- What is Aluminum Plate 1050 grade?

- 1050 Aluminum Plate Informations

- 1050 Aluminum Plate Specifications

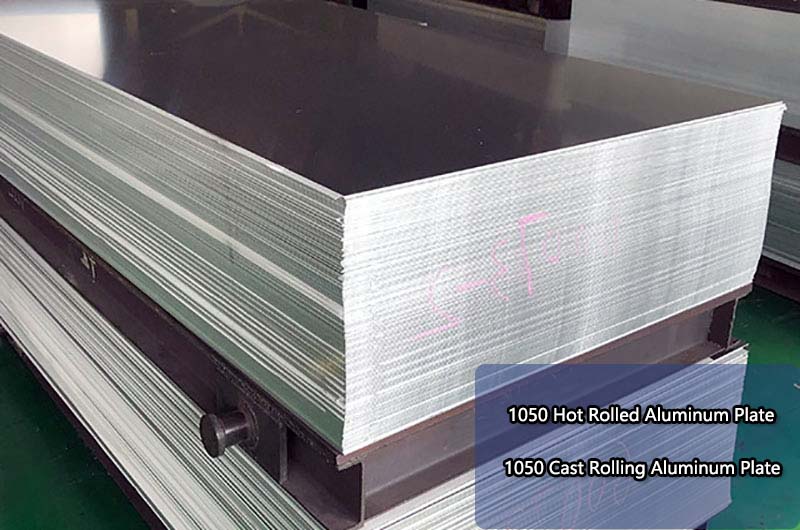

- Typical 1050 Aluminum Plate

- Aluminum 1050 Data Plate

- What is 1050 Aluminum Plate Used for?

- What is the Price of Aluminum 1050 Plate?

- What is the Difference between Aluminum 1050 and 1200?

What is Aluminum Plate 1050 grade?

1050 aluminum alloy Due to its high purity, 1050 aluminum plate has excellent electrical conductivity, thermal conductivity and corrosion resistance. It is also very malleable and has good workability, making it easy to form and form.

1050 aluminum plate is commonly used in applications such as chemical and food processing equipment, decorative and reflective surfaces, and electrical and electronic components. It can also be used for general sheet metal fabrication, as well as building and construction applications such as roofing, cladding and facades.

1050 Aluminum Plate Informations

| Process | Rating |

| Workability - Cold | Excellent |

| Machinability | Poor |

| Weldability - Gas | Excellent |

| Weldability - Arc | Excellent |

| Weldability - Resistance | Excellent |

| Brazability | Excellent |

| Solderability | Excellent |

1050 Aluminum Plate Specifications

Typical Dimensions

- Thickness : 0.2mm - 300mm

- Width : up to 2600mm

- Length : up to 12000mm

| Alloy Temper | Thickness/Width/Length mm |

|---|---|

| 1050 H24 Aluminum Plate | 3.9*1220*2440 |

| 1050 H18 Aluminum Plate | 0.23*820*710 |

| 1050 H24 Aluminum Plate | 1.17*1220*2440 |

| 1050 Cast Rolling Aluminum Plate | |

| 1050 H14 Aluminum Plate | 5*1070*2424 |

| 1050 H14 Aluminum Plate | 5*1134*2348 |

Equivalent 1050

- EN AW-1050A (Al99.5(A))

- ISO Al99.5

- AA 1050A

- UNS A91050

- AA 1050

- AL 1050

Standard Specifications

- ASTM B209 : Standard Specification for Aluminum and Aluminum Alloy Sheet and Plate

- EN 485-1 : Aluminum and aluminum alloys - Plate, strip and plate - Part 1 : Specifications for inspection and delivery

- ISO 6361-2 : Wrought aluminum and aluminum alloys - Plate, strip and plate - Part 2 : Mechanical properties

Typical 1050 Aluminum Plate

1050a H24 Aluminum Plate

Aluminum 1050 H24 This is a cold worked and partially annealed temper that provides higher strength and better formability compared to annealed (O) tempers.

- Characteristics : The tensile strength of Aluminum 1050 H24 is slightly higher than that of H14 and H16 states, and it has higher strength and better formability than the annealed state.

