- Advantages and Disadvantages of 3004 Aluminum Plate

- 3004 Aluminum Plate Specifications

- 3004 Aluminum Plate Typical Sizes

- Typical 3004 Aluminum Plate

- 3004 Aluminum Plate Applications

- 3004 Aluminum Plate Properties

- Other Properties for 3004 Aluminum Plate

- 3004 Aluminum Plate Composition

- What is Equivalent to 3004 Aluminum?

- What is the Difference between 3003 and 3004 Aluminum Plate?

- What is Wrought Aluminum Manganese Alloy 3004?

3004 aluminum alloy typically contains about 1% manganese and 1% magnesium, which contribute to its strength and corrosion resistance. It is commonly used in the manufacture of automotive parts, beverage cans and other sheet metal applications.

3004 aluminum is stronger than 3003 alloy, but has lower ductility. The composition of 3004 is similar to that of 3003 aluminum plate, and it has many of the same applications as 3003 aluminum plate.

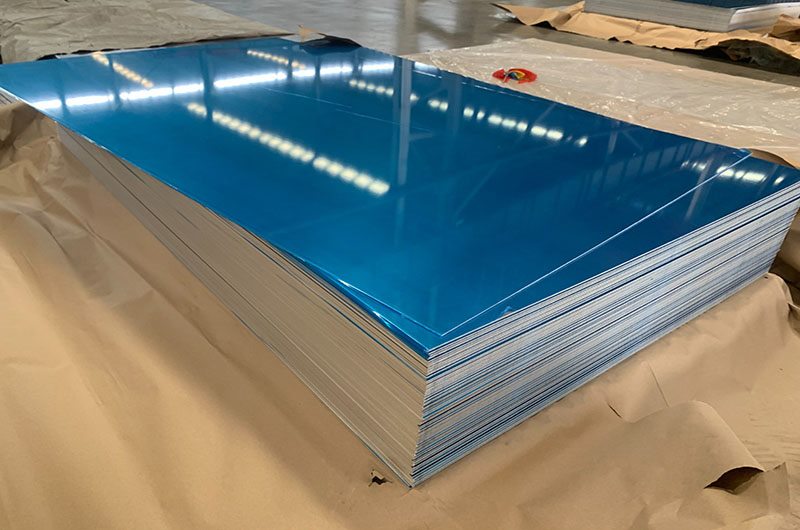

Like other aluminum alloys, 3004 aluminum sheet is available in a variety of sizes, thicknesses and finishes to meet the needs of different industries and applications. It can be coated, painted or anodized to provide additional protection against corrosion and improve its appearance.

Advantages and Disadvantages of 3004 Aluminum Plate

3004 aluminum has high strength, good formability, good processability, excellent corrosion resistance and drawing characteristics.

3004 aluminum plate is usually rolled and extruded, but is generally not heat treatable, not forged, and not used for casting.

The mechanical properties of 3004 aluminum plate can be improved through cold working.

3004 Aluminum Plate Specifications

- Temper : H19, H14, H16, H18, H22, H24, H26, O, etc.

- Thickness : 0.2mm - 6mm

- Width : 500mm - 2800mm

- Length : 1000mm - 12000mm

- Surface treatment : Mill Finish, Polished, Brushed, Embossed, Perforated, Anodizing, Powder coating, etc.

- Standards : National standards for ASTM B209, 3004 aluminum sheets vary by country or region.

- Technical : Hot rolled ( DC ) or Cold rolling ( CC )

3004 Aluminum Plate Typical Sizes

- 4x8 3004 Aluminum Plate

- 4x10 3004 Aluminum Plate

- 48x96 3004 Aluminum Plate

- 1000 x 2000mm 3004 Aluminum Plate

- 1250mm x 2500mm 3004 Aluminum Plate

Typical 3004 Aluminum Plate

3004 H19 Aluminum Plate

3004-H19 Aluminum This is a strain hardened and partially annealed aluminum sheet that is stronger than the annealed (O) condition.

- Advantages : high strength, good formability, excellent corrosion resistance.

- Applications : Suitable for applications requiring good strength and formability, beverage cans, food containers, cosmetic packaging and similar products.

3004 H18 Aluminum Plate

3004 H18 Aluminum Plate : This is a strain hardened and fully annealed aluminum sheet that is stronger than the annealed (O) condition and the H19 temper.

- Advantages : high strength, excellent corrosion resistance, good formability.

- Applications : Suitable for applications requiring high strength and excellent corrosion resistance, such as building facades, storage tank transportation, marine and industrial application buildings.

