- What is 3003 Aluminum Foil?

- 3003 Aluminum Foil Features

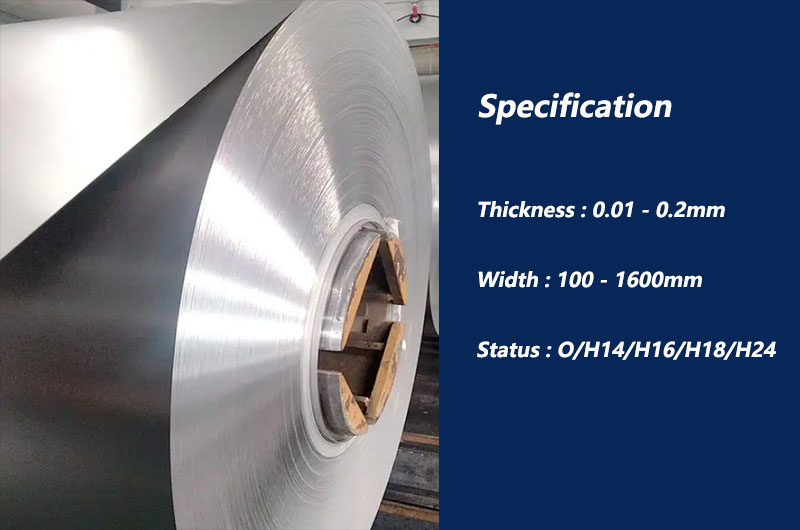

- 3003 Aluminum Foil Specification

- Mechanical Properties of 3003 Aluminum Foil

- Typical 3003 Aluminum Foil Introduction

- Physical Properties of 3003 Aluminum

- Chemical Composition of 3003 Aluminum

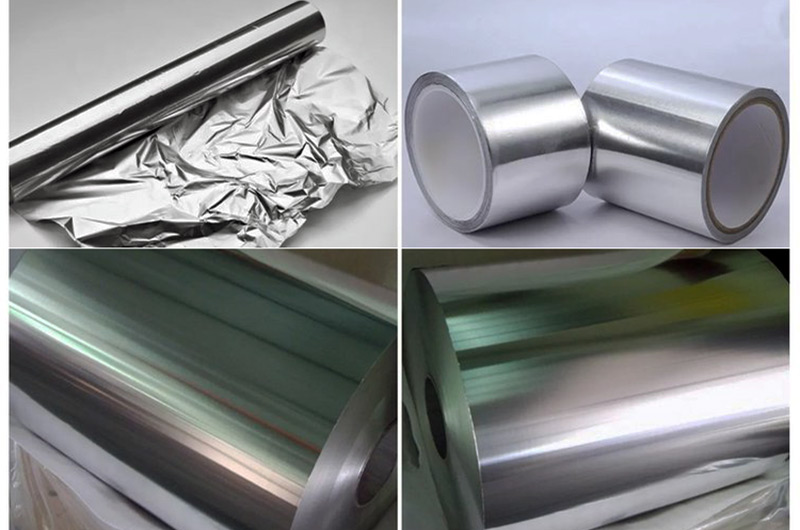

- 3003 Aluminum Foil Application

What is 3003 Aluminum Foil?

3003 aluminum foil is an alloy primarily made from aluminum, with manganese as the major alloying element. It belongs to the 3xxx series of aluminum alloys and is known for its excellent corrosion resistance and formability.

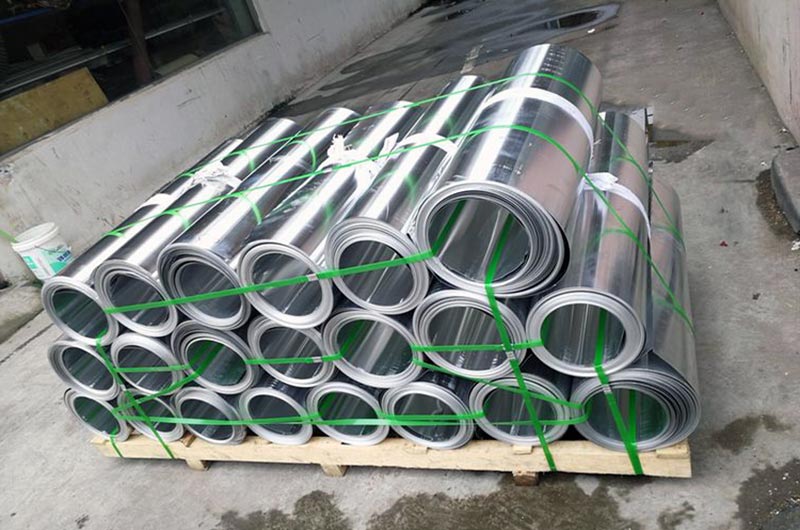

3003 aluminum foil needs to be stored in a dry, cool, and ventilated environment to avoid being affected by moisture, high temperature, etc., which will affect the quality. During transportation, it is also necessary to protect the aluminum foil from being affected by extrusion and collision.

