- What is a 3105 Aluminum Cap Closure?

- Frequently Asked Questions about the 3105 Aluminum Cap Closure

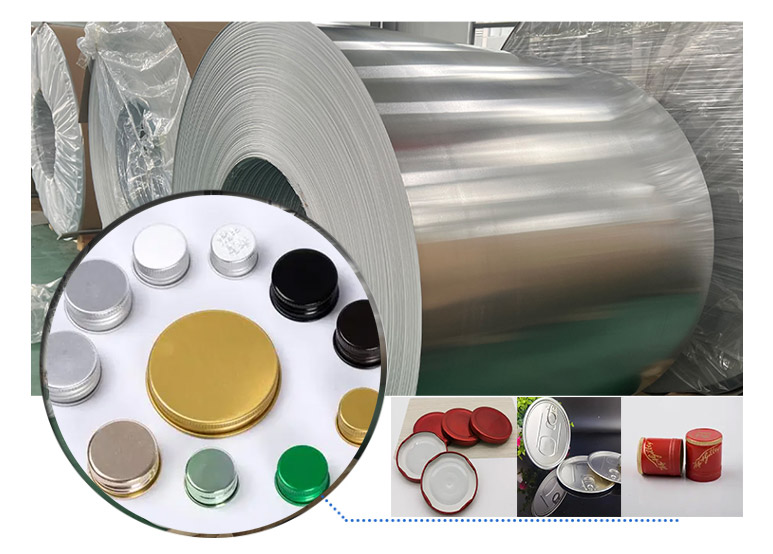

- Aluminum Cap Closure Surface Treatment

- 3105 Aluminum Cap Closure Specifications

- Haomei Aluminum Cap Closure Manufacturer

- 3105 Aluminum Cap Closure Classification

- 3105 Aluminum Bottle Cap Applications

- Printed Aluminum Screw Caps vs Aluminum Wine Screw Caps

- 3105 Aluminium Alloy Chemical Composition

What is a 3105 Aluminum Cap Closure?

The 3105 Aluminum Cap Closure refers to a type of closure cap made from 3105 aluminum alloy. It is commonly used in packaging applications to seal containers like bottles, jars, or tubes.

3105 aluminum is an aluminum alloy that is commonly used to make caps for bottles and containers. Caps made from this alloy are commonly used in the packaging industry for food and beverage products.

One of the main advantages of using 3105 aluminum for closures is its corrosion resistance, which makes it ideal for food and beverage packaging applications. This alloy is lightweight and strong, making it a popular choice for manufacturers looking to create durable yet lightweight closures.

In addition to corrosion resistance and strength, 3105 aluminum is easy to form and machine, making it a cost-effective choice for manufacturers. The alloy can be easily stamped, drawn or roll formed to create a variety of cap designs including screw caps, lug caps and crown caps.

Overall, 3105 aluminum lids are a popular choice for manufacturers in the food and beverage packaging industry due to their strength, corrosion resistance, and cost-effectiveness.

Frequently Asked Questions about the 3105 Aluminum Cap Closure

- 1. What are the Advantages of Using 3105 Aluminum for Cap Closures?

- 2. What Sizes are Available for the 3105 Aluminum Cap Closure?

- 3. What Types of Containers is the 3105 Aluminum Cap Closure Used for?

- 4. Is the 3105 Aluminum Cap Closure Suitable for Hot-fill Applications?

- 5. Can 3105 Aluminum Cap Closure be Used for Products with High Acidity or High Alkalinity?

- 6. What Liner Options are Available for the 3105 Aluminum Cap Closure?

- 7. Is the 3105 Aluminum Cap Closure Recyclable?

- 8. Where can I source 3105 Aluminum Cap Closures?

- 9. Can the 3105 Aluminum Cap Closure be Customized with Branding?

What are the Advantages of Using 3105 Aluminum for Cap Closures?

3105 aluminum alloy offers excellent corrosion resistance, making it suitable for use in packaging applications where the closure comes into contact with various substances. It is also easy to form, making it ideal for creating complex closure designs.

Is the 3105 Aluminum Cap Closure Suitable for Hot-fill Applications?

Yes, 3105 aluminum is known for its heat resistance, and it is often used in hot-fill applications for products like sauces and beverages.

Can 3105 Aluminum Cap Closure be used for Products with High Acidity or High Alkalinity?

While 3105 aluminum is generally corrosion-resistant, some products, especially those with high acidity or alkalinity, might require specific liner materials to prevent interaction between the product and the closure.

What Liner Options are Available for the 3105 Aluminum Cap Closure?

