- Understanding 5005 Aluminum Alloys

- Features of 5005 Aluminum Discs

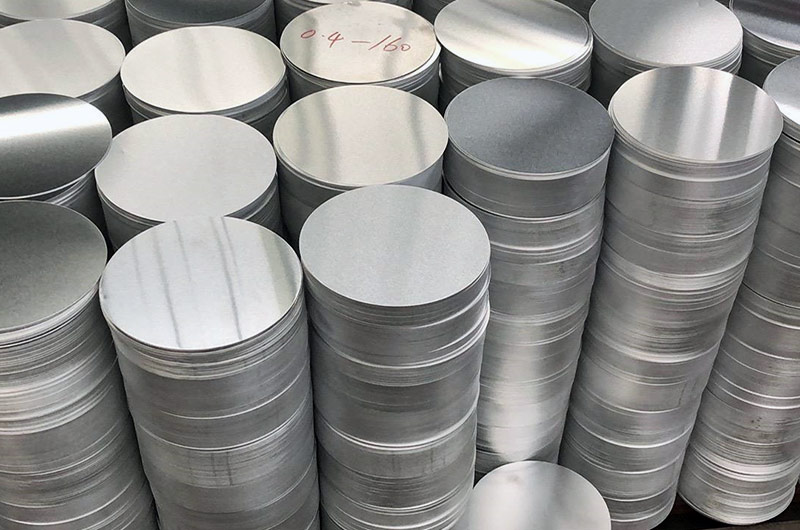

- 5005 Aluminum Disc Circle Specifications

- 5005 Aluminum Disc Quality Control

- Properties of 5005 Aluminum Disc

- Chemical Composition of 5005 Aluminum Disc

- 5005 Aluminum Disc Circle Surface Treatment Options

- Applications of 5005 Aluminum Disc

- When to Choose 5005 Aluminum Disc

- Production and Processing Precautions

- Conclusion

5005 alloy aluminum disc has higher strength, excellent formability and corrosion resistance, and can be processed by deep drawing and spinning methods.

Aluminum, a lightweight and versatile metal, is a cornerstone of modern industry and manufacturing. Among the myriad of aluminum alloys, the 5000 series is particularly noteworthy for its diverse range of applications and excellent properties.

Understanding 5005 Aluminum Alloys

Before diving into the specifics of the 5005 aluminum disc, it's essential to comprehend the concept of 5005 aluminum alloys.

The 5005 aluminum alloy is a member of the 5000 series, which is primarily alloyed with magnesium.

Corrosion Resistance 5005 has the same high general corrosion resistance as other non-heat treatable aluminum alloys. Like the 5000 series alloys, it also offers increased resistance to mildly alkaline conditions. The atmospheric corrosion resistance of 5005 is similar to that of 3003.

Features of 5005 Aluminum Discs

1. The drawing quality is good and the spinning quality is good.

2. Excellent wafer forming and anodizing performance.

3. The metal surface has excellent reflectivity and is suitable for polishing.

4. Anodizing is of good quality and versatile.

5. The surface of the disc is smooth, the edges are smooth, the texture is fine, and there is no bottom line after drawing.

5005 Aluminum Disc Circle Specifications

- Status: O, H12, H14, H16, H18, H22, H24, H26, H32, H34

- Thickness: 0.4~150mm

- Diameter: 80~1200mm

- Surface: polished

| Temper | 0.2% Proof Stress, MPa | Tensile Strength, MPa | Elongation % |

|---|---|---|---|

| O (annealed) | 35 | 105 – 145 | 12 – 22 |

| H12 | 95 | 125 – 165 | 2 – 8 |

| H14 | 115 | 145 – 185 | 1 – 6 |

| H16 | 135 | 165 – 205 |

5005 Aluminum Disc Quality Control

Aluminum round surface treatment: bright and smooth surface, no flow lines, slightly oiled to avoid white rust. Smooth, bright, no breaks, no scratches, no sludge

Material Quality: Completely free of defects such as white rust, oil spots, roll marks, edge damage, bows, dents, holes, broken wires, scratches, and no coil packs.

Properties of 5005 Aluminum Disc

5005 Aluminum Disc Corrosion Resistance

5005 aluminum discs exhibit excellent corrosion resistance, particularly in marine and saltwater environments. This property is a result of the magnesium content in the alloy, which forms a protective oxide layer on the surface, preventing corrosion.

5005 Aluminum Disc Strength and Ductility

The 5005 alloy offers a good balance of strength and ductility. It is easily formable, allowing it to be used in various applications where shaping and bending are required. This combination of properties makes it suitable for structural components and other diverse uses.

5005 Aluminum Disc Formability

One of the standout characteristics of 5005 aluminum is its exceptional formability. This makes it ideal for applications that demand intricate shapes and complex designs. It can be easily stamped, bent, and deep-drawn without compromising its structural integrity.

5005 Aluminum Disc Weldability

5005 aluminum is readily weldable using common methods such as MIG and TIG welding. This attribute is advantageous for applications requiring the joining of aluminum components, as it facilitates the fabrication of complex structures.

5005 Aluminum Disc Thermal Conductivity

Like all aluminum alloys, 5005 aluminum has excellent thermal conductivity. It is often used in heat transfer applications where efficient heat exchange is crucial, such as heat exchangers and radiators.

