- Introduction to 1100 Aluminum Plates

- 1100 Aluminum Sheet Standards

- 1100 Aluminum Sheet Advantages Disadvantages

- Equivalents of AA 1100

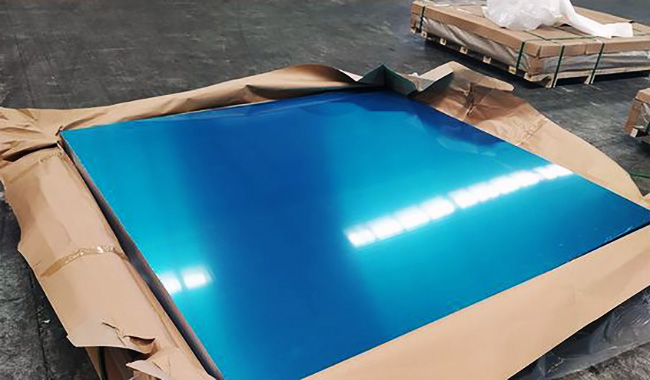

- 1100 Aluminum Plate Features

- Composition of 1100 Aluminum Plate

- 1100 Aluminum Plate Mechanical Properties

- 1100 Aluminum Sheet More Informations

- Physical Properties of 1100 Aluminum Alloy

- 1100 Aluminum Sheet Thermal Properties

- 1100 Aluminum Plate Corrosion Resistance

- Mechanical Properties

- 1100 Aluminum Plate Electrical Conductivity

- Machinability and Weldability

- 1100 Aluminum Plate Applications

- Conclusion

Introduction to 1100 Aluminum Plates

Aluminum alloys are materials primarily composed of aluminum as the base metal with various other elements added. These alloying elements enhance the properties of aluminum to suit specific applications. Aluminum alloys are categorized into different series, each serving a unique purpose. The 1000 series, in particular, includes aluminum alloys with a purity of at least 99.0% aluminum and minimal alloying elements. Among these, the 1100 aluminum plate is notable for its high purity.

1100 Aluminum Sheet Standards

- ASTM B209

- EN573

- EN485

- QQ-A-250/1

1100 Aluminum Sheet Advantages Disadvantages

Advantages

- Excellent thermal conductivity

- Excellent corrosion resistance

- Excellent machinability

- High weldability

- High thermal conductivity

Disadvantages

Due to its low tensile strength and softness, 1100 aluminum sheet is not used for high strength or high pressure applications.

Equivalents of AA 1100

UNS A91100, Aluminium 1100, AA1100, Al1100

1100 Aluminum Plate Features

- 1.Soft and ductile, 1100 aluminum plate has excellent machinability in all states.

- 2.1100 aluminum has good weldability.

- 3.Excellent machinability makes it ideal for applications requiring advanced forming. This aluminum can be formed into many different shapes and forms through cold working.

Composition of 1100 Aluminum Plate

The 1100 aluminum plate is classified under the 1000 series of aluminum plates, characterized by its high aluminum content. Its chemical composition is as follows:

| Si | Fe | Cu | Mn | Zn | Others | Al |

| 0.95% max | 0.40% max | 0.05% max | 0.05% max | 0.10% max | 0.05% max | 99.00% min |

The purity of 1100 aluminum makes it an excellent choice for applications where high electrical conductivity is essential, and where resistance to corrosion is not a critical factor.

1100 Aluminum Plate Mechanical Properties

The mechanical properties of 1100 aluminum plate are as follows:

| Alloy-Temper |

Tensile Strength (ksi) |

Yield Strength (ksi) |

Elongation (%) |

| 1100-O | 13 | 5 | 30 |

| 1100-H14 | 18 | 17 | 3 |

| 1100-H18 | 24 | 22 | 2 |

These properties make 1100 aluminum a relatively soft and ductile material, well-suited for applications that require forming, bending, and deep drawing. It may not be as strong as some other aluminum alloys, but it serves its purpose in specific use cases.

