- What is 1060 Aluminum Foil?

- What are the Key Properties of 1060 Aluminum Foil?

- Advantages of 1060 aluminum foil

- 1060 Aluminum Foil Specifications

- Mechanical Properties of 1060 Aluminum

- Chemical Composition of 1060 Aluminum

- 1060 Aluminum Foil Applications

- Frequently Asked Questions about the 1060 Aluminum Foil

What is 1060 Aluminum Foil?

1060 aluminum foil is a type of industrial aluminum foil. The purity of aluminum is 99.6%, so it retains the excellent ductility, corrosion resistance, electrical conductivity, thermal conductivity, moisture resistance, and formability of pure aluminum.

- 1060 aluminum foil can be used for perfect sealing of pharmaceutical injections due to its excellent tensile properties.

- 1060 battery aluminum foil has good conductivity and can effectively improve the performance of lithium-ion batteries.

- 1060 aluminum foil has amazing thermal conductivity and is a good choice for lunch box materials and more.

- 1060 aluminum foil 0.1mm thick hot-rolled materials are widely used in the auto parts industry.

1060 aluminum foil adds a small amount of copper elements and has many excellent properties. 1060 aluminum foil adopts heat treatment process to ensure that the performance, thickness tolerance and surface quality of 1060 aluminum foil meet the requirements.

1060 aluminum foil is a soft and malleable material that can be easily made into various shapes and sizes. It can be processed by rolling, annealing, slitting, etc. to achieve different thicknesses and widths. It has a smooth surface finish and is available in tempers such as O (annealed), H14 (semi-hard), H18 (full-hard) and H24 (semi-hard).

What are the Key Properties of 1060 Aluminum Foil?

1060 aluminum foil has high electrical conductivity, excellent corrosion resistance, good workability, and is highly reflective. These properties make it suitable for various applications.

- 1060 aluminum foil has low strength and poor cutting processability.

- 1060 aluminum foil has good welding performance and can be gas welded, hydrogen welded and contact welded, but it is not easy to braze.

- 1060 aluminum foil is easy to withstand various pressure processing, stretching and bending.

Advantages of 1060 aluminum foil

- 1. The layout is smooth, and the foil produced has no defects such as black spots, scratches, bright lines, and roller printing.

- 2. 1060 aluminum foil has the advantages of non-toxic, corrosion-resistant, moisture-proof, and high-temperature sterilizability.

- 3. High conductivity. Compared with other aluminum alloy foils, 1060 aluminum foil has strong conductive advantages. Likewise, its thermal and electrical conductivity is second only to copper, silver, and gold.

- 4. Excellent formability. 1060 aluminum foil has good elongation and processing performance, strong plasticity, moderate tensile strength, and can well meet conventional processing requirements (such as stamping, stretching, etc.)

- 5. High stability. 1060 aluminum foil can withstand high and low temperatures (-20℃ to +250℃) without changing its properties.

- 6. 1060 aluminum foil also has good light shielding, insulation and corrosion resistance, and the anodizing surface treatment effect is obvious.

