- 3104 Aluminum Plate Features

- 3104 Aluminum Sheet Specifications

- Advantages of 3104 Aluminum Plate

- 3104 Aluminum Plate Weldability

- Typical 3104 Aluminum Plate

- 3104 Aluminum Properties

- What is 3104 Aluminum Used for?

- Aluminum 3104 Chemical Composition

- Chemical Composition of 3104 Aluminium Sheet

- Mechanical Properties of 3104 Aluminum Sheet

The performance of 3104 aluminum plate is similar to that of 3004 aluminum plate. 3104 aluminum plate has excellent deep drawing performance, high tensile strength, good processing performance, and the elongation can reach up to 20%.

- Good deep drawing performance: 3104 aluminum alloy is suitable for the stamping of beverage cans.

- Excellent anodizing effect on the surface: Make it a color-coated aluminum substrate.

3104 aluminum plate has low density, high strength, easy forming, and recyclable. It is often used in aluminum shutters, lamp head materials, light aluminum, and can materials.

3104 h19 can lid materials, lamp head materials, corrugated boards, roof panels, color-coated aluminum, shutters, oxide materials, mobile phone battery cases, automobile fuel tanks, etc.

3104 Aluminum Plate Features

Because 3104 aluminum has appropriate elongation, good corrosion resistance and excellent processing performance, we can smelt and process it into alloy states of different hardness according to different application requirements.

- 1. Comfortable, light, durable, economical and environmentally friendly.

- 2. It has good deep drawing performance and tensile strength, and the elongation can reach 20%.

- 3. Good anti-corrosion and processing performance.

3104 Aluminum Sheet Specifications

- Thickness : 0.2-6.35mm (0.008-0.25inch)

- Width : 100-2600 mm (3.9-102.4 inches)

- Length : as per customer requirement

- Temper : H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38

- Surface finish : mill finish, bright finish, anodized, coated

- Standard : ASTM B209

- Equivalent standards : EN 485-2, AMS 4004, AMS-QQ-A-250/8, DIN AlMn1Mg1

Advantages of 3104 Aluminum Plate

- 1. Good stamping performance. 3104 aluminum alloy has good ductility, cutting processability and formability, and can adapt to the highest speed that can be achieved by most machine tools for milling, boring, planing and other mechanical processing.

- 2. Strong corrosion resistance. 3104 aluminum plate can well resist the corrosion of carbonated beverages such as steam acid and alkali.

- 3. Good anodizing effect. The surface of 3104 aluminum plate treated with anodizing has better corrosion resistance and can present rich and colorful colors.

3104 Aluminum Plate Weldability

Although 3104 aluminum alloy plate has good processing performance, its welding performance is relatively general compared with some other aluminum alloy materials. Special technical measures need to be taken during the welding process to avoid defects such as welding cracks.

Typical 3104 Aluminum Plate

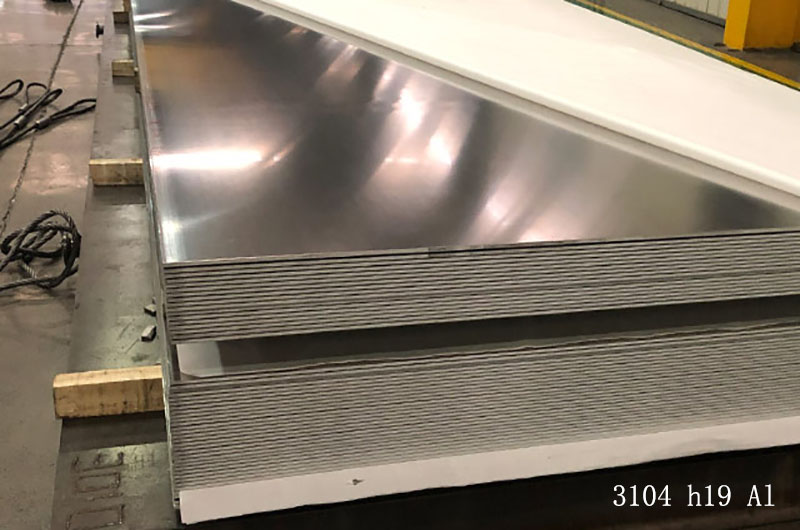

3104 H19 Aluminum Plate

H19 is a very high strength temper achieved through a very extensive strain hardening process.