3004 O Aluminum Plate

3004 O aluminum plate : This is the annealed state of 3004 aluminum plate, which has the lowest strength but the highest formability.

- Advantages : excellent formability and good corrosion resistance.

- Field of application : Suitable for applications requiring good formability, such as sheet metal processing of cans, containers and other products requiring good formability.

3004 Aluminum Plate Applications

3004 aluminum plates are mainly used in chemical product production and storage devices, thin plate processing parts, building materials, building baffles, cable ducts, sewers, various lighting parts, beverage cans, corrugated boards, building materials, colored aluminum plates, and lamp holders.

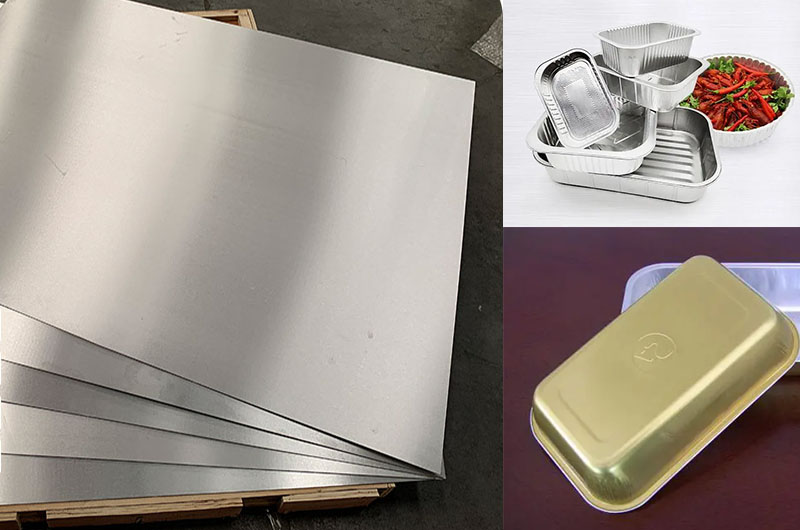

3004 Aluminum for Can Packaging

3004 aluminum can be used for aluminum beverage packaging, aluminum bottles, aluminum cans, coffee cups, container cups, etc. after punching.

There are many canned drinks that are commonly seen in life, such as Coca-Cola, Jiaduobao, etc. These canned drinks have a common feature, they are all in cans, and cans are processed and produced with aluminum alloy materials.

The aluminum alloy pop can ring, the aluminum alloy pop can lid and the can body are all made of different alloy aluminum plates.

- 5182 aluminum plate is mostly used for pull rings of cans

- The can lid is made of 3004 aluminum plate

Advantages of 3004 Aluminum for can packaging

- High strength

- High extension

- Easy to form

- High recyclability and infinite recyclability, reducing its carbon footprint

3004 Coated Aluminum Plate

3004 aluminum plate, also known as aluminum-magnesium panel in the construction industry, is widely used in the exterior decoration of factory roof buildings. 3004 coated board is stronger than 1060 coated board and 3003 coated board, and is more suitable for areas with a lot of bad weather.

| Alloy | 3004 | 1060/3003 |

|---|---|---|

| Advantages | High strength, strong corrosion resistance | Obvious price advantage |

| Disadvantages | Expensive | Low intensity |

As a roof panel, 3004 aluminum plate is a cost-effective panel material and exterior wall material, and is generally recognized as a roof and exterior wall material with an architectural design service life of more than 50 years.

Advantage :

- Moderate structural strength, weather resistance, stain resistance

- Easy to bend, weld, etc.

If you want to deal with the architectural design of the humid climate relative to the conventional, you can choose the more corrosion-resistant 5052 aluminum plate for processing.

3004 Aluminum for Lunch Box

Application in aluminum foil lunch boxes Because the strength of 3004 is higher than that of 8011 alloy and 3003 alloy, it has completely replaced 3003 alloy and 8011 alloy in domestic single-cavity lunch boxes. For European and American regions with strong environmental awareness, our company's 3004 aluminum foil lunch Box machine materials are recognized by most customers.

| Alloy | 3004 | 1060/3003 |

|---|---|---|

| Advantages | High strength, high cost performance | Can do multi-cavity and wrinkle-free lunch boxes |

| Disadvantages | Can only be used as a single-chamber lunch box | Expensive |

3004 Aluminum for Radiator

The radiator is a device for dissipating heat from the electronic parts that are prone to heat in electrical appliances. Reasonable selection of high-quality radiator components can better extend the service life of power devices.

