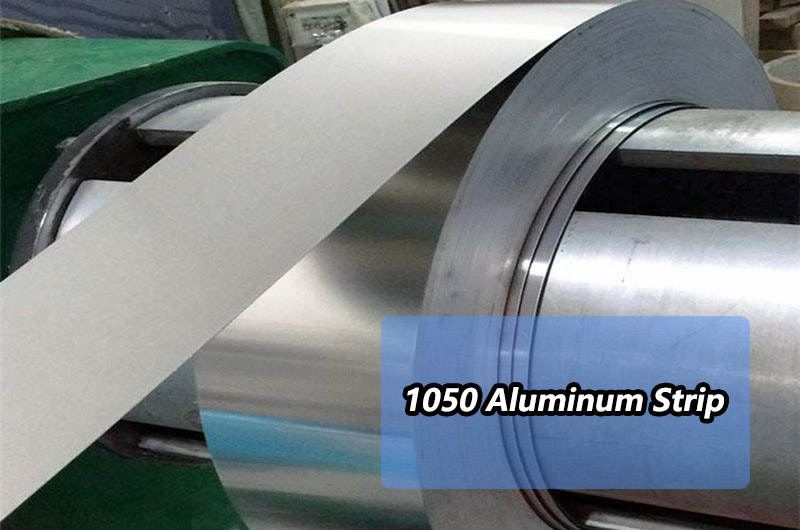

- 1050 Aluminum Strip Features

- 1050 Aluminum Strip Parameters

- Performance of 1050 Aluminum Strips

- Tolerances for 1050 Aluminum strips

- Mechanical Properties of 1050 Aluminum Strip

- 1050 Aluminum Strip Uses

- 1050 Aluminum Properties

- Chemical Composition of 1050 Aluminum

1050 aluminum strip is a pure aluminum strip with an aluminum content of more than 99.5%. It has high electrical conductivity, excellent formability, and good corrosion resistance, and is used in electrical and electronic components, transformers, busbars, and heat exchangers, etc.

With years of production experience, Haomei Aluminum specializes in producing a variety of high-quality aluminum strips, among which the hot-selling aluminum strips include:

- 1050 Aluminum Strip

- 1060 Aluminum Strip

- 1070 Aluminum Strip

- 1100 Aluminum Strip

- 3003 Aluminum Strip

- 5052 Aluminum Strip

- 3004 Aluminum Strip

- 5005 Aluminum Strip

1050 Aluminum Strip Features

- Good softness : 1050 aluminum strip is a kind of soft aluminum strip, which is easy to process and form.

- Good electrical performance : 1050 aluminum strip has good electrical and thermal conductivity, and is often used in electronic components and circuit boards and other fields.

- Good corrosion resistance : excellent corrosion resistance and is suitable for use in various environments and conditions.

- Easy to clean and maintain : 1050 aluminum strip has a smooth surface, easy to wipe and maintain.

- Strong machinability : 1050 aluminum strip is easy to form, cut and weld, and can be used in a variety of manufacturing processes.