- Applications : The H24 temper is typically used in applications requiring moderate strength and good formability, such as roofing and construction, and chemical and food processing equipment.

1050 H18 Aluminum Plate

Aluminum 1050 H18 is the strongest primary temper of 1050 aluminum plate, it is used in applications requiring high strength and durability.

- Features : 1050 aluminum plate is tempered with the highest strength, and has excellent resistance to corrosion and surface damage.

- Applications : For applications requiring high strength and durability such as truck bodies, refrigeration units and chemical processing equipment.

1050 H14 Aluminum Plate

A1050 h14 is a slightly harder and stronger temper than H12, it is usually used for general sheet metal working.

- Features : A1050 h14 is slightly harder and stronger than H12, with higher dent and scratch resistance.

- Applications : General roofing and construction, chemical and food processing equipment and appliances.

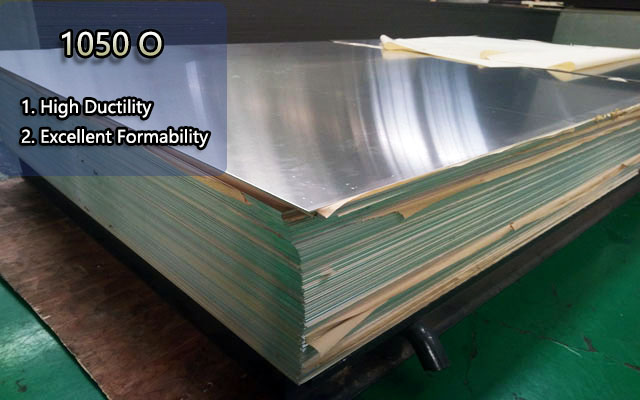

1050 O Aluminum Plate

O is the softest state of 1050 aluminum sheet, it is used for deep drawing, spinning and other applications that require a lot of forming.

- Features : high ductility, excellent formability, low strength and hardness.

- Applications : Commonly used in kitchenware, chemical and food processing equipment, and decorative parts.

1050 H12 Aluminum Plate

H12 is a cold worked and strain hardening temper that provides slightly higher strength and improved formability.

- Characteristics : Compared with the annealed state, the strength is slightly higher and the formability is improved.

- Applications : Commonly used in applications such as kitchenware, reflectors and decorative parts.

1050 H16 Aluminum Plate

The H16 temper has higher strength and higher corrosion resistance.

- Properties : Harder, easier to form, higher strength and higher corrosion resistance than H14.

- Applications : For applications such as reflectors, signs and lighting.

- O is the softest and most formable.

- H18 temper provides the highest strength and durability.

- H12 and H14 tempers provide a balance of strength and formability.

- The H16 temper provides improved corrosion resistance.

- The H24 temper offers higher strength and formability than the annealed condition, but not as strong as some of the harder tempers.

Aluminum 1050 Data Plate

1050 Aluminum Plate Chemical Composition

| Element | % Present |

| Manganese (Mn) | 0.0 - 0.05 |

| Iron (Fe) | 0.0 - 0.40 |

| Copper (Cu) | 0.0 - 0.05 |

| Magnesium (Mg) | 0.0 - 0.05 |

| Silicon (Si) | 0.0 - 0.25 |

| Zinc (Zn) | 0.0 - 0.07 |

| Titanium (Ti) | 0.0 - 0.05 |

| Aluminium (Al) | Balance |

1050 Aluminum Plate Physical Properties

| Physical Property | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 24 x 10-6/K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 222 W/m.K |