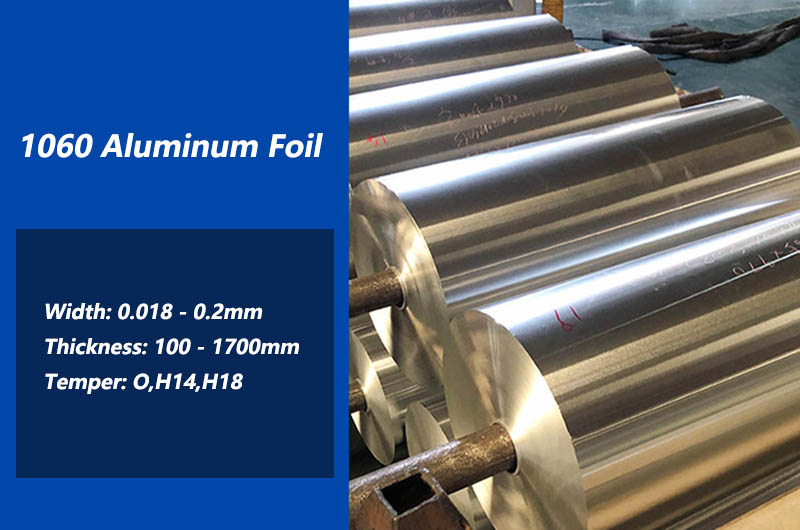

1060 Aluminum Foil Specifications

Haomei Aluminum strictly controls the structure, performance, plate shape, thickness difference, and surface quality requirements of 1060 aluminum foil to ensure the production of high-quality 1060 aluminum foil.

| Typical Alloy | 1060 Aluminum Foil |

|---|---|

| Temper | O, H18, H22, H24 |

| Thickness(mm) | 0.018-0.2 |

| Widthness(mm) | 100-1600 |

| Length(mm) | C |

| Typical Products | Cap material, Food packaging, Aluminum foil gaskets, Electronic labels, etc |

| Surface Protection | Paper interleaved, PE/PVC filming |

| Surface Finish | Mill Finish, color coated, stucco embossed, etc |

| Standard | GB/T, ASTM, EN standard qualified |

| Thickness Range | Application Fields | Specific Examples of Application |

|---|---|---|

| 0.006mm - 0.2mm | Food packaging, pharmaceutical packaging, and other light packaging industries | Beverage packaging, candy packaging, cheese packaging, jam packaging, cigarette packaging, pharmaceutical packaging, cosmetic packaging, etc. |

| 0.2mm - 0.5mm | Decoration materials, building materials, and light industry | Roof insulation materials, cable sheaths, sound insulation boards, thin-walled containers, aircraft aviation materials, etc. |

| > 0.5mm | Power electronics, chemical industry, and aerospace industry | Battery materials, photovoltaic solar panels, transformer materials, aircraft components, etc. |

The specifications of 1060 aluminum foil depend on the requirements of thickness and width, usually the thickness is 0.006mm - 0.2mm, and the width is 100mm - 1600mm. In addition, 1060 aluminum foil can also be customized into rolls or flat sheets according to different application requirements to meet different packaging and processing needs.

Mechanical Properties of 1060 Aluminum

| Property | Value |

|---|---|

| Tensile Strength | 65-95 MPa |

| Yield Strength | 20-50 MPa |

| Elongation | 25-35% |

| Hardness | 19-23 HB |

Chemical Composition of 1060 Aluminum

| Element | Composition (%) |

|---|---|

| Aluminum | 99.60 |

| Silicon | 0.25 |

| Iron | 0.35 |

| Copper | 0.05 |

| Magnesium | 0.03 |

| Manganese | 0.03 |

| Zinc | 0.05 |

| Titanium | 0.03 |

| Others | 0.03 |

1060 Aluminum Foil Applications

1060 industrial pure aluminum foil is widely used in the manufacture of PCB covers, aluminum foil gaskets, auto parts, capacitors, lunch box materials, food packaging and electronic labels due to its high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. .

1060 Aluminum Foil for Food Packaging

1060 aluminum foil can be easily folded, cut and packaged to suit different types of food packaging requirements.

- Advantages : With good barrier properties, it can effectively protect food from oxygen, moisture and odor.

- State : O (softened)

- Thickness : 0.006mm - 0.2mm

- Width : 100mm - 1600mm

1060 Aluminum Foil Pharmaceutical

1060 Aluminum Foil Pharmaceutical complies with hygienic standards and relevant regulations on pharmaceutical packaging to ensure its safety and reliability.

- Advantages : Good formability, can be customized according to different requirements of pharmaceutical packaging, for example, made into capsule packaging or pharmaceutical stick packaging.

