The surface of 1050 aluminum coil is smooth and smooth, without defects such as wrinkles, scale and oil stains. When processing and using, 1050 aluminum coil has good machinability and formability, and can be processed and formed by rolling, stretching, deep drawing, etc.

According to different application requirements, 1050 aluminum coils can be produced in different states, and the common states are H12, H14, H16 and H18. 1050 aluminum coils in different states are different in strength, hardness and ductility, and are suitable for different application scenarios.

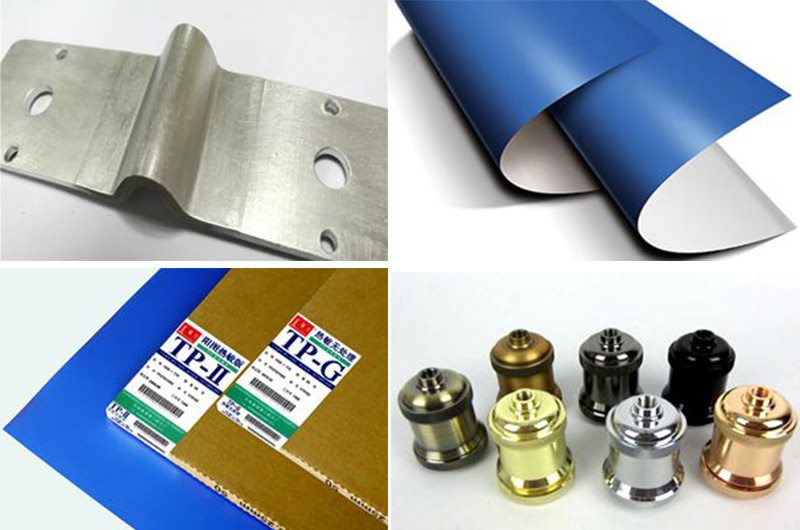

In addition to standard specifications, 1050 aluminum coils can be customized according to customers' specific requirements, such as special thickness, width, length, surface treatment, etc. Due to its good plasticity, corrosion resistance and electrical conductivity, 1050 aluminum coil is widely used in food packaging, electronics, chemical industry, construction, home appliances, aerospace and other fields.

1050 Aluminum Coil Specifications

- Thickness : The thickness of 1050 aluminum coils is generally between 0.1-6.0mm, and the common specifications are 0.2mm, 0.5mm, 1.0mm, etc.

- Width : The width of 1050 aluminum coils is generally between 1000-2000mm, and the common specifications are 1000mm, 1200mm, 1500mm, etc.

- Coil weight : The coil weight of 1050 aluminum coils is generally between 1-5 tons, depending on different factors such as thickness, width, and coil diameter.

- Coil diameter : The coil diameter of 1050 aluminum coil is generally between 300-800 mm, and the common specifications are 508 mm, 610 mm, etc.

The above specifications are not fixed and will vary according to the needs of customers. When purchasing 1050 aluminum coils, it is necessary to select the appropriate specifications and state according to the actual application to ensure the quality and use effect of the product.

Commonly used 1050 aluminum coil

1050 aluminum coils in different states are different in strength, ductility and hardness, and are suitable for different application scenarios. It is necessary to select the appropriate aluminum coil state according to the actual application requirements to achieve the best use effect.

| 1050 Aluminum Coil State | Features |

|---|---|

| 1050 H12 Aluminum Coil | H12 has high ductility and strength, but lower than H14 state |

| 1050 H14 Aluminum Coil | H14 has high ductility and strength, and has a wide range of applications |

| 1050 H16 Aluminum Coil | H16 has higher strength and hardness, but lower than H18 state |

| 1050 H18 Aluminum Coil | H18 has the highest strength and hardness |

1050 H12 Aluminum Coil

The 1050 aluminum coil in the H12 state has higher ductility and strength, but lower than the H14 state.

Aluminum coils in this state are widely used in the fields of food packaging, electronics, chemicals, and construction, such as for making lamps, interior decoration materials, doors and windows, and auto parts.

1050 H14 Aluminum Coil

The 1050 aluminum coil in the H14 state has high ductility and strength, and has a wide range of applicability.

Aluminum coils in this state are usually used in food packaging, electronics, chemicals, construction, home appliances and other fields, such as beverage boxes, metal covers, lamps, aluminum alloy doors and windows, refrigerators, washing machines, etc.

1050 H16 Aluminum Coil

The 1050 aluminum coil in the H16 state has higher strength and hardness, but lower than the H18 state.

Aluminum coils in this state are mainly used in packaging, electronics, construction, home appliances, automobiles and other fields, such as for making auto parts, metal cans, lamps, refrigerators, induction cookers, etc.

1050 H18 Aluminum Coil

The 1050 aluminum coil in the H18 state has the highest strength and hardness.

Aluminum coils in this state are mainly used in food packaging, electronics, chemical industry, aerospace and other fields, such as high-pressure containers, aircraft structural parts, chemical equipment, wires, etc.