3004 aluminum plate is currently the most widely used radiator material in the market, and its advantages are as follows :

- High stamping elongation

- Good strength

- Good color printing performance

- Good formability and solubility

- Good corrosion resistance

- Good coloring

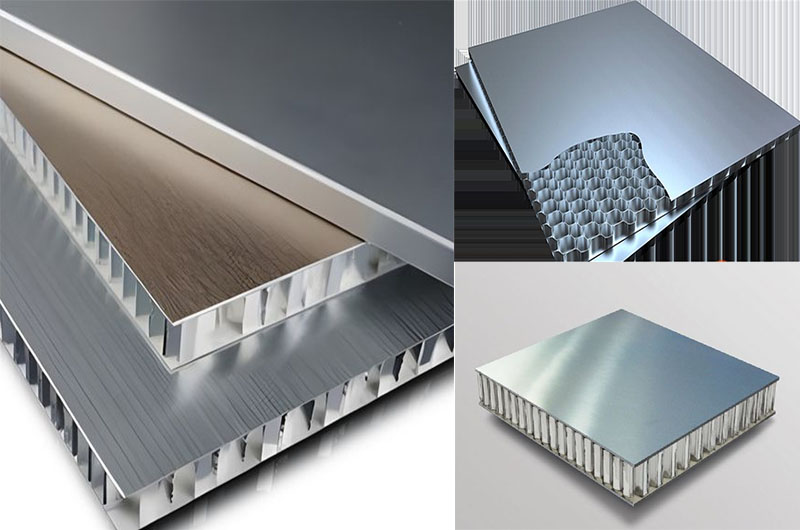

3004 H18 Honeycomb Aluminum Plate

In the application of aluminum honeycomb core, the higher the strength requirement of the honeycomb core, the better. The 3004 honeycomb core aluminum foil produced by our company has replaced the traditional 3003 aluminum foil, and the 3004 honeycomb core aluminum foil has a very high cost performance, and is also recognized by most customers.

| Application | Alloy | Temper | Width |

|---|---|---|---|

|

Honeycomb panel |

3004 | H18 | 0.1-2 |

| 1060 |

3004 Aluminum Plate Properties

| Property | Value |

|---|---|

| Density | 2.7 g/cm3 |

| Tensile strength | 180-220 MPa |

| Yield strength | 80-110 MPa |

| Modulus of elasticity | 69 GPa |

| Poisson's ratio | 0.33 |

| Elongation at break | 10-20% |

| Hardness, Brinell | 47-60 |

| Alloy-Temper | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) |

|---|---|---|---|

| 3004-O | 26 | 10 | 19 |

| 3004-H34 | 39 | 29 | 5 |

| 3004-H38 | 41 | 36 | 4 |

| Temper | Specified Thickness(in) | Tensile Strength - KSI | Elongationin 2 inches % | |

