- Basic Information about 1100 Aluminum Discs

- Performance of 1100 Aluminum Discs

- 1100 Aluminum Discs Common Tempers

- 1100 Aluminum Discs Common Specifications

- 1100 Aluminum Disc Quality

- Advantages of 1100 Aluminum Discs

- Applications of 1100 Aluminum Discs and Examples

- Disadvantages of 1100 Aluminum Discs

- Comparative Analysis of 1100 Aluminum Discs with Other Alloys

- When to Choose 1100 Aluminum Discs

- Hot Topics about 1100 Aluminum Discs and Related Searches

- Conclusion

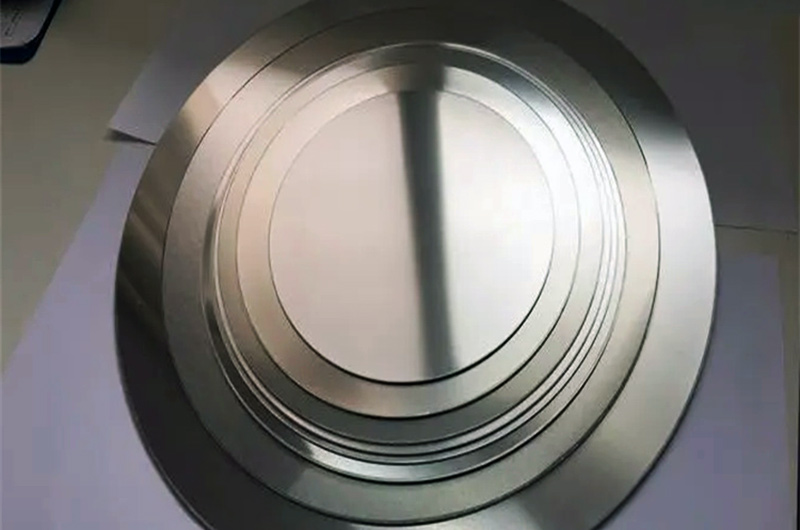

1100 aluminum discs, often referred to as aluminum circles, are essential components widely used across industries due to their remarkable properties. These discs are manufactured from high-purity aluminum alloy 1100, known for its excellent corrosion resistance, electrical conductivity, and formability.

Alloy 1100 aluminum discs have deep drawing quality, good spinning quality, excellent molding and anodizing, no four ears, and are mostly used in drawing, spinning and other processes.

Basic Information about 1100 Aluminum Discs

1100 Aluminum Disc Circle Composition

1100 aluminum discs are crafted from aluminum alloy 1100, which consists of a minimum of 99% pure aluminum. This high purity contributes to the alloy's excellent corrosion resistance and formability.

- Excellent reflectivity, conducive to polishing.

- The anodizing quality is good and suitable for hard anodizing and enamelling.

- The surface is smooth, the edges are smooth, hot-rolled quality, the grains are fine, and there are no loopers after deep drawing.

Key Properties of 1100 Aluminum Disc Circle

- Outstanding Corrosion Resistance: One of the most prominent features of 1100 aluminum discs is their exceptional resistance to corrosion, making them suitable for various environments and applications.

- Excellent Formability: These discs exhibit high formability and are easily stamped, bent, or machined into various shapes, making them versatile for customization.

- Electrical Conductivity: 1100 aluminum is an excellent electrical conductor, making it an ideal choice for electrical applications.

- Softness: The 1100 alloy is relatively soft, which aids in its formability but can lead to easy deformation and denting upon physical impact.

Performance of 1100 Aluminum Discs

1100 Aluminum Discs Mechanical Properties

- Tensile Strength: The tensile strength of 1100 aluminum discs typically ranges from 103 to 165 MPa, depending on the temper and thickness of the disc.

- Yield Strength: The yield strength is generally around 34 to 110 MPa. This value varies based on the temper and thickness of the discs.

- Elongation: The percentage of elongation for 1100 aluminum discs ranges from 25% to 35%, depending on the temper and specific alloy composition.

- Hardness: The hardness of 1100 aluminum discs is typically in the range of 23 to 34 Brinell, again influenced by the temper and thickness.

1100 Aluminum Discs Physical Properties

- Density: The density of 1100 aluminum is approximately 0.098 pounds per cubic inch (2.71 g/cm³).

- Melting Point: 1100 aluminum has a melting point of about 1, 221°F (660.3°C).

