- 5052 Aluminum Disc Features

- 5052 Aluminum Circle Specifications

- 5052 Aluminum Disc Circle Mechanical Properties

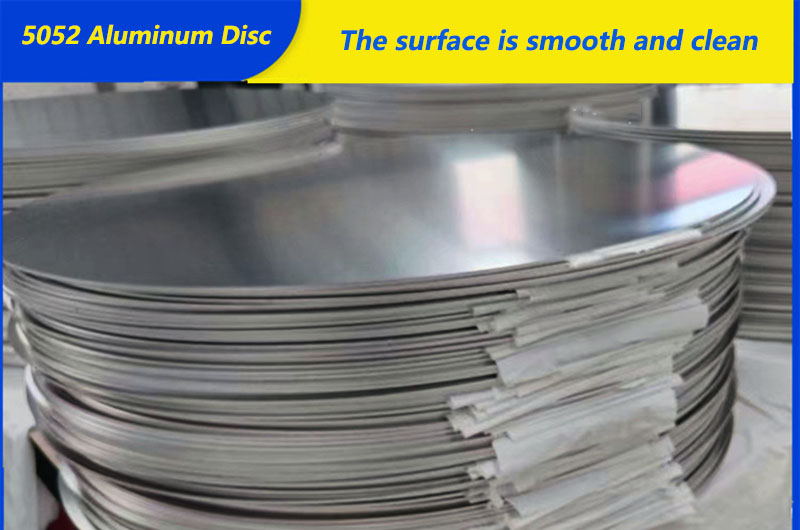

- 5052 Aluminum Disc Surface Treatments Type

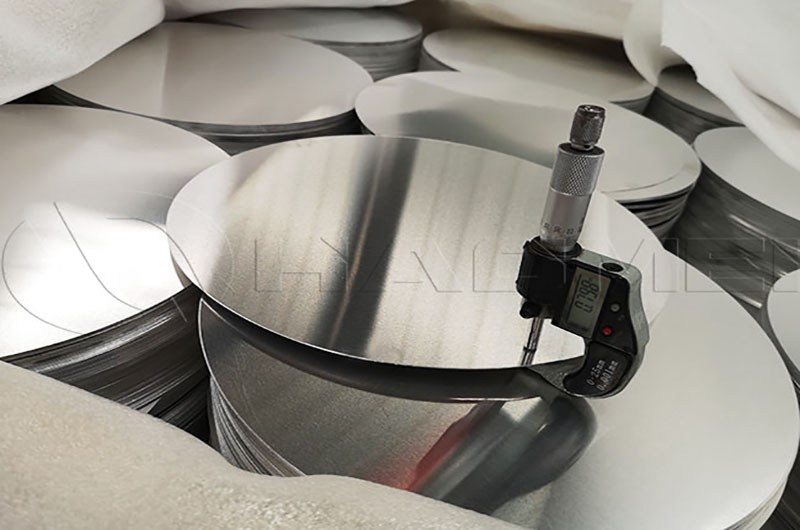

- 5052 Aluminum Circle Quality Inspection

- Typical 5052 Aluminum Discs

- 5052 Aluminum Disc Circle Applications

- 5052 Aluminum Circle Chemical Composition

- 5052 Aluminum Disc Production Process

- Frequently Asked Questions about 5052 Aluminum Disc Circle

5052 aluminum disc is a common aluminum alloy disc material, which is composed of aluminum, magnesium and other alloying elements. It has excellent corrosion resistance, processability and strength properties, and is often used in the manufacture of various products that require high strength and corrosion resistance.

5052 aluminum discs belong to the 5 series aluminum alloy. 5 series aluminum products have good formability, corrosion resistance, weldability and medium strength.

5052 aluminum discs are pre-processed products after continuous stamping of aluminum coils. They are widely used in lamps, kitchenware, electronic and electrical casings, traffic signs, etc.

5052 Aluminum Disc Features

- Good corrosion resistance : 5052 aluminum discs have good corrosion resistance and can be used in humid and corrosive environments.

- Good processing performance : 5052 aluminum disc has good processing performance, and can be processed by deep drawing, shearing, stamping, welding and other processing methods.

- High strength : 5052 aluminum disc has high strength and rigidity, and can be used to manufacture products that need to bear large loads.

- Good weldability : 5052 aluminum discs have good weldability and can be connected by various welding methods.

5052 aluminum alloy is an AL-Mg series aluminum alloy and is the most widely used rust-proof aluminum.