Liner options can include foam liners, pressure-sensitive liners, induction liners, and more, depending on the specific sealing and protection requirements of your product.

Is the 3105 Aluminum Cap Closure Recyclable?

Yes, aluminum is highly recyclable, and the 3105 aluminum cap closure can be recycled just like other aluminum products. Recycling aluminum requires significantly less energy compared to producing it from raw materials.

Can the 3105 Aluminum Cap Closure be Customized with Branding?

Many manufacturers offer options for customizing cap closures with branding, logos, or other designs. This can enhance your product's branding and overall aesthetic. Haomei Aluminum is a professional bottle cap material supplier with many years of rich production experience, competitive price and guaranteed quality.

Aluminum Cap Closure Surface Treatment

- Coating treatment : A layer of coating is formed on the surface of the aluminum bottle cap material by spraying, rolling and other methods to achieve the effect of protection and beautification. Commonly used coating materials include epoxy resin, polyester resin, polyurethane, etc.

- Oxidation treatment : Soak the surface of the aluminum bottle cap material in a solution containing an oxidant to oxidize the surface and form an oxide film to achieve the effect of protection and beautification.

- Sandblasting : Use high-pressure airflow to spray silica sand or other abrasives on the surface of aluminum bottle cap materials to remove surface burrs and blemishes to achieve a smooth and matte effect.

- Polishing treatment : Use machine equipment to mechanically polish the surface of the aluminum bottle cap material to remove surface burrs and blemishes to achieve a smooth and bright effect.

- Electroplating treatment : A protective metal coating is formed on the surface of the aluminum bottle cap material through electrochemical reaction to enhance its corrosion resistance and aesthetics. Commonly used electroplating methods include galvanizing, nickel plating, chrome plating, etc.

- DOS oil treatment : It is a surface treatment method that coats a layer of grease on the surface of the aluminum bottle cap material to achieve the effect of protection and beautification. Commonly used for rust and corrosion protection.

- Chromate treatment : It is a surface treatment method that forms a chemical conversion film by immersing the surface of the aluminum bottle cap material in a solution containing chromate. The film can enhance the corrosion resistance of aluminum bottle cap materials, reduce the surface friction coefficient, and improve the adhesion of the coating.

- Double-sided varnish/transparent lacquer treatment : It is a surface treatment method that coats a layer of varnish or clear varnish on the surface of aluminum materials to achieve the effect of protection and beautification. Commonly used to protect aluminum surfaces from the external environment and to increase their gloss and durability.

3105 Aluminum Cap Closure Specifications

The common specifications and sizes of 3105 aluminum bottle caps vary depending on the specific product used, the following are some common specifications and sizes :

- Height : ranging from 10mm - 30mm.

- Thickness : usually between 0.18mm - 0.25mm.

| Aluminum Cap Closure | Typical Diameter (mm) |

|---|---|

| 3105 Aluminum Cap Closure | 18 |

| 3105 Aluminum Cap Closure | 20 |

| 3105 Aluminum Cap Closure | 24 |

| 3105 Aluminum Cap Closure | 28 |

| 3105 Aluminum Cap Closure | 30 |

| 3105 Aluminum Cap Closure | 38 |

| 3105 Aluminum Cap Closure | 48 |

It should be noted that the specifications and dimensions of the 3105 aluminum cap bottle cap are not only affected by the requirements of the product to be contained, but also by the caliber, volume and other factors of the bottle. When selecting and designing aluminum caps, the actual situation of the product and the bottle should be fully considered to ensure the quality and use effect of the aluminum caps.

Haomei Aluminum Cap Closure Manufacturer

- Size and shape : Make custom aluminum closures to suit the caliber and shape of the customer's bottle or jar.

- Quality : To ensure that the quality of aluminum caps and seals meets customer requirements, corrosion resistance, mechanical strength, and sealing will be strictly tested.

- Surface treatment : According to customer requirements, aluminum cover seals with surface treatment will be selected to protect them from environmental elements.

- Packing method : Various packing methods, customers can choose the packing method suitable for them, such as carton, pallet, bag, etc.

3105 Aluminum Cap Closure Classification

3105 Aluminum Screw Cap Closure

Screw Cap Closure needs to be twisted to open. This type of cap seal has good sealing performance and is easy to use, while avoiding product leakage and oxidation.

- Diameter : 28mm

- Height : 18mm

- Application : For the sealing of bottled beverages or other liquid products, for example, like soda bottle caps, which need to be twisted open by turning clockwise or counterclockwise.

3105 Aluminum Ring Pull Closure

The Ring Pull Closure features a pull tab for easy access and quick opening without tools. In addition, the ring-pull cap seal can avoid direct contact between the cap seal and the product, maintaining the hygiene and quality of the product.