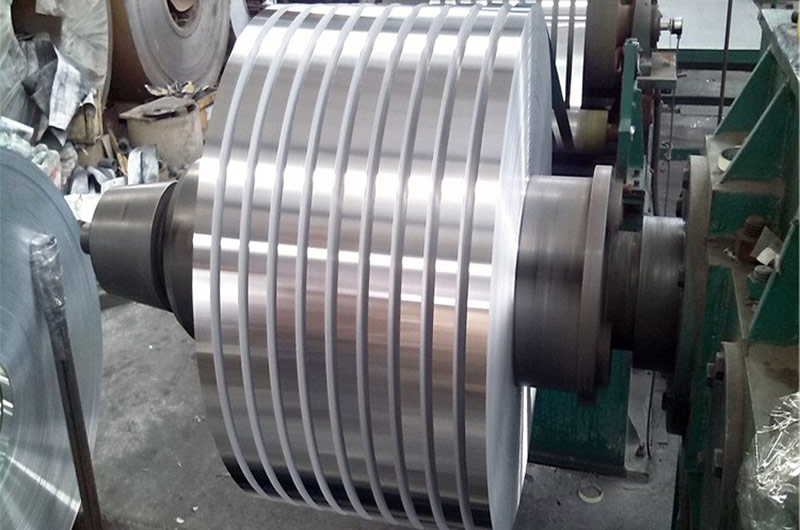

1050 Aluminum Strip Parameters

- Aluminum Purity: 99.95%

- Temperament: O, H14, H24

- Thickness: 0.1mm~3mm

- Width: 15mm~1400mm

- Quantity tolerance: ±10%

- ID: 152.4, 200, 305, 405 and 505mm, costmized

- Surface treatment: polished surface

- Performance: smooth surface, no burrs, chamfered on both sides, high conductivity

- Sample: Provide aluminum strip samples

- Packing: paper + plastic film + woven bag + paper angel beads + wooden box

Performance of 1050 Aluminum Strips

1050 Aluminum Strips Electrical Conductivity

| Aluminum Strip | Electrical Conductivity |

|---|---|

| 1050 O aluminum strip | approximately 62% IACS |

| 1050 H12 aluminum strip | approximately 61% IACS |

| 1050 H14 aluminum strip | approximately 60% IACS |

| 1050 H16 aluminum strip | approximately 59% IACS |

| 1050 H18 aluminum strip | approximately 58% IACS |

1050 Aluminum Strips Thermal Conductivity

| Aluminum Strip | Thermal Conductivity |

|---|---|

| 1050 O aluminum strip | approximately 230 W/mK |

| 1050 H12 aluminum strip | approximately 210 W/mK |

| 1050 H14 aluminum strip | approximately 190 W/mK |

| 1050 H16 aluminum strip | approximately 170 W/mK |

| 1050 H18 aluminum strip | approximately 150 W/mK |

Tolerances for 1050 Aluminum strips

Tolerances for 1050 aluminum strip depend on the thickness and width of the material, as well as the specific requirements of the application.

- Thickness Tolerance : 1050 aluminum strip typically has a thickness tolerance of +/-0.005mm to +/-0.15mm, depending on the thickness of the material.

- Width Tolerance : 1050 aluminum strip typically has a width tolerance of +/-0.1mm to +/-2mm, depending on the width of the material.

- Length Tolerance : 1050 aluminum strip typically has a length tolerance of +/-0.5mm to +/-10mm, depending on the length of the material.

- Flatness tolerance : The flatness tolerance of 1050 aluminum strip is usually measured with a bow gauge, and the allowable deviation depends on the thickness and width of the material.

When ordering 1050 aluminum strip, the required tolerance must be specified to ensure the material meets the necessary specifications.

Mechanical Properties of 1050 Aluminum Strip

| 1050 aluminum strip | Thickness(mm) | Tensile Strength(Mpa) | The Yield Strength(Mpa) | elongation(%) | hardness(HV) |

|---|---|---|---|---|---|

| 1050 O | >0.2-0.5 | 60-100 | ≥15 | ≥20 | 20-30 |

| 1050 O | >0.5-1.0 | ≥30 | |||

| 1050 O | >1.0-4.0 | ≥35 | |||

| 1050 H22 | >0.2-0.5 | 80-120 | ≥60 | ≥12 | 30-40 |

| 1050 H22 | >0.5-1.0 | ≥15 | |||

| 1050 H22 | >1.0-4.0 | ≥18 | |||

| 1050 H24 | >0.2-0.5 | 95-135 | ≥70 | ≥6 | 35-45 |

| 1050 H24 | >0.5-1.0 | ≥8 | |||

| 1050 H24 | >1.0-4.0 | ≥10 | |||

| 1050 H26 | >0.2-0.5 | 110-155 | ≥75 | ≥2 | 43-55 |

| 1050 H26 | >0.5-1.0 | ≥4 | |||

| 1050 H26 | >1.0-4.0 | ≥6 | |||

| 1050 H18 | >0.2-0.5 | ≥125 | ≥85 | ≥2 | 50-65 |

| 1050 H18 | >0.5-1.0 | ≥3 | |||

| 1050 H18 | >1.0-4.0 | ≥4 |

1050 Aluminum Strip Uses

1050 aluminum strips are often used in daily necessities, lighting fixtures, reflective panels, decorations, chemical industry containers, heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stamping parts and other products. In some situations where high corrosion resistance and formability are required, but strength is not required, chemical equipment is a typical use.

