- What is 1235 Aluminum Foil?

- The Main Properties of 1235 Aluminum Foil

- 1235 Aluminum Foil Specifications

- Advantages of 1235 aluminum foil

- 1235 Aluminum Foil Product Quality

- Mechanical Properties of 1235 Aluminum Foil

- Aluminum Foil Product Quality

- Physical Properties of 1235 Aluminum Foil

- Chemical Composition of 1235 Aluminum Foil

- What are the Common Uses of 1235 Aluminum Foil?

What is 1235 Aluminum Foil?

1235 aluminum foil is a high-purity aluminum alloy with a minimum aluminum content of 99.35%. 1235 o aluminum alloy foil has strong ductility and is easy to process and shape.

The market price of 1235 aluminum foil is relatively cheap and cost-effective. 1235 and 1145 alloys are very similar, containing almost the same chemical composition and the same physical properties. Sometimes 1235 can be used as a replacement for 1145 alloy.

The Main Properties of 1235 Aluminum Foil

- High ductility: 1235 foil can be easily formed, bent and molded into different shapes without cracking or breaking.

- Excellent thermal and electrical conductivity: 1235 aluminum foil has high thermal and electrical conductivity, which makes it a popular choice for electrical applications.

- Lightweight: This foil is very light, making it easy to handle and transport.

- Good corrosion resistance: Aluminum foil is highly resistant to corrosion, which makes it an excellent choice for packaging applications.

- Barrier properties: Aluminum foil 1235 has strong barrier properties, oxidation resistance, water resistance, and moisture resistance.

- Safety: 1235 aluminum foil has stable chemical properties and high safety. It has great advantages for packaging food.

- Weather resistance: Aluminum foil has the characteristics of high temperature resistance, low temperature resistance and oil resistance.

1235 Aluminum Foil Specifications

- Thickness : 0.006mm - 0.2mm

- Width : 100mm - 1600mm

- Soft state : O/H

- Length : can be customized according to customer requirements

- Standard : QQA-1876, ASTM B479

| Thickness | Applications |

|---|---|

| 0.006mm - 0.014mm | Packaging material : food packaging, tobacco packaging, etc. |

| 0.015mm - 0.07mm | Packaging material : beverage packaging, pharmaceutical packaging, etc. |

| Electrical material : capacitors, batteries, electronic components, etc. | |

| 0.08mm - 0.2mm | Industrial material : heat exchangers, solar panels, building materials, chemical containers, automotive parts, etc. |

Advantages of 1235 aluminum foil

1235 aluminum foil, like other aluminum foil products, has the characteristics of non-toxic, tasteless, moisture-proof, light-shielding, high reflectivity, good formability, high air tightness, and fragrance retention.

- As one of the pure aluminum foil series products, it has good rust resistance and solubility. It does not deform when cut, the sticker is not easy to fall off, and the printing effect is good.

- Using 1235 aluminum foil as raw material, after subsequent lamination, printing, bonding and other processes, it has the advantages of good heat insulation, strong adhesion, and anti-aging.

Haomei Aluminum can process 1235 aluminum foil with a thickness of 0.018-0.5mm. Due to its excellent rust resistance, formability, and dissolving ability, this product is widely used in cigarette packaging, cables, capacitors, tapes, battery foils, flexible packaging, etc.

1235 Aluminum Foil Product Quality

Haomei Aluminum strictly controls raw materials, adopts reasonable processes, and conducts layer-by-layer inspections during the production process to ensure that the produced 1235 tape foil has no oil stains, uniform color, few pinholes, good product shape, and no obvious roll marks, pits, or pins. Holes, corrosion and other traces.

- 1. Strictly control the width and thickness of the finished product, and ensure that the upper and lower thickness is within 4%;

- 2. Ensure slice quality, end faces are aligned, and there are no burrs, tower shapes, etc.;

- 3. The layout is smooth, without burrs, oil spots, black oil spots, bright lines, roller marks, unevenness, etc.