1100 Aluminum Sheet More Informations

- Density: 0.1 lb/in3

- Fatigue Strength: 7, 000 psi

- Hardness Brinell: 32

- Melting Point: 1, 190-1, 215 F

- Modulus of Elasticity: 10, 000 ksi

- Poissons Ratio: 0.33

- Shear Modulus: 3, 7700 ksi

- Shear Strength: 11, 000 psi

- Ultimate Tensile Strength: 18, 000 psi

- Yield Tensile Strength: 13, 800 psi

Physical Properties of 1100 Aluminum Alloy

Physical properties are fundamental characteristics of any material. For 1100 aluminum alloy, the following physical properties are noteworthy:

- Density: 2.70 g/cm³ (0.0975 lb/in³)

- Melting Point: 660.3°C (1220.5°F)

- Electrical Resistivity: 2.67 x 10⁻⁸ ohm-meters

The low density of 1100 aluminum contributes to its lightweight nature, which is a significant advantage in applications where weight is a critical factor.

1050, 1060, 1070, 1100: These alloys have similar physical properties, including low density, a melting point of approximately 660.3°C (1220.5°F), and good electrical resistivity.

1100 Aluminum Sheet Thermal Properties

Aluminum alloys, including 1100, possess excellent thermal properties:

- Thermal Conductivity: 229 W/m·K (133 BTU·in/ft²·hr·°F)

- Coefficient of Thermal Expansion (CTE): 23.6 µm/m°C (13.1 µin/in°F)

The high thermal conductivity of 1100 aluminum makes it ideal for applications that require heat dissipation, such as heat sinks and cooling fins. Its CTE is relatively low, indicating good dimensional stability over a wide temperature range.

1100 Aluminum Plate Corrosion Resistance

- 1100: Exhibits good corrosion resistance, especially in moist or mildly corrosive environments, making it versatile for many applications.

- 1050: Offers moderate corrosion resistance, making it suitable for applications in moderately corrosive environments.

- 1060: Provides good corrosion resistance, particularly in atmospheric and freshwater environments.

- 1070: Offers good corrosion resistance in various atmospheric conditions and is suitable for applications where corrosion is a concern.

Mechanical Properties

- 1100: Provides mechanical properties similar to 1060 and 1070, offering a balance between formability and strength.

- 1050: Offers relatively low tensile strength and yield strength, making it suitable for applications where strength is not the primary consideration.

- 1060: Provides moderate mechanical properties, making it useful in applications requiring both formability and strength.

- 1070: Offers higher tensile and yield strength compared to 1050 and 1060, but it is still considered a soft aluminum alloy.

1100 Aluminum Plate Electrical Conductivity

1050, 1060, 1070, 1100: All of these aluminum alloys in the 1000 series exhibit high electrical conductivity, with values close to that of pure aluminum. They are commonly used in electrical and electronic applications for efficient current transmission.

Machinability and Weldability

1050, 1060, 1070, 1100: These alloys are known for their excellent machinability and weldability. They can be easily machined and welded using various methods, making them versatile for manufacturing processes.

1100 Aluminum Plate Applications

- 1100: Used in a wide range of applications, including electrical wires, heat sinks, reflectors, lithographic plates, HVAC components, and reflective insulation.

- 1050: Commonly used in applications where corrosion resistance is not critical, such as chemical equipment, food industry, and signage.

- 1060: Found in applications requiring a balance between formability and strength, including cookware, heat exchangers, and reflective lighting.

- 1070: Suitable for electrical conductors, radiators, and heat exchangers due to its good electrical conductivity and formability.

| Alloy status | specifications (thickness*width*length) |

|---|---|

| 1100/H26 | 0.48*780*C |

| 1100/H24 | 1.18*1000*2000 |

| 1100/H24 | 2*1525*C |

| 1100/H18 | 0.143*630*C |

Conclusion

In summary, the 1000-series aluminum plates, including 1050, 1060, 1070, and 1100, offer various levels of corrosion resistance, mechanical properties, and applications.

- While 1050 and 1060 are often chosen for their balance between formability and strength

- 1070 and 1100 provide better corrosion resistance and electrical conductivity.

The choice among these alloys depends on the specific requirements of the application, including environmental conditions, mechanical properties, and electrical conductivity. Understanding these differences is essential for selecting the most suitable aluminum alloy for a given engineering or manufacturing need.