pieces with precise dimensions.

5. Surface Treatment

5454 aluminum discs may undergo surface treatments to improve their appearance and corrosion resistance. These treatments can include anodizing, polishing, or coating with protective layers.

6. Welding

In applications that require the joining of aluminum components, welding processes are utilized. The 5454 aluminum alloy is well-suited for welding, allowing for the fabrication of complex structures.

Environmental Considerations

1. Recyclability

One of the most significant environmental advantages of aluminum, including 5454 alloy, is its recyclability. Aluminum is 100% recyclable, meaning that it can be repeatedly melted down and reprocessed without any loss of quality. Recycling aluminum not only conserves energy but also reduces the need for mining and extraction of raw materials.

2. Reduced Carbon Footprint

The production of aluminum, compared to some other metals, has a relatively low carbon footprint. The recycling process is also energy-efficient, leading to further reduction in greenhouse gas emissions. In many cases, using recycled aluminum can provide substantial environmental benefits.

3. Resource Efficiency

Aluminum is derived from bauxite ore, which is abundant and widely available. As a result, aluminum production is less resource-intensive than other materials, making it a sustainable choice for various applications.

4. Durability

The corrosion resistance of 5454 aluminum discs contributes to their durability. This means that products made from this alloy have a longer service life, reducing the need for frequent replacements and, consequently, resource consumption.

5. Lightweight Design

The lightweight nature of aluminum, including the 5454 alloy, has a positive impact on reducing energy consumption in applications such as transportation. Lighter vehicles, aircraft, and structures require less fuel or energy to operate, leading to lower emissions and energy savings.

Conclusion

The 5454 aluminum disc, with its remarkable properties and wide range of applications, is a testament to the versatility and significance of aluminum alloys. Its combination of corrosion resistance, strength, formability, and weldability makes it a popular choice in industries as diverse as automotive, maritime, aerospace, construction, and manufacturing.

Furthermore, its environmentally friendly attributes, including recyclability, low carbon footprint, and resource efficiency, make it a sustainable material choice. As industries continue to prioritize sustainability and efficiency, the 5454 aluminum disc is sure to play an increasingly important role in shaping the future of materials engineering and manufacturing.

Its multifaceted nature, along with its ability to meet the demanding requirements of various sectors, ensures that the 5454 aluminum disc will remain a vital component in the modern world.