Mechanical Properties of 1235 Aluminum Foil

| Product Type | Alloy Temper | Thickness(mm) | Tensile Strength(Mpa) | Elongation(%)A100mm |

| Food and Household Foil | 1235 O | 0.01-0.024 | 40-100 | ≥1 |

| 0.025-0.04 | 45-100 | ≥2 | ||

| 0.041-0.07 | 45-100 | ≥4 | ||

| 1235 H18 | 0.01-0.07 | ≥135 | – | |

| aluminium foil for capacitor | 1235 H18 | 0.02-0.05 | ≥135 | – |

| aluminium foil for cable | 1235 O | 0.01-0.024 | 40-100 | ≥1 |

| 0.025-0.04 | 45-100 | ≥2 | ||

| 0.041-0.07 | 45-100 | ≥4 | ||

| aluminium foil for adhesive tape | 1235 O | 0.012-0.04 | 50-90 | ≥1 |

| 1235 H18 | ≥135 | – | ||

| 1235 O | 0.03-0.07 | 60-100 | ≥2 |

Aluminum Foil Product Quality

- Chemical composition : It meets the chemical composition standard, the aluminum content should not be less than 99.35%, and the content of other elements should meet the requirements of relevant standards.

- Physical properties : Physical properties such as density, melting point, thermal conductivity and thermal expansion coefficient should meet the requirements of relevant standards.

- Surface quality : The surface of 1235 aluminum foil is smooth and flat, without obvious defects such as bumps and cracks, and without impurities, oxide scales, oil stains and other pollutants.

- Dimensional accuracy : The size of 1235 aluminum foil meets the requirements of relevant standards, such as thickness, width and length, etc. should be within the allowable range.

- Mechanical properties : The mechanical properties meet the requirements of relevant standards, such as tensile strength, elongation and folding times, etc., which should meet or exceed the requirements specified in the standards.

Physical Properties of 1235 Aluminum Foil

| Property | Value |

|---|---|

| Density | 2.7 g/cm3 |

| Melting point | 647 - 657 °C |

| Thermal conductivity | 235 W/(m·K) |

| Coefficient of thermal expansion | 23.8 × 10 - 6/K |

Chemical Composition of 1235 Aluminum Foil

| Aluminum (Al): | 99.35% |

| Chromium (Cr): | - |

| Copper (Cu): | 0.05% |

| Iron (Fe): | - |

| Magnesium (Mg): | 0.05% |

| Manganese (Mn): | 0.05% |

| Other Total: | - |

| Silicon (Si): | 0.65% (Si+Fe) |

| Titanium (Ti): | 0.06% |

| Zinc (Zn): | 0.10% |

What are the Common Uses of 1235 Aluminum Foil?

1235 aluminum foil has a wide range of applications, including:

- Packaging: It is commonly used for packaging food, pharmaceuticals, and other products due to its purity and ability to protect contents from moisture, light, and contaminants.

- Electrical Applications: Due to its high electrical conductivity, it's used in capacitors, insulation, and other electrical components.

- Insulation: It is used for thermal insulation in the construction industry.

- Decoration: It can be embossed or laminated for decorative purposes in the packaging industry.

| Category | Temper | Thickness (mm) | Application |

| Aluminum Foil Tape | O | 0.015-0.03 | Made from 1235 aluminum foil as the base material, processed with lamination, printing, and adhesive coating; it features good thermal insulation, strong adhesion, and aging resistance. |

| Cable | O | 0.015-0.05 | Used as an insulation layer in cables, offering good conductivity, insulation, and corrosion resistance. |

| Lithium-Ion Battery | H14 | 0.012-0.02 | Used as a separator material in the production of lithium-ion batteries. |

| Insulation | O | 0.015-0.02 | The high reflectivity and thermal conductivity of 1235 aluminum foil make it an excellent choice for insulation, especially in the construction industry. |

| Electrical Applications | H14 | 0.015-0.05 | Due to its good conductivity, it can be used to produce capacitors, cables, and other electrical components. |

| Heat Exchanger | O | 0.015-0.05 | Used in heat exchangers due to its thermal conductivity and corrosion resistance. |

| Flexible Packaging | O | 0.012-0.02 | Used in the food and pharmaceutical industries for items like pouches and blister packs. |

| Cigarette Packaging | O | 0.006-0.007 | Commonly used as a lining for cigarette packaging to protect the product from moisture and oxygen. |

1235 Aluminum Foil Packaging

1235 aluminum foil is different from 8011 aluminum foil. 1235 aluminum foil is usually softer. 1235 aluminum foil is used in combination with other packaging materials for milk packaging, cigarette packaging, beverage packaging, and food packaging. Supermarket snack bags, cigarette bags, and chocolate bars are all made of 1235 aluminum foil. It becomes an extremely thin flexible packaging aluminum foil, 0.006mm-0.009mm.