| Electrical Resistivity | 0.0282 x 10-6 Ω .m |

1050 Aluminum Plate Mechanical Properties

| Alloy Temper | Specified | Tensile strength | Yield strength | Elongation |

| Thickness(mm) | (MPa) | (MPa) | (%) | |

| 1050-O/ 1050-H111 | 0.2-0.5 | 65-95 | Min20 | Min20 |

| 0.5-1.5 | Min22 | |||

| 1.5-3.0 | Min26 | |||

| 3.0-6.0 | Min29 | |||

| 6.0-12.5 | Min35 | |||

| 12.5-80.0 | ||||

| 1050-H112 | 6.0-12.5 | Min75 | Min30 | Min20 |

| 12.5-80.0 | Min70 | Min25 | ||

| 1050-H12 | 0.2-0.5 | 85-125 | Min65 | Min2 |

| 0.5-1.5 | Min4 | |||

| 1.5-3.0 | Min5 | |||

| 3.0-6.0 | Min7 | |||

| 6.0-12.5 | Min9 | |||

| 12.5-40.0 | ||||

| 1050-H14 | 0.2-1.5 | 105-145 | Min85 | Min2 |

| 1.5-3.0 | Min4 | |||

| 3.0-6.0 | Min5 | |||

| 6.0-12.5 | Min6 | |||

| 12.5-25 | ||||

| 1050-H16 | 0.2-0.5 | 120-160 | Min100 | Min1 |

| 0.5-1.5 | Min2 | |||

| 1.5-4.0 | Min3 | |||

| 1050-H18 | 0.2-0.5 | Min135 | Min120 | Min1 |

| 0.5-1.5 | Min140 | Min2 | ||

| 1.5-3.0 | Min2 | |||

| 1050-H19 | 0.2-0.5 | Min155 | Min140 | Min1 |

| 0.5-1.5 | Min150 | Min130 | ||

| 1.5-3.0 | ||||

| 1050-H22 | 0.2-0.5 | 85-125 | Min55 | Min4 |

| 0.5-1.5 | Min5 | |||

| 1.5-3.0 | Min6 | |||

| 3.0-6.0 | Min11 | |||

| 6.0-12.5 | Min12 | |||

| 1050-H24 | 0.2-0.5 | 105-145 | Min75 | Min3 |

| 0.5-1.5 | Min4 | |||

| 1.5-3.0 | Min5 | |||

| 3.0-6.0 | Min8 | |||

| 6.0-12.5 | ||||

| 1050-H26 | 0.2-0.5 | 120-160 | Min90 | Min2 |

| 0.5-1.5 | Min3 | |||

| 1.5-4.0 | Min4 | |||

| 1050-H28 | 0.2-0.5 | Min140 | Min110 | Min2 |

| 0.5-1.5 | ||||

| 1.5-3.0 | Min3 |

Thermal Properties

| Property | Value |

|---|---|

| Coefficient of thermal expansion | 24.2 x 10^-6/K |

| Thermal conductivity | 230 W/m·K |

What is 1050 Aluminum Plate Used for?

AA 1050 Aluminum for Kitchenware and Cookware

1050 aluminum sheet is often used to make utensils, pots and pans and other kitchen utensils due to its excellent formability and corrosion resistance.

- Alloy : 1050A

- State : O (annealed) or H12

- Specifications : Typical thickness is 0.5-3.0 mm

- Application areas : Pots, pans, cutlery and other kitchen utensils

- Example : pan

- Reasons to use it : 1050A aluminum has excellent formability and corrosion resistance, making it ideal for kitchenware and cookware that requires extensive forming and exposure to corrosive environments.

Click to learn more aboutCookware Aluminum

1050 Aluminum for Chemical and Food Processing Equipment

The excellent corrosion resistance of 1050 aluminum makes it suitable for use in chemical and food processing equipment such as tanks, pipes and containers.

- Alloy : 1050

- Status : H14 or H24

- Specifications : Typical thickness is 1.0-6.0 mm

- Applied Parts : Tanks, Pipes and Vessels

- Example : Chemical Treatment Tank

- Why use it : 1050 aluminum has excellent corrosion resistance and can withstand exposure to aggressive chemicals and food.

1050 Aluminum for Roofing and Construction

The lightweight and corrosion-resistant properties of 1050 aluminum sheet make it a popular choice for roofing and construction applications such as gutters, downspouts, and shingles.

- Alloy : 1050

- Status : H14 or H24

- Specifications : Typical thickness is 0.5-3.0 mm

- Applied Parts : Gutters, Downspouts and Roof Slabs

- Example : roof panels

- Why you should use it : 1050 aluminum is light, corrosion-resistant, and formable, making it an ideal material for roofing and construction applications.