1050 Aluminum Strip for Transformer Winding

1050 aluminum strip is a popular choice for transformer windings due to its excellent electrical and thermal conductivity. The conductivity of 1050 aluminum strip is about 62% IACS, which is higher than that of copper and is an excellent electrical conductor. Additionally, 1050 aluminum strip has excellent thermal conductivity for efficient heat dissipation in transformer winding applications.

1050 Aluminum strip for transformer winding is also very light weight, which is beneficial for transformer applications where weight reduction is required. In addition, 1050 aluminum strip has good corrosion resistance, which can prolong the service life of transformer windings.

1050 aluminum strip is an excellent choice for transformer windings due to its high electrical and thermal conductivity, formability, light weight and corrosion resistance.

1050 Aluminum Strip for Electrode Foil

1050 aluminum strip is widely used in the manufacture of electrolytic capacitors as electrode foil material. An electrolytic capacitor is a common electronic component used for electrical energy storage, filtering, coupling, and more.

Aluminum strips for capacitors require high surface finish and no impurities such as oil stains and oxide skins to ensure stable and reliable performance of capacitors.

- Alloy : 1050A-O alloy

- Thickness : 0.08mm

- Width : 60mm

1050 Aluminum Strip for Condenser

Aluminum strips used in condensers are typically made from 1050 aluminum alloy, which has high electrical conductivity and excellent formability.

1050 aluminum strip is ideal for a variety of condenser applications due to its corrosion resistance, thermal conductivity and low density, yet is lightweight and durable.

- Alloy : 1050-H24

- Thickness : 0.15mm

- Width : 500mm

Used in the manufacture of condensers in household appliances such as refrigerators and air conditioners, refrigeration systems and car radiators.

1050 Aluminum Composite Panel

1050 Aluminum Composite Panel (ACP) is a sandwich panel made of two aluminum panels bonded to a core material. The core material can be made of various materials such as polyethylene, polyurethane or refractory mineral core.

- Alloy : 1050A-H14

- Thickness : 0.3-0.5mm

- Width : 800mm

It is used in the manufacture of building decoration materials such as interior walls and billboards.

1050 ACP is widely used in the construction industry for its beauty and durability. It is commonly used in building cladding, signage and interior decoration. Available in a variety of colours, finishes and sizes, these panels allow architects and designers to create custom designs to suit their project requirements.

1050 Aluminum Properties

- Strength : 1050 aluminum has low strength and is not suitable for applications requiring high strength or hardness.

- Corrosion resistance : 1050 aluminum has good corrosion resistance, especially in atmospheric environments.

- Weldability : 1050 aluminum is easily welded using a variety of welding methods, including TIG, MIG, and resistance welding.

- Formability : 1050 aluminum has excellent formability and can be easily formed into various shapes using standard metalworking equipment.

- Surface finish : 1050 aluminum has a bright, reflective surface that can be polished to a mirror-like finish.

| Property | Value |

|---|---|

| Density | 2.71 g/cm3 |

| Melting Point | 655°C |

| Thermal Conductivity | 229 W/m-K |

| Electrical Conductivity | 63% IACS |

| Coefficient of Thermal Expansion | 23.5 × 10^-6/K |

Chemical Composition of 1050 Aluminum

| Element | Percentage (%) |

|---|---|

| Al | 99.50 or more |

| Si | 0.25 max |

| Fe | 0.40 max |

| Cu | 0.05 max |

| Mg | 0.05 max |

| Mn | 0.05 max |

| Zn | 0.05 max |

| Ti | 0.03 max |

| Other | 0.15 max |