- State : O (softened)

- Thickness : 0.02mm - 0.2mm

- Width : 100mm - 1000mm

1060 Electronic Aluminum Foil

The high electrical conductivity and good chemical stability of 1060 aluminum foil make it an important material in the manufacture of electronic products.

- Advantage : Excellent conductivity and stability

- State : H18 (full hard)

- Thickness : 0.01mm - 0.2mm

- Width : 100mm - 1000mm

1060 Aluminum Foil Lithium Battery

1060 H18 aluminum foil can greatly ensure smooth conduction and reduce the contact resistance between positive and negative electrode materials and current collectors. It results in a significant improvement in the overall performance of the battery.

1060 Aluminum Foil for Battery Soft Connection

1060 aluminum foil has the characteristics of high conductivity, large carrying capacity, good weldability, light weight, non-magnetic, fast heat dissipation, etc. Poor electrical conductivity of the battery pack caused by loose firmware.

Transformer 1060 Aluminum Foil

1060 aluminum foil is a commonly used material for manufacturing transformer windings, and its performance directly affects the quality of the transformer. 1060 aluminum foil is lightweight, thermally conductive, and has good formability, protection, safety, and circulation. It is currently a widely used transformer winding material.

1060 Aluminum Foil for New Energy Vehicle Batteries

In new energy vehicles, a large number of lithium battery packs are required to be connected together to provide energy. Taking into account lightweight and heat dissipation performance, the battery pack connections are made of 1060 aluminum foil.

1060 Aluminum Foil for Automotive Heat Shield

1060 aluminum foil is a commonly used automotive heat shield material. 1060-o aluminum foil is soft in texture and has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. Recycle.

1060 Aluminum Foil for Perfume Bottle Cap Material

There are many kinds of perfumes. If you want to keep the perfume for a longer time, you have strict requirements on the sealing of the bottle cap material. The perfume bottle cap material is commonly used 1060 aluminum foil, 8011 aluminum foil and so on.

1060 aluminum foil is used in decorative materials and industrial applications in various specifications and states, and is usually customized according to specific requirements. For example, 1060 aluminum foil used in automobile parts and building materials usually needs to have good strength and corrosion resistance, so it will adopt H14 (semi-hard) or H18 (full-hard) state, and make different specifications and sizes according to different requirements . Capacitors, aluminum foil gaskets, aluminum gaskets such as electronic tags, electrolytic capacitors, and automotive heat shields.

Frequently Asked Questions about the 1060 Aluminum Foil

Is 1060 Aluminum Foil Food-safe?

Yes, 1060 aluminum foil is food-safe and commonly used for wrapping and preserving food. It is non-toxic and does not react with acidic or alkaline foods.

Is 1060 Aluminum Foil Easy to Work With?

Yes, 1060 aluminum foil is known for its good workability. It can be easily formed, folded, and shaped without breaking or cracking. This makes it suitable for various manufacturing processes.

Does 1060 Aluminum Foil Have any Special Surface Treatments or Coatings?

Depending on the specific application, 1060 aluminum foil may have different surface treatments or coatings to enhance its performance, such as lubricants for easy release during rolling or coatings to improve heat resistance.

Is 1060 Aluminum Foil Recyclable?

Yes, aluminum, including 1060 aluminum foil, is highly recyclable. Recycling aluminum consumes significantly less energy compared to producing it from raw materials, making it an environmentally friendly option.

Can 1060 Aluminum Foil be used for Insulation?

Yes, 1060 aluminum foil is often used in the production of insulation materials due to its reflective properties. It helps to reflect heat away from surfaces, making it useful in insulation applications.

What are the Considerations when Choosing 1060 Aluminum Foil for a Specific Application?

When selecting 1060 aluminum foil, consider factors such as the required thickness, surface treatments, and coatings, as well as the specific properties needed for your application, such as electrical conductivity, corrosion resistance, and heat reflectivity.