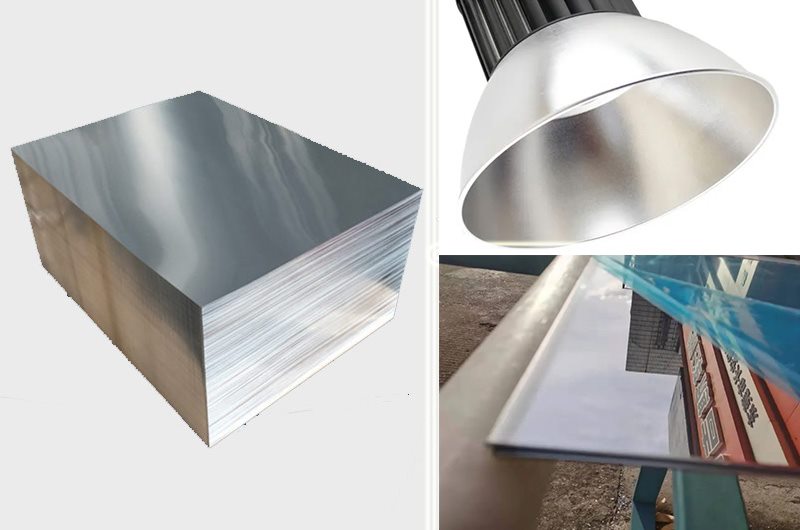

1050 Aluminum Reflectors and Lighting Fixtures

The high reflectivity and formability of 1050 aluminum make it suitable for use in reflectors and lighting fixtures.

- Alloy : 1050

- Temper : H16

- Specifications : Typical thickness is 0.25-2.0 mm

- Applied parts : reflectors, lighting fixtures

- Example : Light Reflector

- Why use it : 1050 aluminum is highly reflective and formable, making it ideal for use in reflectors and lighting fixtures.

Click to learn more aboutLighting Aluminum

Signage and Decorative Trim

The formability and aesthetics of 1050 aluminum make it a popular choice for signage, trim and other architectural applications.

- Alloy : 1050

- Status : H14 or H24

- Specifications : Typical thickness is 0.5-2.0 mm

- Application parts : signs, decorative strips

- Example : Architectural Decoration

- Reasons for use : 1050 aluminum has good formability and aesthetic appearance, and is an ideal material for architectural decoration and signage.

Electrical Components

The high thermal conductivity of 1050 aluminum makes it an ideal material for use in electrical components such as heat sinks and PCB substrates.

- Alloy : 1050

- State : O (annealed) or H14

- Specifications : Typical thickness is 0.5-3.0 mm

- Applied parts : heat sink, PCB substrate

- Example : Radiator

- Why you should use it : 1050 aluminum has high thermal conductivity, making it an ideal material for heat sinks and other electrical components that require efficient heat dissipation.

What is the Price of Aluminum 1050 Plate?

- Market price : The current market price of aluminum will affect the price of 1050 aluminum sheet. This may vary depending on supply and demand, global economic conditions and other market factors.

- Thickness and size : The thickness and size of the aluminum sheet can affect the price, as thicker and larger sheets may require more material and processing time, resulting in higher costs.

- Quantity : The quantity of 1050 aluminum sheet ordered will affect the price as suppliers may offer discounts for bulk orders.

- Surface Finish and Finish : The required surface finish and finish will also affect the price. For example, if the board needs to be polished or a specific surface treatment applied, this can add cost.

To calculate the price of 1050 aluminum sheet, you can contact the supplier and you may be asked to provide the thickness, size, quantity and other specifications of the sheet to generate an estimate.

What is the Difference between Aluminum 1050 and 1200?

Chemical Composition

- 1050 Aluminum has a minimum purity of 99.5% and contains trace amounts of other elements including iron, silicon and zinc.

- Aluminum 1200 has a minimum purity of 99.0% and also contains traces of iron and silicon.

Physical Properties

Both alloys have similar physical properties, including low density, high electrical conductivity and good thermal conductivity. 1200 is slightly stronger than 1050 though.

Applications

Aluminum 1050 and 1200 are commonly used in a range of applications including cookware, heat exchangers, lighting reflectors and signage. However, due to its higher strength, 1200 aluminum is often used in applications that require higher strength, such as aircraft parts and chemical equipment.