- Thermal Conductivity: The thermal conductivity of 1100 aluminum is around 229 W/m·K.

- Electrical Conductivity: 1100 aluminum exhibits excellent electrical conductivity, with a conductivity rating of approximately 62% IACS (International Annealed Copper Standard).

1100 Aluminum Discs Common Tempers

- 1100 O Aluminum Disc Circle

- 1100 H12 Aluminum Disc Circle

- 1100 H14 Aluminum Disc Circle

- 1100 H16 Aluminum Disc Circle

- 1100 H18 Aluminum Disc Circle

- O (Annealed): This temper represents fully annealed 1100 aluminum, which is soft and highly formable.

- H12: This temper indicates strain-hardened 1100 aluminum with low strength and improved formability.

- H14: Strain-hardened to a slightly higher level than H12, H14 temper provides better mechanical properties.

- H16: A higher level of strain hardening compared to H14, H16 offers improved strength and formability.

- H18: The highest level of strain hardening among the common tempers, H18 provides the best combination of strength and formability.

| TEMPER | THINCKNESS mm | TENSILE STRENGTH Mpa | ELONGATION % |

|---|---|---|---|

| O(SOFT) | 0.5-10 | 60-100 | ≥20 |

| H12 | 0.5-10 | 70-120 | ≥4 |

| H24 | 0.5-10 | 85-120 | ≥2 |

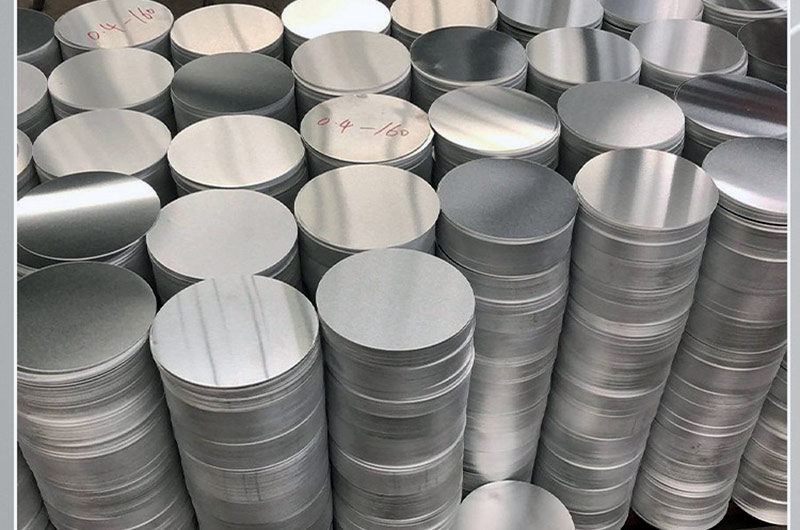

1100 Aluminum Discs Common Specifications

1100 aluminum discs are available in complete specifications. In addition to regular sizes, there are also platters as thin as 0.2mm and as thick as 6.5mm.

When the circle thickness is greater than 0.5mm, ensure that the edges of the finished product are neat and burr-free.

- ASTM B209: ASTM B209 is a standard specification for aluminum and aluminum-alloy sheet and plate, which covers 1100 aluminum discs and other alloys.

- AMS 4001: This is a specification that covers 1100 aluminum in various product forms, including circles and discs.

- QQ-A-250/1: QQ-A-250/1 is a federal specification for 1100 aluminum, which includes various forms and tempers.

- ISO 209: ISO 209 is an international standard specifying the mechanical and physical properties of 1100 aluminum.

- MIL-A-20731: This military specification covers the requirements for 1100 aluminum alloy in various forms, including discs.

Please note that specific requirements for 1100 aluminum discs may vary based on the intended application, so it's essential to consult the relevant standards and specifications for precise details in your particular use case.

1100 Aluminum Disc Quality

Haomei Aluminum strictly controls the quality of the aluminum discs, and has good control over the particle size grade and elongation of the coils in the early stage, ensuring the excellent drawing and spinning properties of the round materials and effectively avoiding the possibility of post-processing.

As the main supplier of aluminum wafers, Haomei Aluminum uses pure aluminum. The wafers are completely free of white rust, oil spots, roll marks, edge damage, bends, dents, holes, breaks, scratches and other defects.

The surface of the finished product made of aluminum discs is smooth and bright, without burrs or flash edges. Aluminum discs are known for their stable performance and high cost performance.