Haomei Aluminum adopts advanced production equipment. In the production process, strict quality control is carried out for each production link, and problems are found and solved in time to ensure that the quality of aluminum foil meets the requirements.

3003 Aluminum Foil Features

- Good Corrosion Resistance : 3003 aluminum foil has excellent corrosion resistance, which makes it ideal for a wide range of applications including packaging and heat exchangers.

- Good Formability : Strong formability, can be easily processed into various shapes and sizes for different applications.

- Good weldability : good weldability, it is easy to connect with other materials to form a strong bond.

- High Conductivity : 3003 aluminum is highly conductive, which makes it a popular choice for electrical applications such as capacitors.

- Non - Toxic and Odorless : Non - toxic and odorless, safe for food packaging applications.

- Recyclable : 3003 aluminum is fully recyclable, making it an environmentally friendly choice for a wide range of applications.

3003 Aluminum Foil Specification

- Thickness : 0.01 - 0.2mm

- Width : 100 - 1600mm

- Length : Coiled

- Status : O/H14/H16/H18/H24

- Implementation standards : National Standard, American Standard, European Standard, Russian Standard, Japanese Standard, etc.

Mechanical Properties of 3003 Aluminum Foil

| Temper | Tensile Strength |

|---|---|

| 3003 O Aluminum | 95 - 135 MPa |

| 3003 H14 Aluminum | 140 - 185 MPa |

| 3003 H16 Aluminum | 170 - 215 MPa |

| 3003 H18 Aluminum | 190 - 235 MPa |

| Temper | Yield Strength |

|---|---|

| 3003 O Aluminum | 35 - 75 MPa |

| 3003 H14 Aluminum | 120 - 160 MPa |

| 3003 H16 Aluminum | 150 - 190 MPa |

| 3003 H18 Aluminum | 170 - 210 MPa |

| Temper | Elongation |

|---|---|

| 3003 O Aluminum | 35 - 45% |

| 3003 H14 Aluminum | 2 - 10% |

| 3003 H16 Aluminum | 1 - 8% |

| 3003 H18 Aluminum | 1 - 6% |

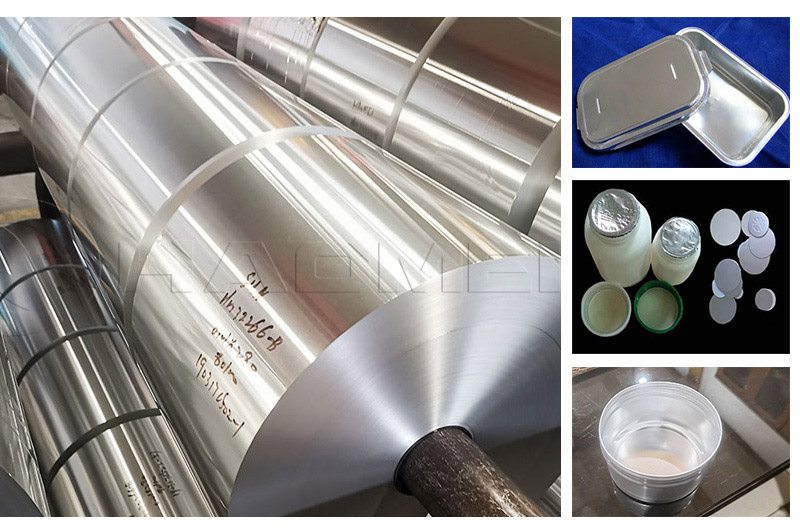

Typical 3003 Aluminum Foil Introduction

3003 O Aluminum Foil

- Uses : Mainly used in industrial applications that require high corrosion resistance, such as heat exchangers, condenser fins, etc.

- Examples : heat exchangers, condenser fins, and air conditioning evaporators.

- Advantages : good ductility, excellent corrosion resistance, high formability, good surface finish.

- Specifications : thickness 0.016mm - 0.2mm, width 100mm - 1600mm.

3003 H14 Aluminum Foil

- Application : It is often used in packaging applications, such as food packaging and container production, and is also used to make power battery soft connections, electronic product soft connections, transformer gaskets, etc.

- Examples : Foil containers, yogurt lids and bottle caps for food packaging.

- Advantages : good formability, strong surface tension, excellent deep drawing performance.

- Specifications : thickness 0.016mm - 0.2mm, width 100mm - 1600mm.

3003 H16 Aluminum Foil

- Application : Used in the production of air - conditioning ducts, insulation materials and other applications requiring high strength.

- Examples : Air conditioning ducts, heat exchanger fins and building insulation.

- Advantages : good elongation, excellent deep drawing performance, good strength, high formability and excellent corrosion resistance.

- Specifications : thickness 0.016mm - 0.2mm, width 100mm - 1600mm.

3003 H18 Aluminum Foil

- Uses : Widely used in the production of electronic and electrical components, and also used in the production of air - conditioning heat exchanger fins, household foil, and cable wrapping foil.

- Examples : Capacitor housings, transformer windings and other electronic components.

- Advantages : high strength, good formability, excellent corrosion resistance.

- Specifications : thickness 0.02mm - 0.2mm, width 100mm - 1600mm.