1050 Aluminum Coil Applications

1050 Aluminum Coil Strip for Architecture and Decoration

1050 aluminum coils are often used to make roofs, wall panels, ceilings, door and window frames, decorative panels, indoor and outdoor decoration, etc.

1050 aluminum coil has good corrosion resistance and decorative properties, and at the same time is light in weight and easy to process, making it an ideal choice for the architectural decoration industry.

- Status : O, H12, H14

- Thickness : 0.1-6.0mm

- Width : 1000-2000mm

1050 Aluminum Coil Strip for Package

1050 aluminum coils are widely used in the food packaging industry, such as making beverage lids, food cans, tableware, etc.

1050 aluminum coil has good corrosion resistance and decorative properties, and at the same time is light in weight and easy to process, making it an ideal choice for the architectural decoration industry.

- Status : O, H14

- Thickness : 0.1-0.5mm

- Width : 200-1200mm

1050 Aluminum Coil Strip for Electronic

1050 aluminum coils are often used to make capacitors, wires, batteries and other electronic devices, electrolytic capacitors, TV backplanes, battery shells, etc.

1050's excellent electrical properties and good processing performance are the main reasons for its application in the electronics industry. 1050 aluminum alloy is also sometimes used to make heat sinks because it has a higher thermal conductivity than other alloys.

- Status : O, H14

- Thickness : 0.1-3.0mm

- Width : 1000-1500mm

1050 Aluminum Coil Strip for Chemicals and Automotive

1050 aluminum coils are often used to make chemical storage tanks, auto parts, heat exchangers, etc.

Chemical industry : 1050 aluminum coils are widely used in the chemical industry to manufacture chemical containers, storage tanks and pipelines and other equipment. Due to its good corrosion resistance and cost-effectiveness, 1050 aluminum coils are increasingly used in the chemical industry.

Automobile : 1050 aluminum coil is mainly used in the manufacture of body panels, roof panels and interior panels in the field of automobile manufacturing. Its light weight, high strength and corrosion resistance can effectively improve the fuel economy and safety performance of the car.

- Status : O, H14

- Thickness : 0.1-5.0mm

- Width : 1000-2000mm

| Alloy Temper | Specified | Tensile strength | Yield strength | Elongation |

| Thickness(mm) | (MPa) | (MPa) | (%) | |

|

1050-O/ 1050-H111 |

0.2-0.5 | 65-95 | Min20 | Min20 |

| 0.5-1.5 | Min22 | |||

| 1.5-3.0 | Min26 | |||

| 3.0-6.0 | Min29 | |||

| 6.0-12.5 | Min35 | |||

| 1050-H112 | 6.0-12.5 | Min75 | Min30 | Min20 |

| 12.5-80.0 | Min70 | Min25 | ||

| 1050-H12 | 0.2-0.5 | 85-125 | Min65 | Min2 |

| 0.5-1.5 | Min4 | |||

| 1.5-3.0 | Min5 | |||

| 3.0-6.0 | Min7 | |||

| 6.0-12.5 | Min9 | |||

| 12.5-40.0 | ||||

| 1050-H14 | 0.2-1.5 | 105-145 | Min85 | Min2 |

| 1.5-3.0 | Min4 | |||

| 3.0-6.0 | Min5 | |||

| 6.0-12.5 | Min6 | |||

| 12.5-25 | ||||

| 1050-H16 | 0.2-0.5 | 120-160 | Min100 | Min1 |

| 0.5-1.5 | Min2 | |||

| 1.5-4.0 | Min3 | |||

| 1050-H18 | 0.2-0.5 | Min135 | Min120 | Min1 |

| 0.5-1.5 | Min140 | Min2 | ||

| 1.5-3.0 | Min2 | |||

| 1050-H19 | 0.2-0.5 | Min155 | Min140 | Min1 |

| 0.5-1.5 | Min150 | Min130 | ||

| 1.5-3.0 | ||||

| 1050-H22 | 0.2-0.5 | 85-125 | Min55 | Min4 |

| 0.5-1.5 | Min5 | |||

| 1.5-3.0 | Min6 | |||

| 3.0-6.0 | Min11 | |||

| 6.0-12.5 | Min12 | |||

| 1050-H24 | 0.2-0.5 | 105-145 | Min75 | Min3 |

| 0.5-1.5 | Min4 | |||

| 1.5-3.0 | Min5 | |||

| 3.0-6.0 | Min8 | |||

| 6.0-12.5 | ||||

| 1050-H26 | 0.2-0.5 | 120-160 | Min90 | Min2 |

| 0.5-1.5 | Min3 | |||

| 1.5-4.0 | Min4 | |||

| 1050-H28 | 0.2-0.5 | Min140 | Min110 | Min2 |

| 0.5-1.5 | ||||

| 1.5-3.0 | Min3 |