- Properties : 3104 h19 has higher strength but lower ductility than H18, higher strength than H18 but lower formability.

- Application : Suitable for applications requiring maximum strength and minimum formability. 3104 H19 is also used in beverage cans along with 5182 aluminum alloy.

3104, 5182 provide the necessary strength and formability for the can body and can end respectively. Beverage cans made with 3104-H19 and 5182 are lightweight, durable, and corrosion-resistant, making them ideal for carbonated and non-carbonated beverage packaging.

3104 O Aluminum Plate

3104 O is the softest temper and is achieved by heating the aluminum to a specific temperature and then cooling it slowly.

Properties : 3104 o has relatively low strength but high ductility,

Application : Suitable for applications requiring good formability, complex shapes, such as cans, lids, bottle caps for food and beverage packaging.

3104 H12 Aluminum Plate

H12 is a strain hardening temper achieved by a partial annealing process.

- Properties : 3104 h12 has higher strength and lower ductility than O temper, this temper has higher strength than O temper, but still has some formability.

- Application : Ideal for applications that require some formability but also some strength, such as HVAC components, heat exchangers, and lighting reflectors.

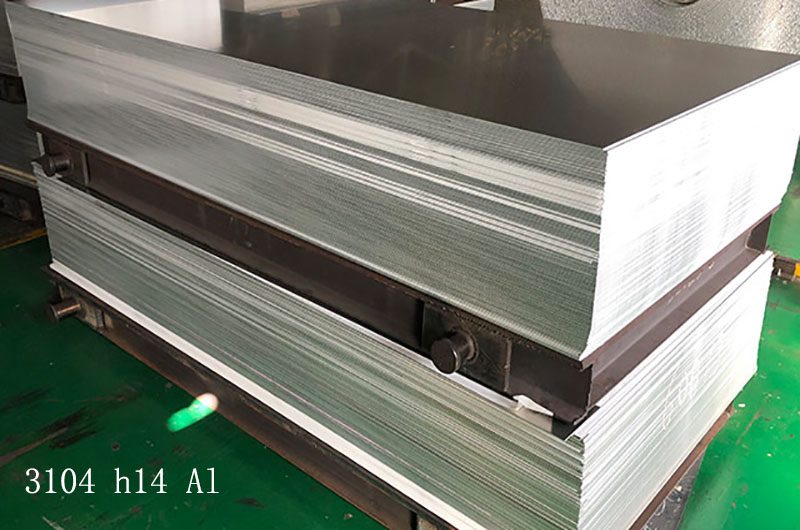

3104 H14 Aluminum Plate

3104 H14 is a more severe strain hardening temper than H12.

- Properties : With higher strength and lower ductility, this tempered state has higher strength and lower formability than H12.

- Application : For applications requiring good strength and moderate formability, such as automotive body panels, fuel tanks, and chemical processing equipment.

3104 H16 Aluminum Plate

H16 This temper is similar to H14 and less ductile.

- Properties : This tempered condition is stronger and less formable than H14.

- Application : It is suitable for applications requiring high strength and minimal formability, such as truck trailer sidewalls, boat hulls and aircraft components.

3104 H18 Aluminum Plate

H18 is the hardest temper of 3104 aluminum, achieved through a more extensive strain hardening process.

- Properties : It has very high strength but very low ductility, with the highest strength and lowest formability in the tempered state of 3104 aluminum sheet.

- Application : It is suitable for applications requiring maximum strength and minimum formability, such as missile components, armor plates and structural components in high stress environments.

3104 h32 Aluminum Plate

H32 - This is the strain hardened and stable tempered condition achieved by low temperature heat treatment after the initial strain hardening process. With good strength and excellent formability, it is suitable for applications requiring both strength and formability.