Physical Properties of 3003 Aluminum

| Property | Value |

|---|---|

| Density | 2.73 g/cm3 |

| Melting Point | 655 - 675 °C |

| Thermal Conductivity | 156 W/(m·K) |

| Electrical Conductivity | 35% IACS |

Chemical Composition of 3003 Aluminum

| Property | 3003 |

|---|---|

| Si (%) | 0.6 |

| Fe (%) | 0.7 |

| Cu (%) | 0.05 - 0.20 |

| Mn (%) | 1.0 - 1.5 |

| Mg (%) | - |

| Zn (%) | 0.1 |

| Ti (%) | - |

| Other | 0.15 |

| Al (%) | Remainder |

3003 Aluminum Foil Application

3003 aluminum foil is mainly used in electronic components (electronic foil), honeycomb materials, sound insulation of building materials (viaducts, high - speed railway road sound insulation, etc.), and as food packaging foil (3003 aluminum foil packaging bags, vacuum aluminum foil bags) and other industries.

| Application | Example | Alloy and Temper | Advantages | Specification (mm) - Thickness x Width |

|---|---|---|---|---|

| Food packaging | Snacks, chocolates, etc. | 3003 - H24, 3003 - H18 | Good barrier properties, high formability, corrosion - resistant | 0.018 - 0.2 x 100 - 1600 |

| Heat exchangers | Air conditioners, car radiators, etc. | 3003 - H22, 3003 - H24 | High heat exchange efficiency, good formability, corrosion - resistant | 0.08 - 0.2 x 400 - 1200 |

| Roofing and cladding | Roofs, walls, facades, etc. | 3003 - H14, 3003 - H16 | Lightweight, corrosion - resistant, easy to install and maintain | 0.2 - 3.0 x 1000 - 2600 |

| Insulation | Thermal insulation, moisture - proofing, etc. | 3003 - H24 | Good insulation, moisture - proof, easy to process and install | 0.02 - 0.2 x 100 - 1600 |

| Capacitor foil | Capacitors | 3003 - H18, 3003 - H22, 3003 - H24 | Good electrical conductivity, stable performance, easy to process | 0.02 - 0.05 x 100 - 600 |

| Lithium - ion battery | Batteries | 3003 - H14, 3003 - H16 | High safety, good electrical conductivity, good formability | 0.03 - 0.2 x 100 - 1200 |

| Industrial applications | Chemical equipment, storage tanks, etc. | 3003 - H14, 3003 - H16, 3003 - H18, 3003 - H22, 3003 - H24 | High strength, good formability, corrosion - resistant | 0.2 - 3.0 x 1000 - 2600 |

3003 Container Foil

Among container foils, 3003 aluminum foil is used because of its good formability, high corrosion resistance, and excellent moisture resistance. 3003 container foil is often used to make food container products such as lunch boxes, fast food packaging, and takeaway containers.

- Status : O

- Thickness : 0.03 - 0.20mm

- Width : 200 - 1600mm

3003 Packaging Foil

In terms of packaging foil, 3003 aluminum foil is also widely used because of its good formability, high corrosion resistance, and excellent barrier properties. It is often used for packaging food, medicine, beverages, and cigarettes that need to be protected from light, moisture, and oxygen.

- Status : H18

- Thickness : 0.018 - 0.2mm

- Width : 100 - 1600mm

3003 Electronic Foil

Among electronic foils, 3003 aluminum foil is widely used due to its high purity, good electrical conductivity, and good formability.

It is often used in the production of electronic products such as electrolytic capacitors, lithium - ion battery components, electronic components, and battery packaging.

- Status : H24

- Thickness : 0.02 - 0.05mm

- Width : 100 - 1000mm

3003 h24 Lunch Box Aluminum Foil

Aluminum foil lunch box is a new type of environmentally friendly lunch box, using 3003 aluminum foil as raw material. 3003 aluminum foil is soft in texture, easy to process and shape, good airtightness, good wrapping performance, and good high temperature resistance and oil resistance.

3003 Aluminum Foil Honeycomb Core Raw Material

The aluminum honeycomb panel is a composite panel made of high-strength alloy aluminum plate as the surface and bottom plate, 3003 aluminum foil as the core material, and manufactured through high temperature and high pressure compounding. The honeycomb material has high wind pressure resistance, shock absorption, sound insulation, heat preservation, and flame retardancy And other excellent properties, it is the preferred material for building exterior wall decoration.

Egg Tart Tray 3003 Aluminum Foil

3003 aluminum foil for egg tart cups has multiple advantages such as food grade, clean oil removal, less holes, good product shape, and no deformation when cutting. In addition, it is one of the essential raw materials for egg tart cups because of its good airtightness, clean surface and no foreign matter, hygienic and safe.

3003 Aluminum Foil for Air Conditioner Fins

Air-conditioning aluminum foil is generally used for 3003 aluminum foil. It mainly has good formability. Its structure and properties must be uniform, with few metallurgical defects and small anisotropy. At the same time, it requires high strength, good ductility, uniform thickness, and good flatness.