| Ultimate | ||||

| Min | Max | |||

| 3004 H12 | 0.008 - 0.020 | 27.6 | 34.8 | 2 |

| 3004 H12 | 0.020 - 0.059 | 27.6 | 34.8 | 3 |

| 3004 H12 | 0.059 - 0.118 | 27.6 | 34.8 | 4 |

| 3004 H12 | 0.118 - 0.236 | 27.6 | 34.8 | 5 |

| 3004 H12 | 0.236 - 0.394 | 27.6 | 34.8 | - |

| 3004 H14 | 0.008 - 0.020 | 31.9 | 38.4 | 1 |

| 3004 H14 | 0.020 - 0.059 | 31.9 | 38.4 | 2 |

| 3004 H14 | 0.059 - 0.118 | 31.9 | 38.4 | 2 |

| 3004 H14 | 0.118 - 0.250 | 31.9 | 38.4 | 3 |

| 3004 H16 | 0.008 - 0.020 | 34.8 | 41.3 | 1 |

| 3004 H16 | 0.020 - 0.059 | 34.8 | 41.3 | 1 |

| 3004 H16 | 0.059 - 0.118 | 34.8 | 41.3 | 2 |

| 3004 H16 | 0.118 - 0.250 | 34.8 | 41.3 | 2 |

| 3004 H18 | 0.008 - 0.020 | 37.7 | - | 1 |

| 3004 H18 | 0.020 - 0.059 | 37.7 | - | 1 |

| 3004 H18 | 0.059 - 0.118 | 37.7 | - | - |

| 3004 H18 | 0.118 - 0.250 | 37.7 | - | - |

| 3004 H19 | 0.008 - 0.020 | 39.2 | - | 1 |

| 3004 H19 | 0.020 - 0.059 | 39.2 | - | 1 |

| 3004 H19 | 0.059 - 0.118 | 39.2 | - | - |

| 3004 H19 | 0.118 - 0.250 | 39.2 | - | - |

| 3004 H22/32 | 0.008 - 0.020 | 27.6 | 34.8 | 4 |

| 3004 H22/32 | 0.020 - 0.059 | 27.6 | 34.8 | 5 |

| 3004 H22/32 | 0.059 - 0.118 | 27.6 | 34.8 | 6 |

| 3004 H22/32 | 0.118 - 0.250 | 27.6 | 34.8 | 7 |

| 3004 H22/32 | 0.236 - 0.394 | 27.6 | 34.8 | - |

| 3004 H24/34 | 0.008 - 0.020 | 31.9 | 38.4 | 3 |

| 3004 H24/34 | 0.020 - 0.059 | 31.9 | 38.4 | 4 |

| 3004 H24/34 | 0.059 - 0.118 | 31.9 | 38.4 | 4 |

| 3004 H24/34 | 0.118 - 0.250 | 31.9 | 38.4 | - |

| 3004 H26/36 | 0.008 - 0.020 | 34.8 | 41.3 | 3 |

| 3004 H26/36 | 0.020 - 0.059 | 34.8 | 41.3 | 3 |

| 3004 H26/36 | 0.059 - 0.118 | 34.8 | 41.3 | 3 |

| 3004 H26/36 | 0.118 - 0.250 | 34.8 | 41.3 | - |

| 3004 H28/38 | 0.008 - 0.020 | 37.7 | - | 2 |

| 3004 H28/38 | 0.020 - 0.059 | 37.7 | - | 3 |

| 3004 H28/38 | 0.059 - 0.118 | 37.7 | - | - |

| 3004 H28/38 | 0.118 - 0.250 | 37.7 | - | - |

| 3004 O/H111 | 0.008 - 0.020 | 22.5 | 29 | 13 |

| 3004 O/H111 | 0.020 - 0.059 | 22.5 | 29 | 14 |

| 3004 O/H111 | 0.059 - 0.118 | 22.5 | 29 | 15 |

| 3004 O/H111 | 0.118 - 0.250 | 22.5 | 29 | 16 |

Other Properties for 3004 Aluminum Plate

| 3004 | Properties |

|---|---|

| Machinability | The machinability of this alloy is considered to be excellent, especially in the hard temper. As is typical of the aluminum alloys an oil lubricant should be used for machining, although light cuts may be done dry. |

| Forming | AL 3004 is easily formed by either cold or hot working with conventional tooling. |

| Welding | The alloy is weldable by the standard methods. Best results are obtained by use of TIG or MIG welding with the same alloy as filler rod. |

| Heat Treatment | Heat treatment has no effect upon this alloy. It may be annealed after cold working however. See "Annealing". |

| Forging | Forging may be accomplished in the range of 950 to 700 F. |

| Hot Working | AL 3004 can be hot worked at temperatures of 900 to 500 F. |

| Cold Working | Cold working capability of this alloy is good. it can readily be cold worked up to a 75% reduction of area by conventional methods. Working beyond the 75% reduction requires an intermediate anneal. |

| Annealing | Anneal at 650 F and air cool. |

| Hardening/hardness | Cold working is the only means of producing the harder (H) tempers of this alloy. |

3004 Aluminum Plate Composition

| Element | Percentage |

|---|---|

| Aluminum | 95.7-98.2% |

| Magnesium | 0.8-1.3% |

| Manganese | 1.0-1.5% |

| Chromium | 0.05-0.25% |

| Iron | 0.7% max |

| Silicon | 0.3% max |

| Copper | 0.25% max |

| Zinc | 0.25% max |

| Titanium | 0.15% max |

| Other elements | 0.05% max |

What is Equivalent to 3004 Aluminum?