- Diameter : 26mm

- Height : 16mm

- Application : Usually used for the sealing of beer bottles or other alcohol bottled products, like beer bottle caps, and some gas drinks, there is a pull ring for easy opening.

3105 Aluminum Flip Top Closure

3105 Aluminum is easy to open and close, convenient to use, suitable for products that often need to be used frequently. Additionally, the flip-top closure maintains product freshness and hygiene.

- Diameter : 63mm

- Height : 22mm

- Application : Usually used on containers like jam jars or medicine bottles, sealing jam jars, honey bottles, medicine bottles and other products.

3105 Aluminum Push-Pull Closure

Push-Pull Closures require a push or pull to open, this type of closure maintains product freshness and hygiene while being easy to use. Additionally, the push-pull lid seal prevents product leakage and oxidation.

- Diameter : 50mm

- Height : 12mm

- Application : Like a gum or biscuit box, it needs to be pushed or pulled to open the lid seal.

The state of 3105 aluminum alloy is usually hardened state such as H14, H16, H18, etc., to ensure that the cover seal has sufficient strength and corrosion resistance. For the specification of the cap seal, it needs to be determined according to the size of the product container and the use requirements, such as the diameter and height of the cap seal.

3105 Aluminum Bottle Cap Applications

3105 aluminum cap closures have a wide range of application prospects and can be used for a variety of bottled and closed products in multiple industries.

| Field | Instance |

|---|---|

| Food, Beverages | Bottled water, soft drinks, juices, beer, alcoholic beverages, salad dressings, sauces |

| Medical | medicine bottle, oral liquid bottle, eye drop bottle, infusion bottle |

| Cosmetics | Perfume, lotion, shampoo, body wash |

It is important to choose the appropriate type of aluminum cover according to the characteristics of the specific product and the usage scenario to achieve the best sealing effect and user experience.

Printed Aluminum Screw Caps vs Aluminum Wine Screw Caps

3105 Printed Aluminum Sheet for Screw Caps

Printed Aluminum Sheet for Screw Caps is a special model that coats a layer of ink or paint on the 3105 aluminum alloy sheet. The coating serves two purposes : it enhances the appearance of the nut and protects the aluminum surface from oxidation and other forms of corrosion.

The application of Printed Aluminum Sheet for Screw Cap is not only for wine bottle caps, but also for others.

- Bottled Wine : Aluminum screw caps are standard for many bottled wines. 3105 Printed Aluminum Sheet for Screw Caps can be printed with the winery's logo, graphics and text to make its brand more prominent.

- Beverage Bottles : Aluminum screw caps are also widely used in bottle caps for bottled water, carbonated drinks and other beverages. The name and pattern of the beverage brand can be printed to enhance brand recognition.

- Cosmetic bottles : Aluminum screw caps are also used to make cosmetic bottle caps. Can be printed with cosmetic brand names, logos and other graphics.

- Food containers : Aluminum threaded caps are also used in some food containers, such as the sealing of jam bottles and candied fruit bottles. 3105 DC Printed Aluminum Sheet for Screw Caps can be printed with food brand name and pattern to enhance brand image.

3105 Aluminum Wine Closure Sheet for Screw Caps

3105 Aluminum Wine Bottle Closure Plate for Screw Caps is another form of 3105 aluminum alloy sheet designed specifically for use with wine bottle caps. It is characterized by its excellent deep-drawing properties, which allow it to be easily formed into desired shapes without cracking or tearing.

- Wine bottle : 3105 Aluminum Wine Closure Sheet for Screw Caps is mainly used to make wine bottle caps. This aluminum alloy plate has excellent sealing performance, which can protect the quality and taste of wine.

- Other wine bottles : In addition to wine bottles, 3105 Aluminum Wine Closure Sheet for Screw Caps can also be used to make caps for other wine bottles, such as beer bottles and whiskey bottles.

- Food containers : 3105 Aluminum Wine Closure Sheet for Screw Caps can also be used to make some food containers, such as the closure of jam bottles and seasoning bottles. This aluminum alloy plate has excellent sealing performance, which can protect the freshness and taste of food.

3105 Aluminium Alloy Chemical Composition

Please keep in mind that these values are approximate ranges and can vary based on specific alloy batches and manufacturer specifications.

| Element | Chemical Composition Range (% by weight) |

|---|---|

| Aluminum (Al) | 96.8% - 98.5% |

| Magnesium (Mg) | 0.3% - 0.8% |

| Manganese (Mn) | 0.3% - 0.8% |

| Iron (Fe) | 0.7% (maximum) |