- 1. High fatigue strength

- 2. High plasticity

- 3. Cannot be strengthened by heat treatment

- 4. Good plasticity during semi-cold work hardening

- 5. Low plasticity during cold work hardening

- 6. Poor machinability

5052 Aluminum Circle Specifications

- Temper: O, H32, H34, H111

- Thickness: 0.5mm-6.0mm

- Diameter: 100mm-1200mm

- Equivalent alloy name: a5052, 5052a, aa5052, 5052aa, al5052, al5052

5052 Aluminum Circle Thickness Tolerance

| Thickness tolerance | mm |

|---|---|

| diameter<455mm | +/- 0.05 mm |

455|

+/- 0.1 mm

|

|

| Diameter >1000 mm | +/- 0.2 mm |

5052 Aluminum Circle Diameter Tolerance

| Nominal Diameter | Tolerance |

|---|---|

| Multiple of 5mm | +/- 0.5mm |

| Not multiple of 5mm | +/- 3.0mm |

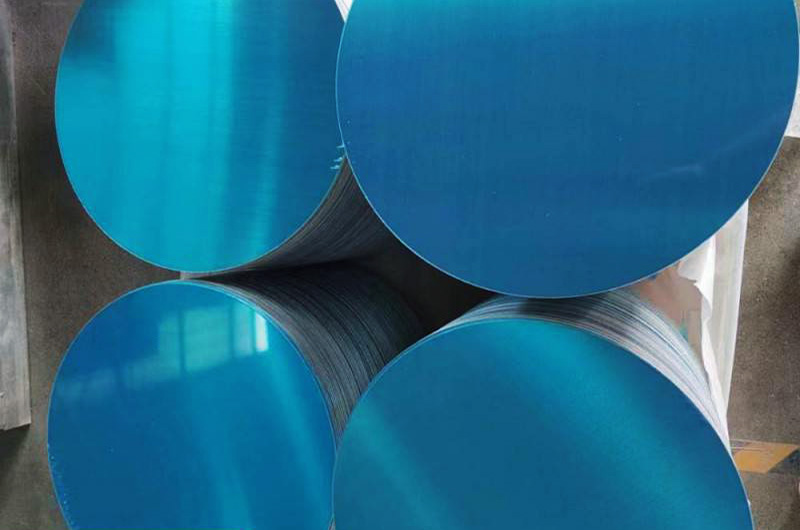

Surface Protection: With PE/PVC coating on main side (if specified)

5052 Aluminum Disc Circle Mechanical Properties

| Tensile strength | 210 - 260 MPa |

|---|---|

| Yield strength | 83 - 228 MPa |

| Elongation | 6% - 12% |

| Hardness (Brinell) | 47 - 59 HB |

5052 Aluminum Disc Surface Treatments Type

5052 aluminum discs, like other aluminum alloys, can undergo various surface treatments to enhance their appearance, corrosion resistance, and other properties. Common surface treatments for 5052 aluminum discs include:

- 5052 Anodized Aluminum Discs

- 5052 Color Coated Aluminum Discs

- 5052 Embossed Aluminum Discs

- 5052 Mirror Aluminum Discs

- 5052 Brushed Aluminum Discs

5052 Anodized Aluminum Discs

These are 5052 aluminum discs that have undergone an anodizing process. Anodizing creates a controlled oxide layer on the surface of the aluminum, which enhances its corrosion resistance and provides the option for coloring.

Anodized aluminum discs are commonly used in architectural elements, cookware, electronic enclosures, and decorative items due to their durability and attractive appearance.

5052 Color Coated Aluminum Discs

These discs have been coated with a colored finish, typically through processes like powder coating or liquid painting. The coating can be applied in a variety of colors and textures to suit specific applications.

Color-coated aluminum discs are frequently used in signage, automotive parts, and architectural projects where both aesthetics and corrosion resistance are essential.

5052 Mirror Aluminum Discs

These discs have been meticulously polished to create a mirror-like finish. The polishing process involves progressively finer abrasives to achieve a highly reflective surface.

Mirror aluminum discs are chosen for their aesthetic appeal and are employed in decorative architectural features, lighting fixtures, and automotive accents.

5052 Brushed Aluminum Discs

Brushed aluminum discs have a textured surface achieved by brushing the metal with abrasive materials. The result is a series of fine, parallel lines or a satin-like finish.

These discs are often used for decorative purposes in architectural elements, appliances, and consumer products where a distinctive appearance is desired.

5052 Embossed Aluminum Discs

Embossed aluminum discs have patterns or textures pressed into their surface. The embossing can serve both decorative and functional purposes, such as enhancing grip.

These discs find use in applications such as non-slip flooring, decorative trim, and identification tags.

