- Introduction of 3005 Aluminum Plate Sheet

- Properties of 3005 Aluminum Plate Sheet

- Advantages of 3005 Aluminum Plate Sheet

- Disadvantages of 3005 Aluminum Plate Sheet

- Applications of 3005 Aluminum Plate Sheet

- Manufacturing Process of 3005 Aluminum Plate Sheet

- Conclusion

Introduction of 3005 Aluminum Plate Sheet

Among the many aluminum plates available, the 3005 aluminum plate stands out as a popular choice for a wide range of applications. In this comprehensive guide, we will delve into the world of 3005 aluminum plate sheets, exploring their properties, applications, and the manufacturing process in detail.

Properties of 3005 Aluminum Plate Sheet

3005 Aluminum Plate Chemical Composition

3005 aluminum plate belongs to the 3xxx series of aluminum plates, which are known for their excellent corrosion resistance. The chemical composition of 3005 aluminum plate typically includes:

| Chhemical Element | Content (%) |

| Aluminum, Al | 95.7 - 98.8 |

| Manganese, Mn | 1- 1.5 |

| Iron, Fe | ≤ 0.70 |

| Silicon, Si | ≤ 0.60 |

| Copper, Cu | ≤ 0.30 |

| Zinc, Zn | ≤ 0.25 |

| Magnesium, Mg | 0.20 - 0.60 |

| Chromium, Cr | ≤ 0.10 |

| Titanium, Ti | ≤ 0.10 |

| Other (each) | ≤ 0.050 |

| Other (total) | ≤ 0.15 |

Mechanical Properties of 3005 Aluminum Plate

3005 aluminum plate sheets possess a set of mechanical properties that make them suitable for various applications. Key mechanical properties include:

| Alloy-Temper |

Tensile Strength (ksi) |

Yield Strength (ksi) |

Elongation (%) |

| 3005-O | 20 | 8 | 22 |

| 3005-H14 | 29 | 28 | 4 |

| 3005-H18 | 37 | 36 | 2 |

3005 Aluminum Plate Corrosion Resistance

One of the outstanding features of 3005 aluminum palte is its exceptional corrosion resistance. 3105 alloy offers excellent resistance to both general atmospheric corrosion and saltwater corrosion. This makes it ideal for applications in coastal environments, automotive components, and outdoor structures.

Formability

3005 aluminum is highly formable, allowing it to be easily shaped, bent, and fabricated. This property makes it suitable for manufacturing processes such as roll forming, stamping, and deep drawing, which are essential in industries like automotive, building, and packaging.

Weldability

The weldability of 3005 aluminum is another valuable characteristic. It can be readily welded using various methods such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and resistance welding. This quality makes it a preferred choice for the construction of lightweight structures that require welding.

Surface Finish

3005 aluminum plate sheets can be finished in a variety of ways, including anodizing, painting, and powder coating. The smooth surface allows for high-quality finishes and enhances their aesthetic appeal, making them suitable for architectural and decorative applications.

Advantages of 3005 Aluminum Plate Sheet

- Corrosion Resistance: 3005 aluminum offers exceptional corrosion resistance, making it ideal for outdoor and marine applications.

- Lightweight: Aluminum is naturally lightweight, and 3005 aluminum retains this property, contributing to fuel efficiency in transportation and ease of handling in various applications.

- Formability: The alloy is highly formable, allowing for the creation of complex shapes and profiles.

- Weldability: 3005 aluminum can be easily welded, providing flexibility in manufacturing processes.

- Recyclability: Aluminum is highly recyclable, making it an eco-friendly material choice.

- Good Electrical Conductivity: The alloy's electrical conductivity is suitable for applications in the electronics industry.

Disadvantages of 3005 Aluminum Plate Sheet

- Lower Strength: While 3005 aluminum has adequate mechanical properties for many applications, it may not be suitable for heavy structural uses that demand higher strength.

- Cost: Aluminum alloys can be more expensive than some other materials, such as steel.

Applications of 3005 Aluminum Plate Sheet

| Industry | Application | Why Choose 3005 Aluminum Plate |

| Automotive | Body panels, components | Due to its light weight and corrosion resistance, 3005 aluminum plate reduces vehicle weight, improves fuel efficiency, and increases durability. |

| Food and Beverage Packaging | Can lids, can bodies | 3005 aluminum plate offers corrosion resistance, ensuring the safety and integrity of food and beverage products. |

| Building and Construction | Roofing, wall panels, cladding systems | Its excellent corrosion resistance makes 3005 aluminum plate ideal for exterior cladding systems, maintaining appearance and structural integrity over time. |

| Marine | Hulls, ship components | With outstanding saltwater corrosion resistance and light weight, 3005 aluminum plate extends the lifespan of marine hulls and components. |

| Electronics | Electronic device enclosures | The good conductivity, light weight, and corrosion resistance of 3005 aluminum plate make it ideal for electronic device enclosures. |

| Solar Energy | Solar panel frames, mounting systems | Its light weight helps reduce the overall weight of solar installations while providing durability and stability. |

| Decorative and Architectural | Building facades, signage, interior design | The smooth surface and ability to hold paint and coatings make 3005 aluminum plate suitable for high-quality decorative and architectural applications. |

| Household Appliances | Components and housings | 3005 aluminum plate enhances the durability and aesthetics of home appliances such as refrigerators, ovens, and air conditioners. |

3005 Automotive Aluminum Plate

3005 aluminum plate is extensively used in the automotive industry due to its combination of lightweight and corrosion resistance. 3005 automotive aluminum plate is commonly employed for manufacturing automotive body panels, such as hoods, trunk lids, and doors. The alloy's formability and weldability also make it suitable for producing intricate automotive components.