5005 Aluminum Disc Surface Finish

5005 aluminum discs typically have a smooth, reflective surface finish, making them visually appealing and well-suited for applications where aesthetics are essential.

Chemical Composition of 5005 Aluminum Disc

The 5005 aluminum disc primarily consists of aluminum, with magnesium as the primary alloying element. The chemical composition is typically as follows:

- Aluminum (Al): 97.5%

- Magnesium (Mg): 0.7%

- Manganese (Mn): 0.2%

- Chromium (Cr): 0.1%

- Iron (Fe): 0.3%

- Silicon (Si): 0.3%

- Copper (Cu): 0.2%

- Zinc (Zn): 0.25%

5005 Aluminum Disc Circle Surface Treatment Options

The surface treatment of 5005 aluminum discs can enhance their appearance, durability, and resistance to corrosion. Some common surface treatment options include:

5005 Anodized Aluminum Disc Circle

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. 5005 Anodized Aluminum Disc Circle can be customized to achieve various colors and degrees of protection, making it a popular choice for architectural and decorative applications.

5005 Painted and Powder Coated Aluminum Disc Circle

5005 aluminum can be painted or powder-coated to improve its appearance and protect it from environmental factors. 5005 Painted and Powder Coated Aluminum Disc Circle is often used in architectural and automotive applications.

5005 Polished Aluminum Disc Circle

Polishing can be applied to create a mirror-like finish on the surface of 5005 aluminum, making it suitable for decorative and high-end applications.

Chemical Conversion Coating

Chemical conversion coatings, such as chromate or phosphate coatings, are used to improve adhesion and corrosion resistance. They are common in aerospace and automotive applications.

Applications of 5005 Aluminum Disc

1. Architecture and Building

5005 aluminum discs are widely used in architectural applications, such as cladding, roofing, and decorative elements. Their corrosion resistance and ease of surface treatment make them a popular choice for buildings and structures.

2. Automotive Industry

In the automotive sector, 5005 aluminum discs are employed in various components, including fuel tanks, trim parts, and structural elements. Their combination of formability, corrosion resistance, and lightweight nature is advantageous in this sector.

3. Electrical Industry

The electrical industry utilizes 5005 aluminum for busbars, electrical enclosures, and components requiring excellent electrical conductivity and corrosion resistance.

4. Cookware and Kitchenware

5005 aluminum is used in the production of cookware and kitchenware due to its excellent formability, corrosion resistance, and thermal conductivity. Pots, pans, and utensils benefit from these properties.

5. Heat Exchangers

The thermal conductivity of 5005 aluminum is valuable in the production of heat exchangers. These components are used in HVAC systems, refrigeration units, and automotive cooling systems.

6. General Manufacturing

The versatile nature of 5005 aluminum makes it suitable for various manufacturing processes, including stamping, spinning, and deep drawing. It is used in the production of a wide range of consumer goods.

When to Choose 5005 Aluminum Disc

Selecting the appropriate material for a specific application is crucial. Here are some scenarios in which choosing 5005 aluminum discs is particularly advantageous:

1. Corrosion Resistance

When your application is exposed to corrosive environments, such as marine or coastal settings, 5005 aluminum's exceptional corrosion resistance makes it an excellent choice.

2. Formability Requirements

If your project demands intricate shapes or deep drawing processes, 5005 aluminum's remarkable formability simplifies the manufacturing process.

3. Aesthetic Considerations

In applications where aesthetics are crucial, such as architectural elements or decorative items, 5005 aluminum's smooth and reflective surface finish allows for a visually pleasing result.

4. Thermal Efficiency

For applications requiring efficient heat transfer, such as heat exchangers or radiators, 5005 aluminum's superior thermal conductivity is a key advantage.

5. Light Weight

When weight reduction is essential, 5005 aluminum's lightweight nature aids in enhancing fuel efficiency in transportation applications.

Production and Processing Precautions

1. Annealing

Annealing is a heat treatment process that can be employed to improve the mechanical properties and formability of 5005 aluminum discs. Annealing can relieve internal stresses and enhance ductility, making the material easier to work with.

2. Cold Working

Cold working processes, such as rolling and cold extrusion, are commonly used to shape 5005 aluminum discs. These processes improve the material's mechanical properties and dimensional accuracy.

3. Surface Preparation

Proper surface preparation is crucial when using 5005 aluminum in applications that require coating or painting. Surface treatments like cleaning and etching should be performed to ensure adhesion and longevity of coatings.

4. Lubrication

When performing machining or forming operations on 5005 aluminum, the use of appropriate lubricants is essential to reduce friction and wear on tools and workpieces.

5. Proper Storage

To prevent contamination and damage, 5005 aluminum discs should be stored in a clean and dry environment. They should also be protected from exposure to corrosive substances.

Conclusion

The 5005 aluminum disc, with its exceptional properties and diverse range of applications, exemplifies the versatility and significance of aluminum alloys.

Its remarkable combination of corrosion resistance, formability, and weldability makes it a valuable material in various industries, including architecture, automotive, electrical, cookware, and more.

Furthermore, its environmentally friendly attributes, such as recyclability and resource efficiency, make it a sustainable material choice.

As industries continue to prioritize sustainability and efficiency, 5005 aluminum discs will continue to play a pivotal role in shaping the future of materials engineering and manufacturing.

Its multifaceted nature, combined with its ability to meet the demanding requirements of various sectors, ensures that the 5005 aluminum disc will remain a vital component in the modern world.