5052 Aluminum Circle Quality Inspection

- Raw Material Quality : 5052 aluminum wafer raw materials should meet national standards and requirements, with stable chemical composition and uniform physical properties.

- Processing Technology : The manufacturing process of 5052 aluminum disc adopts advanced production technology and equipment to ensure the accuracy and quality of the product. The processing technology includes multiple links such as casting, rolling, stretching, shearing, bending, etc., and each link is strictly controlled.

- Surface Quality : The surface of the 5052 aluminum disc is smooth and clean, without defects such as cracks, bubbles and inclusions. Surface quality directly affects the service life and aesthetics of 5052 aluminum discs.

- Dimensional Accuracy : The dimensional accuracy of 5052 aluminum discs meets national standards and customer requirements. Dimensional accuracy includes diameter, thickness, flatness, etc., for precise detection and control.

- Performance Stability : The performance stability of 5052 aluminum discs can maintain excellent performance stably for a long time.

Haomei Aluminum strictly controls the quality of 5052 aluminum discs.

- High purity: Cast in strict accordance with 5052 chemical composition and manufactured through strict hot rolling and cold rolling processes.

- High precision: uniform and accurate thickness, small diameter error.

- Good surface quality: no oil stains, no scratches, no other marks, smooth surface.

- Low ear rate: All 5052 aluminum circles have undergone strict ear rate testing to ensure you have worry-free production.

- Long service life: good antioxidant effect.

Typical 5052 Aluminum Discs

5052 H32 Aluminum Disc

5052 H32 aluminum disc has been semi-hardened and has excellent bending and tensile strength. It is often used in the manufacture of components and shells in the fields of automobiles, aircraft, ships, buildings, bags, etc.

- Application : Specifications : Common specifications are thickness 0.5mm-6mm, diameter 100mm-1200mm.

- Unique advantages : medium hardness and strength, good processability and corrosion resistance, suitable for applications requiring medium strength and corrosion resistance.

| State | 5052 H32 |

|---|---|

| Tensile Strength | 210 MPa |

| Yield Strength | 160 MPa |

| Elongation | 12% |

5052 H34 Aluminum Disc

5052 H34 discs are stronger than 5052 H32 discs, have higher tensile strength and yield strength, and are suitable for applications requiring higher strength and corrosion resistance, such as marine equipment, aircraft components, pressure vessels, etc.

- Specifications : Commonly used specifications are thickness 0.5mm-6mm, diameter 100mm-1200mm.

- Unique advantages : It has high hardness and strength, good processing performance and corrosion resistance, and is suitable for applications requiring high strength and corrosion resistance.

| State | 5052 H34 |

|---|---|

| Tensile Strength | 230 MPa |

| Yield Strength | 180 MPa |

| Elongation | 10% |

5052 H36 Aluminum Disc

The 5052 H36 aluminum disc has a stronger semi-hardening treatment, which has higher strength and hardness, and is suitable for structural parts and aircraft parts that require high strength and high corrosion resistance.

- Specifications : Commonly used specifications are thickness 0.5mm-6mm, diameter 100mm-1200mm.

- Unique advantages : higher hardness and strength, good processability and corrosion resistance, suitable for applications requiring higher strength and corrosion resistance.

| State | 5052 H36 |

|---|---|

| Tensile Strength | 250 MPa |

| Yield Strength | 200 MPa |

| Elongation | 8% |

5052 H38 Aluminum Disc

5052 H38 aluminum discs are stronger semi-hardened, with the highest strength and hardness, suitable for applications requiring extremely high strength and good corrosion resistance, such as aerospace, shipbuilding and other fields.

- Specifications : Commonly used specifications are thickness 0.5mm-6mm, diameter 100mm-1200mm.

- Unique advantages : It has the highest hardness and strength, good processability and corrosion resistance, and is suitable for applications requiring the highest strength and corrosion resistance.

| State | 5052 H38 |

|---|---|

| Tensile Strength | 270 MPa |

| Yield Strength | 220 MPa |

| Elongation | 7% |

5052 Aluminum Disc Circle Applications

5052 aluminum discs have a wide range of applications. This alloy disc is suitable for many fields such as electronics, daily chemicals, medicine, culture and education, and auto parts. We usually use it to make hardware products such as road signs, oil-tight hatch covers, lampshades, etc.

| Alloy | 5052DC | 5052-H32 |

|---|---|---|

| thickness | 0.6-4.0mm | 1.0-2.0mm |

| diameter | 135-960mm | 600mm-800mm |

| surface | anodizing | anodizing |

| application | Cookware, road sign, lighting | Traffic sign, oil tank hatchcover |

5052 Aluminum Circle for Manufacturing Auto Parts

Usually, thicker 5052 aluminum discs are used. 5052 discs can be formed by deep drawing, stamping and other processes to make parts of various shapes, such as automobile doors, wheels, frames, exhaust pipes, etc.

