- What is 3003 Plate of Aluminum?

- What are the Advantages of 3003 Aluminum Plate?

- 3003 Aluminum Plate Physical Properties

- 3003 Aluminum Plate Specifications

- What is 3003 Aluminum Called?

- 3003 h14 Aluminum vs 6061 T6

- What is the Difference between 3003 and 6061 Aluminum Plates?

- What is 3003 Aluminum Plate Used for?

- What is the Difference between 3003 and 3004 Aluminum?

- What is the Strength of 3003 Aluminum Sheet?

- 3003 Aluminum Plate Sheet Chemical Composition

- 3003 Aluminum Plate More Infos

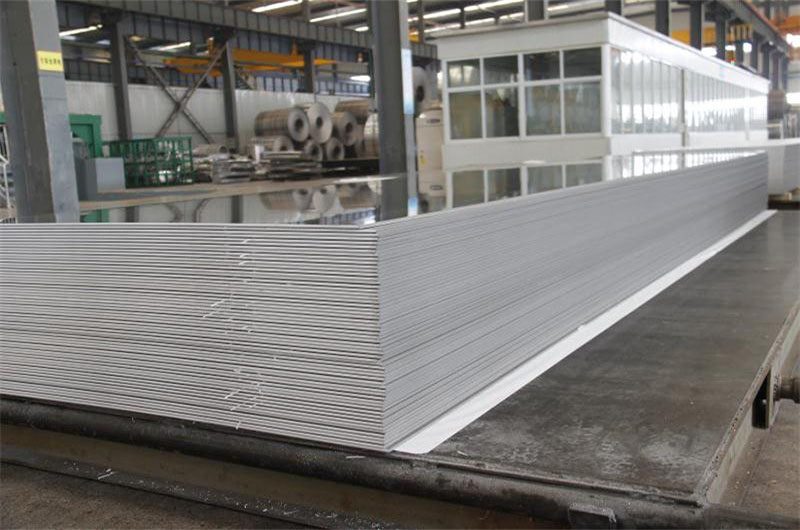

What is 3003 Plate of Aluminum?

3003 aluminum plate refers to a flat aluminum plate made of 3003 alloy. These sheets come in a variety of thicknesses, widths and lengths and are commonly used in applications such as roofing, cladding, chemical equipment and cookware.

3003 aluminum is available in a variety of tempers, including H14, which is strain hardened and partially annealed for excellent workability and formability. It is commonly used for deep drawing, spinning and other forming applications.

Compared with 6061 aluminum, 3003 aluminum has lower strength and hardness, but higher formability and corrosion resistance. 6061 aluminum is typically used in structural applications requiring high strength, while 3003 aluminum is used in lighter weight applications where formability and corrosion resistance are more important.

What are the Advantages of 3003 Aluminum Plate?

- Corrosion resistance : One of the biggest advantages of 3003 aluminum is its excellent corrosion resistance. It is especially suitable for applications exposed to moisture and other harsh environments.

- Formability : 3003 aluminum has good formability and can be easily formed into various shapes. This makes it a popular choice for applications requiring complex shapes or complex designs.

- Weldability : 3003 aluminum is easily weldable and can be joined using a variety of welding techniques. This makes it a popular choice for applications requiring soldering or other types of metal connections.

- Strength : While not as strong as some other aluminum alloys, 3003 aluminum still has good strength and can be used in applications requiring moderate strength.

- Cost-Effective : 3003 Aluminum is an economical alternative to some more expensive aluminum alloys, making it a popular choice for a wide range of applications.

3003 Aluminum Plate Physical Properties

| Infomations | 3003-O | 3003-H14 | 3003-H22 |

| Shear Strength | 75MPa | 96MPa | 81MPa |

| Tensile Strength | 40-110MPa | 130-160MPa | 94-140MPa |

| Elastic Modulus | 70GPa | 70GPa | 70GPa |

| Hardness Brinell | 28HB | 42HB | 37HB |

| Elongation | 28% | 8% | 8% |

3003 Aluminum Plate Specifications

3003 aluminum sheet is available in a variety of thicknesses, typically 0.025" to 0.25" (0.635mm to 6.35mm).

- Thickness : 0.2mm - 6.0mm

- Width : 100mm - 2600mm

- Length : up to 12000mm

- Status : O, H12, H14, H16, H18, H22, H24, H26, H32, H34, H36, H38

- Surface treatment : polished, bright, anodized, embossed, brushed, etc.