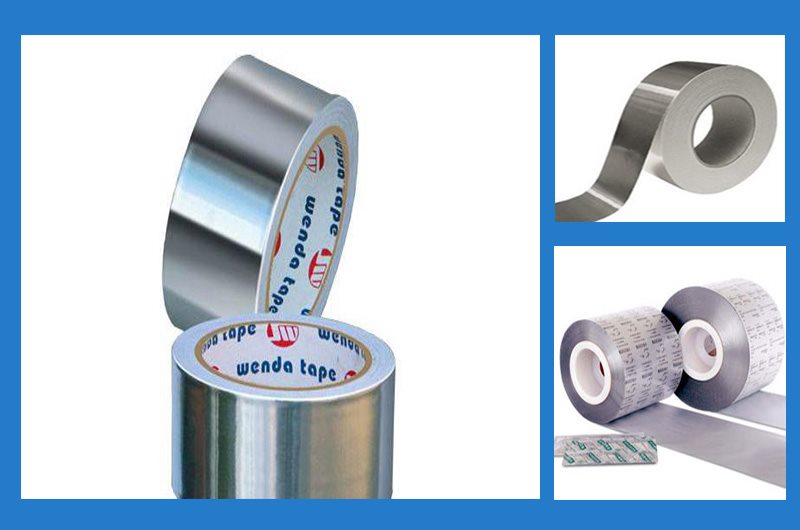

1235 Aluminum Foil Tape

- Status : O/H18

- Thickness : 0.01mm - 0.05mm

There are many tape foils on the market that use 1235 aluminum foil O-state alloy.

1235 Cable Aluminum Foil

- Alloy status: 1235-O.

- Thickness: 0.006~0.04.

- Processing method: Aluminum-plastic composite is processed into narrow strips.

- Purpose: Wrap weak wires to provide shielding.

1235 Aluminum Foil for Stamping Bottle Caps

1235 aluminum foil is often used to punch aluminum bottle caps. Aluminum bottle caps combine aesthetics, airtightness and printing effects, and are currently the most commonly used bottle caps in beverage, wine, cosmetics, and medical and health care industries.

1235 h18 Aluminum for Sealing Aluminum Foil Gasket

The sealing aluminum foil gasket is made of 1235h18 aluminum foil. 1235 aluminum foil has good antirust properties, formability, and fusion properties, and is widely used in cable tapes, tape foils, battery foils, and bottle cap materials.

1235 Aluminum Foil for Lithium Battery

Battery aluminum foil refers to the aluminum foil used as the positive electrode material of lithium-ion batteries. 1235 pure aluminum foil has relatively high purity and good conductivity, so it is often used as battery foil.

- Alloy status: 1235-H18, 1060-H18, 1070-H18.

- Typical thickness: 0.012~0.035.

- End use: Products for use in lithium-ion battery current collector materials.

1235 Aluminum foil for Capacitors

- Alloy status: 1235-O.

- Typical thickness: 0.0045~0.009.

- Processing method: oil lined paper.

1235 Aluminum Foil for Insulation

1235 aluminum foil is a popular choice for insulation due to its excellent thermal conductivity and reflectivity. It is widely used in cables and is also used extensively in the construction industry for building insulation, and in the automotive industry for engine component insulation.

1235 Laminate Aluminum Foil

1235 aluminum foil is often used as a laminate with other materials such as paper and plastic. Aluminum foil for laminated plastics can improve the barrier properties and strength of packaging materials.

1235 aluminum foil can be used as industrial materials, such as heat exchangers, solar panels, building materials, chemical containers, auto parts, etc. It has good corrosion resistance, machinability and weldability, and can meet the needs of different industrial fields.