- Advantages : Improve the lightweight and corrosion resistance of automobiles

- Alloy state : H32

- Thickness : 0.5-6.0mm

- General diameter : within the range of 100-1200mm

5052 Aluminum Circle for Ship Building

Shipbuilding usually requires the use of relatively thick 5052 aluminum discs. The 5052 discs are made into aluminum discs of various specifications and shapes through cutting and cutting processes, such as hulls, decks, cabins, bridges, etc.

- Advantages : Improve the lightweight and corrosion resistance of ships

- Alloy state : H32

- Thickness : 1.0-8.0mm

- Diameter : 200-1500mm

5052 Aluminum Circle for Aircraft Parts

Aircraft parts usually need to use thinner 5052 aluminum discs, which can be formed by deep drawing, stamping and other processes to make parts of various shapes, such as aircraft shells, landing gear, wings, fuel tanks, and cable tunnels wait.

- Advantages : Improve the lightweight and corrosion resistance of the aircraft

- Status : H32

- Thickness : 0.5-4.0mm

- Diameter : 200-1000mm

5052 Aluminum Circle for Building Materials

Building materials usually need to use relatively thin 5052 aluminum circles. The circles can be made into aluminum circles of various specifications and shapes by cutting, cutting and forming processes, such as aluminum alloy doors and windows, curtain walls, roofs, aluminum ceilings and other buildings. Material.

- Advantages : Improve the weather resistance and aesthetics of buildings

- Alloy state : H32

- Thickness : 0.5-6.0mm

- Diameter : 100-1200mm

5052 Aluminum Circle for Chemical Equipment

Chemical equipment usually needs to use relatively thick 5052 aluminum discs. The discs can be made into aluminum discs of various specifications and shapes by cutting, cutting and forming processes, such as pressure vessels, heat exchangers, distillation towers, etc. In addition, the wafer can be surface treated, such as anodizing, oxidation, etc., to improve its corrosion resistance and strength properties.

- Advantages : Improve the corrosion resistance and strength performance of the equipment

- Alloy state : H34

- Thickness : 1.0-8.0mm

- Diameter : 200-1500mm

5052 Aluminum Circle Chemical Composition

| Magnesium (Mg) | 2.2% - 2.8% |

|---|---|

| Chromium (Cr) | 0.15% - 0.35% |

| Iron (Fe) | 0.4% max |

| Manganese (Mn) | 0.1% max |

| Silicon (Si) | 0.25% max |

| Copper (Cu) | 0.1% max |

| Zinc (Zn) | 0.1% max |

| Titanium (Ti) | 0.15% max |

| Others | 0.05% max each, 0.15% max total |

5052 Aluminum Disc Production Process

- Aluminum ingot/master alloy

- aluminum melting furnace

- aluminum plate

- Hot rolled (direct casting) or cold rolled (chill cast)

- punching

- Annealing furnace

- final test

- Package

- deliver goods

Frequently Asked Questions about 5052 Aluminum Disc Circle

NO1. Is 5052 Aluminum Suitable for Food Contact Applications?

Yes, 5052 aluminum is considered food-safe and is commonly used in cookware and kitchen utensils. However, it's important to ensure that any coatings or treatments applied to the aluminum are also food-safe.

NO2. How are 5052 Aluminum Disc Circles Manufactured?

They are typically manufactured through a process called blanking or stamping, where a large sheet of 5052 aluminum is cut into circular shapes using a hydraulic press or a stamping die. Additional processes like spinning and deep drawing can be used to form these circles into desired shapes.

NO3. What is the Thickness Range Available for 5052 Aluminum Disc Circles?

The thickness of 5052 aluminum disc circles can vary, but typical thicknesses range from 0.5 mm (0.02 inches) to several millimeters, depending on the application.

NO4. Is 5052 Aluminum Recyclable?

Yes, aluminum, including 5052 alloy, is highly recyclable. Recycling aluminum requires significantly less energy compared to producing it from raw materials, making it an environmentally friendly choice.

NO5. What are the Finishing Options for 5052 Aluminum Disc Circles?

5052 aluminum disc circles can be finished with various surface treatments, including anodizing, painting, or polishing, depending on the desired appearance and application requirements.

NO6. Is 5052 Aluminum Suitable for Outdoor Applications?

Yes, 5052 aluminum's corrosion resistance makes it suitable for outdoor applications. However, for extended exposure to harsh environments, additional protective coatings or treatments may be necessary.