3005 Aluminum Plate for Food and Beverage Packaging

The aluminum alloy 3005 is widely used in the packaging industry for making beverage can lids and food can bodies. Its ability to resist corrosion and its formability are crucial in ensuring the safety and integrity of the packaged products.

3005 Aluminum Plate for Building and Construction

In the building and construction sector, 3005 aluminum plate sheets find applications in roofing, siding, and other exterior cladding systems. Their corrosion resistance ensures that these materials maintain their appearance and structural integrity in harsh outdoor conditions. Additionally, 3005 aluminum can be formed into various profiles for architectural elements.

3005 Marine Aluminum

Because of its exceptional resistance to saltwater corrosion, 3005 aluminum is employed in the marine industry for boat hulls, shipbuilding components, and various marine equipment. Its lightweight nature contributes to better fuel efficiency and overall performance of vessels.

3005 Aluminum Plate for Electronics

In the electronics industry, 3005 aluminum plate is used in the production of casings for electronic devices. The alloy's good electrical conductivity, combined with its lightweight properties and corrosion resistance, makes it a suitable choice for this application.

3005 Aluminum for Solar Energy

As the solar energy industry continues to grow, 3005 aluminum is increasingly used in the manufacturing of solar panel frames and mounting systems. Its lightweight nature reduces the overall weight of solar installations, making them easier to handle and transport.

3005 Aluminum for Decorative and Architectural Applications

3005 aluminum plate sheets are used for decorative and architectural purposes, such as building facades, signage, and interior design elements. The smooth surface finish and the ability to hold paint and coatings make it an attractive choice for these applications.

3005 Aluminum for Household Appliances

Household appliances like refrigerators, ovens, and air conditioners often use 3005 aluminum for various components and housing due to its corrosion resistance and formability. It contributes to the durability and appearance of these appliances.

Manufacturing Process of 3005 Aluminum Plate Sheet

1. Aluminum Ingot Casting

The production of 3005 aluminum plate sheets typically begins with the casting of aluminum ingots. This involves melting aluminum alloy containing the specified proportions of elements, including manganese, magnesium, and others, in a furnace. Once the molten metal is properly alloyed, it is poured into ingot molds to solidify.

2. Hot Rolling

The cast ingots are then hot-rolled into semi-finished products, which are typically in the form of thick aluminum plates. Hot rolling is a process that involves passing the aluminum ingots through a series of rolling mills. This process reduces the thickness of the aluminum while increasing its length and width.

3. Cold Rolling

After hot rolling, the aluminum plates undergo cold rolling, a process that further refines the material. Cold rolling reduces the thickness of the plates to their final dimensions. This process also improves the surface finish and mechanical properties of the material.

4. Annealing

To relieve any residual stresses from the rolling processes and enhance the material's formability, the aluminum sheets are subjected to an annealing process. Annealing involves heating the aluminum to a specific temperature and then gradually cooling it. This process improves the overall workability of the material.

5. Slitting and Cutting

The rolled and annealed aluminum sheets are then slit and cut to the desired size and shape. This step involves using specialized machinery to cut the sheets into the required dimensions, which may vary depending on the intended application.

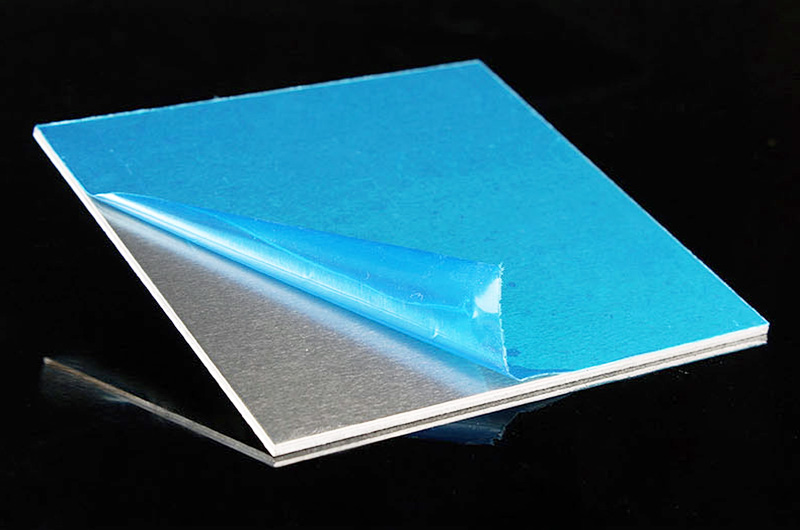

6. Surface Treatment

Depending on the application, the 3005 aluminum plate sheets may undergo various surface treatments. This can include anodizing, which enhances the corrosion resistance and provides an aesthetically pleasing finish. Alternatively, the surface may be prepared for painting or powder coating to suit specific requirements.

7. Quality Control

Quality control is a critical step in the manufacturing process. Various tests, including mechanical testing, chemical analysis, and surface quality checks, are conducted to ensure that the 3005 aluminum plate sheets meet the specified standards and requirements.

8. Packaging and Shipping

The final products are packaged for protection during transportation and storage. The 3005 aluminum plates are usually bundled or placed on pallets to prevent damage. They are then shipped to customers or distributors for further use.

Conclusion

3005 aluminum plate sheets are a remarkable choice for a wide range of applications, thanks to their outstanding combination of properties.

With exceptional corrosion resistance, lightweight nature, and excellent formability, 3105 aluminum sheets find applications in the automotive industry, building and construction, packaging, marine, electronics, solar energy, and more.

3105 aluminum plate the manufacturing process involves casting, hot rolling, cold rolling, annealing, and various surface treatments, resulting in high-quality, reliable products.

While 3005 aluminum may not be suitable for applications requiring high strength, its advantages make it a popular material choice in many industries, contributing to improved product performance and longevity.