UNS A93004, ISO AlMn1Mg1, Aluminum 3004, AA3004, Al3004

The 3004 aluminum sheet plate provided by Haomei Aluminum meets the following standards:

- ASTM B209

- EN573

- EN 485

| Alloy Temper | Specifications (thickness*width*length) | Common uses |

|---|---|---|

| 3004/O | 0.2*281*C | Lamp holder material |

| 3004/H18 | 0.609*1244.6*C | coated roll |

| 3004/O | 1.2*1220*2440 | Ordinary board |

| 3004/H32 | 1.85*1250*2500 | Ordinary board |

| 3004/O | 0.032*629*C | container foil |

| 3004/O | 0.035*666*C | container foil |

| 3004/O | 0.035*725*C | container foil |

| 3004/O | 0.0365*658*C | container foil |

| 3004/O | 0.038*675*C | container foil |

| 3004/O | 0.04*544*C | container foil |

| 3004/O | 0.043*594*C | container foil |

| 3004/O | 0.045*350*C | container foil |

| 3004/O | 0.047*510*C | container foil |

| 3004/O | 0.047*794*C | container foil |

| 3004/O | 0.048*1140*C | container foil |

| 3004/O | 0.05*358*C | container foil |

| 3004/O | 0.05*590*C | container foil |

| 3004/O | 0.051*916*C | container foil |

| 3004/O | 0.052*404*C | container foil |

| 3004/O | 0.053*770*C | container foil |

| 3004/O | 0.054*319*C | container foil |

| 3004/O | 0.056*384*C | container foil |

| 3004/O | 0.058*497*C | container foil |

| 3004/O | 0.064*370*C | container foil |

| 3004/O | 0.07*535*C | container foil |

| 3004/O | 0.073*493*C | container foil |

| 3004/O | 0.074*485*C | container foil |

| 3004/O | 0.075*345*C | container foil |

| 3004/O | 0.075*538*C | container foil |

| 3004/O | 0.075*540*C | container foil |

| 3004/O | 0.075*597*C | container foil |

| 3004/O | 0.075*884*C | container foil |

| 3004/O | 0.078*366*C | container foil |

| 3004/O | 0.08*240*C | container foil |

| 3004/O | 0.08*286*C | container foil |

| 3004/O | 0.082*660*C | container foil |

| 3004/O | 0.087*554*C | container foil |

| 3004/O | 0.0875*720*C | container foil |

| 3004/O | 0.091*271*C | container foil |

| 3004/O | 0.114*500*C | container foil |

| 3004/O | 0.125*480*C | container foil |

| 3004/O | 0.137*425*C | container foil |

| 3004/O | 0.15*440*C | container foil |

| 3004/O | 0.155*611*C | container foil |

| 3004/O | 0.155*611*C | container foil |

| 3004/O | 0.17*611*C | container foil |

| 3004/O | 6*1000*6000 | medium plate |

What is the Difference between 3003 and 3004 Aluminum Plate?

Composition : The composition of 3003 aluminum is 97.5% aluminum, while the composition of 3004 aluminum is 95.8% aluminum and 1.2% manganese.

| Alloy | Mn | Mg |

|---|---|---|

| 3004 | 1.0 - 1.5 | 0.8 - 1.3 |

| 3003 | 1.0 - 1.5 | - |

Formability : Both alloys are highly formable and are commonly used in sheet metal processing. However, 3004 aluminum has slightly better formability because of the addition of manganese.

Corrosion Resistance : Both alloys have good corrosion resistance, but 3004 aluminum has better corrosion resistance in salt water environments due to the presence of manganese.

Strength : 3003 aluminum is a softer alloy with lower strength than 3004 aluminum.

Processing Methods :

| Alloy | Processing Methods |

|---|---|

| 3004 | Hot Rolled |

| 3003 | Cast and Hot Rolled |

Application :

- 3003 aluminum is commonly used in cookers, heat exchangers and roof panels

- 3004 aluminum is commonly used in the manufacture of beverage cans, building facades and storage tanks

What is Wrought Aluminum Manganese Alloy 3004?

Wrought Aluminum Manganese 3004 is a commonly used aluminum alloy whose main alloying element is manganese. It belongs to the 3xxx series of aluminum alloys, which are famous for their good formability, corrosion resistance and moderate strength.

The composition of Wrought Aluminum Manganese 3004 typically includes 95.8% Aluminum, 1.2% Manganese, 0.8% Magnesium and 0.15% Chromium. The addition of manganese gives the alloy better strength, formability and corrosion resistance.

Alloy 3004 is commonly used in sheet metal processing for the manufacture of cans, containers and other products requiring good formability. It is also commonly used in applications such as building curtain walls, storage tanks, heat exchangers, and beverage cans because of its excellent corrosion resistance and moderate strength.

Wrought Aluminum Manganese 3004 is usually supplied in plate, sheet and coil form and can be joined using common welding, brazing or soldering methods.