H32 : This tempered state has good strength and excellent formability due to low temperature heat treatment. It is suitable for applications where both strength and formability are required, such as sheet metal fabrication, automotive body panels and signage.

3104 Aluminum Properties

What is 3104 Aluminum Used for?

3104 Aluminum Sheet Coil for Beverage Can

3104 aluminum plate is commonly used to make beverage cans, and there is also 5182 aluminum alloy. The combination of these two alloys provides the necessary strength and formability for the can body and end respectively.

- 3104-H19 aluminum alloy for beverage can body

- 5182 aluminum alloy to make can lids.

The combination of these two alloys provides a lightweight, durable and corrosion-resistant can suitable for both carbonated and still beverages.

3104 Automotive Body Aluminum Sheet Plate

3104 aluminum sheet is used in the manufacture of automotive body panels due to its good formability, corrosion resistance and paintability.

- Temper : H14, H16

- Application : For the manufacture of body panels such as hoods, fenders and doors.

Click to learn more aboutAutomotive Aluminum Plate

3104 Aluminum Sign

The high reflectivity and formability of 3104 aluminum sheet make it an ideal material for signage used in a variety of applications.

- Temper : H19, H14

- Application : Used in the manufacture of traffic signs, billboards and architectural signs.

Click to learn more aboutTraffic Aluminum

3104 Cookware Aluminum Sheet or Plate

3104 aluminum sheet is used in the manufacture of kitchenware such as cookware and utensils due to its corrosion resistance and ability to be formed into various shapes.

- Temper : H14, H16

- Application : used to make pots, bakeware, etc.

Click to learn more aboutCookware Aluminum

3104 Aluminum Sheet Coil for Lighting Reflector

The high reflectivity of 3104 aluminum sheet makes it an ideal material for lighting reflectors used in various applications.

- Temper : H19, H14

- Application : Reflectors for automotive headlamps, street lamps and interior lighting.

Click to learn more aboutLighting Aluminum

3104 Aluminum Fin Stock Material

3104 aluminum plate has good thermal conductivity and corrosion resistance. It is an ideal material for heat exchanger components such as fin material, evaporator fin, and pipe fittings.

- Temper : O , H14

- Application : Used in heat exchangers for automotive and HVAC applications.

HVAC Components Air Conditioning Fins Coils

3104 aluminum sheet is often used in HVAC components due to its good thermal conductivity and corrosion resistance.

- Temper : H14, H16

- Application : 3104 aluminum alloy is used in the manufacture of air conditioning fins and coils, etc.

Chemical Processing Equipment

3104 aluminum alloy sheet or plate is used to manufacture tanks and piping for chemical processing applications due to its corrosion resistance.

3104 aluminum alloy is generally available in sheet or sheet form in the O or H111 temper.

Aluminum 3104 Chemical Composition

| Elements | Si | Fe | Cu | Mn | Mg | Zn | Others | Al |

| Content | 0.6 | 0.8 | 0.05~0.25 | 0.8~1.4 | 0.8~1.3 | 0.25 | 0.05 | Remain |

Chemical Composition of 3104 Aluminium Sheet

| Elements | Si | Fe | Cu | Mn | Mg | Zn | Others | Al |

| Content | 0.6 | 0.8 | 0.05~0.25 | 0.8~1.4 | 0.8~1.3 | 0.25 | 0.05 | Remain |

Mechanical Properties of 3104 Aluminum Sheet

| Tensile strength σb (MPa) | Yield strengt σ0.2 (MPa) | Elongation δ10 (%) |

| ≥275 | ≥70 | 20 |

| Al Temper | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) |

| 3104 H12 | 110 | 85 | 15 |

| 3104 H14 | 145 | 125 | 7 |

| 3104 H16 | 170 | 150 | 5 |

| 3104 H18 | 195 | 175 | 4 |

| 3104 H22 | 150 | 110 | 12 |

| 3104 H24 | 175 | 130 | 10 |

| 3104 H26 | 195 | 145 | 8 |

| 3104 H28 | 215 | 170 | 6 |

| 3104 H32 | 215 | 160 | 7 |

| 3104 H34 | 235 | 185 | 5 |