What is 3003 Aluminum Called?

3003 aluminum is a special type of aluminum alloy, often referred to simply as "3003". It is also sometimes referred to as "Aluminum 3003", "AA3003" or simply "Alloy 3003". The Aluminum Association (AA) designates this alloy as AA3003.

3003 h14 Aluminum vs 6061 T6

3003-H14 aluminum and 6061-T6 aluminum are different alloys with different properties. Compared with 6061-T6, 3003-H14 has lower strength and hardness, but better formability and corrosion resistance. The choice between the two depends on the specific application and desired properties.

What is the Difference between 3003 and 6061 Aluminum Plates?

The main difference between 3003 and 6061 aluminum sheets is their composition and properties. 3003 aluminum has a higher manganese content, so it is more corrosion resistant than 6061 aluminum, but has lower strength, while 6061 aluminum has a higher magnesium and silicon content, and better strength and machinability.

What is 3003 Aluminum Plate Used for?

Roofing and Siding

- Thickness : 0.2mm - 6.0mm

- Width : 1000mm - 2000mm

- Length : up to 12000mm

- Status : H14, H16, H18, H22, H24, H26

- Surface treatment : polished, coated or painted

Cookware

- Thickness : 0.2mm - 6.0mm

- Width : up to 1200mm

- Length : up to 6000mm

- Status : H12, H14, H16, H18, H22, H24

- Surface treatment : polished or coated

Stair Treads and Steps

- Thickness : 1.5mm - 6.0mm

- Width : 1000mm - 2000mm

- Length : up to 12000mm

- Status : H22, H24, H114, H194

- Pattern : five or rhombus

- Surface Finish : Polished, Bright or Coated

Vehicle Flooring and Toolboxes

- Thickness : 2.0mm - 5.0mm

- Width : 1000mm - 2000mm

- Length : up to 6000mm

- Status : H22, H24, H114, H194

- Pattern : five or rhombus

- Surface treatment : polished or coated

Decorative

- Thickness : 1.5mm - 3.0mm

- Width : 1000mm - 2000mm

- Length : up to 6000mm

- Status : H22, H24

- Pattern : custom design or diamond

- Surface treatment : polished or coated

Heat Exchangers

- Thickness : 0.5mm - 5.0mm

- Width : up to 1500mm

- Length : up to 6000mm

- Status : O, H14, H16, H18

- Surface treatment : polished, coated or painted

Chemical Equipment

- Thickness : 1.0mm - 6.0mm

- Width : up to 2000mm

- Length : up to 12000mm

- Status : H14, H16, H18, H22, H24, H26

- Surface treatment : polished, coated or painted

Storage Tank

- Thickness : 0.5mm - 5.0mm

- Width : up to 2000mm

- Length : up to 12000mm

- Status : H14, H16, H18, H22, H24

- Surface treatment : polished, coated or painted

Electrical Components

- Thickness : 0.2mm - 6.0mm

- Width : up to 2000mm

- Length : up to 6000mm

- Status : O, H12, H14, H16, H18, H22, H24

- Surface treatment : polished or coated

What is the Difference between 3003 and 3004 Aluminum?

The main difference between 3003 and 3004 aluminum is that magnesium is added to 3004, which makes it have higher strength and better corrosion resistance than 3003.

What is the Strength of 3003 Aluminum Sheet?

The strength of 3003 aluminum plate depends on the state after tempering or processing. For example, the tensile strength of 3003-H14 aluminum plate is 145-185MPa, while the tensile strength of 3003-H18 aluminum plate is 185-215MPa.

3003 Aluminum Plate Sheet Chemical Composition

| Alloy | 3003 |

|---|---|

| Si | 0.6 |

| Fe | 0.7 |

| Cu | 0.05-0.20 |

| Mn | 1.0-1.5 |

| Mg | - |

| Cr | - |

| Zn | 0.10 |

| Ti | - |

| Al | Remainder |

3003 Aluminum Plate More Infos

- Hardness Brinell: 40

- Poissons Ratio: 0.33

- Modulus of Elasticity: 10, 000 ksi

- Shear Modulus: 3, 630 ksi

- Shear Strength: 14, 000 psi

- Melting Point: 1, 190-1, 210 F

- Density: 0.1 lb/in3

- Ultimate Tensile Strength: 22, 000 psi

- Yield Tensile Strength: 21, 000 psi

- Fatigue Strength: 9, 000 psi