Advantages of 1100 Aluminum Discs

1. Outstanding Corrosion Resistance

The remarkable corrosion resistance of 1100 aluminum discs makes them an excellent choice for applications in various environments, including those exposed to moisture, chemicals, and harsh weather conditions.

2. High Formability

The high formability of 1100 aluminum discs allows for easy customization, making them suitable for applications that require precision and unique shapes.

3. Excellent Electrical Conductivity

In electrical and electronic applications, the excellent electrical conductivity of 1100 aluminum is a major advantage, ensuring efficient current flow.

4. Versatility

1100 aluminum discs are versatile and can be used in a wide range of industries, including cookware, signage, electronics, and more.

Applications of 1100 Aluminum Discs and Examples

1100 aluminum discs are used in cookware and engineering such as cookware, lighting purposes, cookware, frying pans, pots, kettles, lamp reflectors, etc.

1100 Aluminum Disc Circle for Cookware

1100 aluminum discs are frequently used in the manufacture of cookware, such as frying pans and pots. Their excellent corrosion resistance and formability ensure even heat distribution and efficient cooking.

1100 Aluminum Disc Circle for Signage

In the sign industry, 1100 aluminum discs are utilized for creating durable and weather-resistant signage. The corrosion-resistant nature of the alloy ensures long-lasting outdoor performance.

1100 Aluminum Disc Circle for Electrical Components

1100 aluminum discs are ideal for electrical applications due to their exceptional electrical conductivity. They are used in the manufacturing of components like electrical enclosures and connectors.

1100 Aluminum Disc Circle for Lamp Shades

The formability and softness of 1100 aluminum make it a popular choice for lamp shades and lighting fixtures, where precise shaping and aesthetics are essential.

Disadvantages of 1100 Aluminum Discs

1. Limited Strength

One of the primary disadvantages of 1100 aluminum discs is their limited strength. They may not be suitable for applications that require high structural integrity or load-bearing capacity.

2. Softness

The softness of 1100 aluminum discs makes them prone to deformation and denting upon physical impact, which may limit their use in applications with rigorous mechanical demands.

Comparative Analysis of 1100 Aluminum Discs with Other Alloys

1. 1050 Aluminum Discs

Compared to 1050 aluminum discs, which have similar properties, 1100 discs may offer slightly better corrosion resistance. Both alloys are highly formable and are suitable for a wide range of applications.

2. 3003 Aluminum Discs

3003 aluminum discs offer improved strength and can be an alternative to 1100 discs in applications where structural integrity is essential. However, 3003 may not match 1100 in terms of formability.

3. 6061 Aluminum Discs

6061 aluminum discs provide enhanced strength and are commonly used in applications requiring structural support. However, they may not be as easily formable as 1100 discs.

When to Choose 1100 Aluminum Discs

1. Corrosive Environments

When an application is exposed to corrosive environments or substances, 1100 aluminum discs are an excellent choice due to their outstanding corrosion resistance.

2. Custom Shaped Parts

For applications that require custom-shaped parts or precise components, 1100 aluminum discs are ideal due to their exceptional formability and versatility.

3. Electrical and Electronic Applications

In applications where electrical conductivity is crucial, such as electrical enclosures, connectors, and electronic components, 1100 aluminum discs offer excellent performance.

Hot Topics about 1100 Aluminum Discs and Related Searches

1. Hot Topics

"Corrosion Resistance of 1100 Aluminum Discs"

"Applications of 1100 Aluminum Discs in the Sign Industry"

"Custom Shaped Components with 1100 Aluminum Discs"

"Electrical and Electronic Applications of 1100 Aluminum Discs"

2. Related Searches

"1100 vs. 1050 Aluminum Discs"

"1100 vs. 3003 Aluminum Discs"

"1100 vs. 6061 Aluminum Discs"

"1100 Aluminum Discs for Cookware"

"1100 Aluminum Discs for Lamp Shades"

Conclusion

1100 aluminum discs, with their exceptional corrosion resistance, formability, and electrical conductivity, find applications in various industries, including cookware, signage, and electrical components.

While they offer unique advantages, it's essential to consider their limitations, such as limited strength and softness.

When choosing 1100 aluminum discs, it's crucial to evaluate the specific requirements of your application and ensure they align with the alloy's properties.

The versatility and reliability of 1100 aluminum discs make them an excellent choice for various environments and industries. By understanding their strengths, weaknesses, and potential challenges, you can make well-informed decisions and harness the full potential of this versatile material.