- Introduction to 3105 Aluminum Strip

- Customer Concerns about 3105 Aluminum Strip Quality

- 3105 Aluminum Strip Advantages

- 3105 Aluminum Strip Disadvantages

- 3105 Aluminum Strip Commonly Used Widths

- 3105 Aluminum Strip Surface Finish and Applications

- 3105 Aluminum Strip Chemical Composition

- 3105 Aluminum Strip Mechanical Properties

- 3105 Aluminum Strip Physical Properties

- 3105 Aluminum Strip Common Applications

- 3105 Aluminum Strip Common Temper and Specifications

- When to Choose 3105 Aluminum Strip

- Things to Note When Purchasing

- People Also Searched About 3105 Aluminum Strip

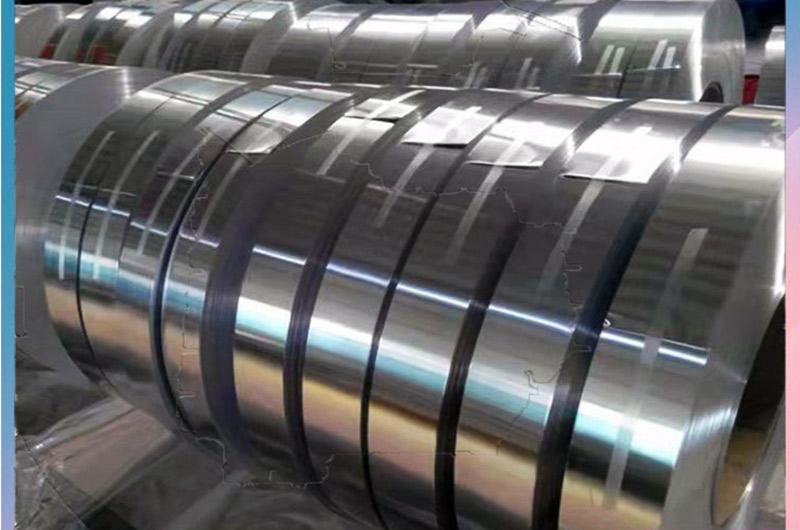

Introduction to 3105 Aluminum Strip

3105 aluminum strip is a non-heat-treatable alloy with excellent corrosion resistance, good formability, and high weldability. It belongs to the 3000 series of aluminum alloys, which are primarily composed of manganese as the major alloying element.

The addition of manganese enhances the strength and corrosion resistance of the alloy.

Customer Concerns about 3105 Aluminum Strip Quality

Customers often express concerns about the quality of 3105 aluminum strip, focusing on aspects such as:

1. Purity of the Alloy

Ensuring that the aluminum strip meets the specified purity standards.

2. Surface Finish

Customers are keen on a smooth and defect-free surface finish.

3. Mechanical Properties

Strength, ductility, and other mechanical properties are critical for various applications.

4. Corrosion Resistance

Given its common use, resistance to corrosion is a paramount concern.

5. Compliance with Specifications

Confirming that the aluminum strip meets industry and application-specific standards.

The 3105 aluminum strip produced by Haomei Aluminum is of high quality and meets standards, with stable performance, smooth surface, and competitive price.

3105 Aluminum Strip Advantages

- 1. Excellent Corrosion Resistance

- 2. Good Formability

- 3. High Weldability

3105 Aluminum Strip Disadvantages

- 1. Limited Heat-treatability

- 2. Moderate Strength

- 3. Not suitable for high-temperature applications

3105 Aluminum Strip Commonly Used Widths

3105 aluminum strips are available in various widths to cater to diverse applications. Commonly used widths include:

- 20mm 3105 aluminum strip

- 50mm 3105 aluminum strip

- 100mm 3105 aluminum strip

- 150mm 3105 aluminum strip

with custom sizes available based on specific requirements.

3105 Aluminum Strip Surface Finish and Applications

Different surface treatments enhance both the aesthetic appeal and performance of 3105 aluminum strips. Common surface finishes include:

3105 Mill Finish Aluminum Strip

Standard finish, suitable for general applications.

3105 Anodized Finish Aluminum Strip

Enhances corrosion resistance, often used in architectural applications.

3105 Painted Finish Aluminum Strip

Adds color and additional protection, suitable for decorative purposes.

3105 Aluminum Strip Chemical Composition

The chemical composition of 3105 aluminum strip typically includes:

- Aluminum (Al): 98.6%

- Manganese (Mn): 0.3% - 0.8%

- Magnesium (Mg): 0.2%

- Iron (Fe): 0.7%

- Copper (Cu): 0.2%

3105 Aluminum Strip Mechanical Properties

- Tensile Strength: 160 MPa (23, 000 psi)

- Yield Strength: 125 MPa (18, 000 psi)

- Elongation: 20%

3105 Aluminum Strip Physical Properties

- Density: 2.73 g/cm³

- Melting Point: 643°C (1, 189°F)

3105 Aluminum Strip Common Applications

3105 aluminum strips find applications in various industries, including:

- Construction: Used in roofing, facades, and decorative elements.

- Automotive: Trim components and interior applications.

- Electrical Industry: Busbars and conductive elements.

- Packaging: Seals and closures for containers.

- General Fabrication: Suitable for various fabrication processes.

3105 Aluminum Strip Common Temper and Specifications

- Temper H14: Strips are partially annealed, making them suitable for forming.

- Temper H16: Strips are substantially annealed, providing increased hardness.

Common specifications include ASTM B209 and EN 573.

When to Choose 3105 Aluminum Strip

Choose 3105 aluminum strip when:

- Corrosion Resistance is Crucial: Ideal for applications exposed to harsh environments.

- Formability is Needed: Suitable for processes like bending, drawing, and stamping.

- Weldability is a Priority: For applications requiring seamless welding.

Things to Note When Purchasing

- Quality Certification: Ensure the aluminum strip meets relevant industry standards.

- Surface Inspection: Check for any defects or inconsistencies in the surface finish.

- Dimensional Accuracy: Confirm that the strip meets the specified width and thickness requirements.

- Packaging: Proper packaging to prevent damage during transportation and storage.

People Also Searched About 3105 Aluminum Strip

- 3105 Aluminum Strip Properties

- Best Surface Finish for 3105 Strip

- Applications of 3105 Aluminum in Construction

- Welding Techniques for 3105 Strip

- Corrosion Resistance of 3105 Alloy

- Where to Buy High-Quality 3105 Aluminum Strip

- Comparisons with Other 3000 Series Alloys

- Common Thickness Options for 3105 Strip

In conclusion, 3105 aluminum strip offers a balance of corrosion resistance, formability, and weldability, making it a versatile choice for various applications.

Understanding its properties, applications, and considerations when purchasing ensures optimal use in specific industries and projects.