- What is Aluminum Trim Coil?

- What is Aluminum Trim Coil Used for?

- What Kind of Aluminum is Used for Trim Coil?

- What Gauge is Aluminum Trim Coil?

- How To Paint Aluminum Trim Coil?

- What Are The Different Types Of Aluminum Trim Coil?

- How Long Does Aluminum Trim Coil Last?

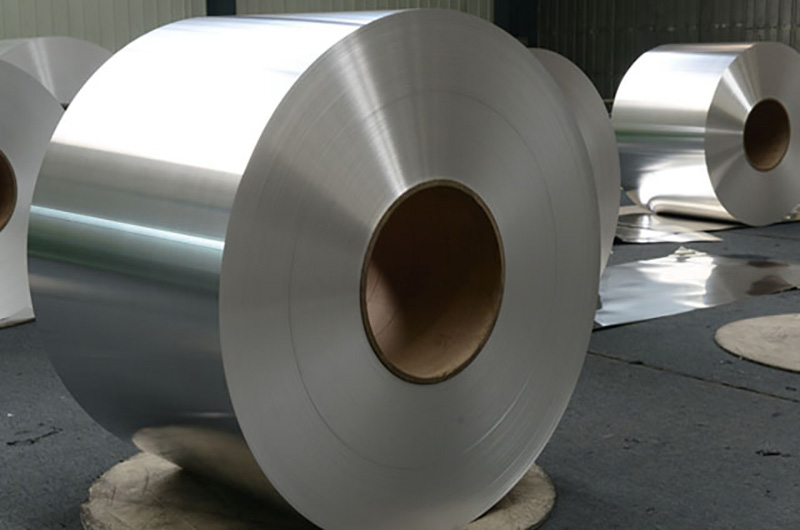

What is Aluminum Trim Coil?

Aluminum Trim Coil is a thin, flexible metal coil made of aluminum. Aluminum decorative coils are available in a variety of colors and finishes that can be easily matched with the overall design of a building. It is also durable and requires low maintenance, which makes it ideal for exterior applications.

Aluminum Trim Coil is usually sold in rolls that can be cut and bent to meet the specific needs of a building or project. It's lightweight, easy to handle, and can be installed quickly and efficiently, making it a popular choice for contractors and builders.

What is Aluminum Trim Coil Used for?

- Aluminum Trim Coil is commonly used as a decorative material on the exterior of buildings to cover wood trim of buildings such as rooflines, window and door edges, etc. It can make the building look more beautiful and durable, while also protecting the wood veneer from moisture and corrosion.

- Aluminum Trim Coil can also be used in the automobile manufacturing industry to make decorative trims and stripes on the vehicle to increase the appearance and quality of the car.

- In the field of consumer electronics manufacturing, Aluminum Trim Coil is also used to make the casings and exterior decorations of products such as televisions and computers, making them look more modern and stylish.

What Kind of Aluminum is Used for Trim Coil?

The alloys generally used in Aluminum Trim Coil are mainly 3xxx series and 5xxx series aluminum alloys. Among them, 3003 and 3105 alloys are commonly used. These alloys have good corrosion resistance, weldability and formability, and are suitable for manufacturing exterior wall decoration, door and window frames, body panels and other products. In addition, some manufacturers will choose other alloys, such as 5005 and 5052, according to specific use requirements.

| Alloy | Temper |

|---|---|

| 3003 | O, H12, H14, H16, H18, H22, H24, H26, H28 |

| 3105 | O, H12, H14, H16, H18, H22, H24, H26, H28 |

| 5005 | O, H12, H14, H16, H18, H32, H34, H36, H38 |

| 5052 | O, H12, H14, H16, H18, H32, H34, H36, H38 |

| Alloy | Advantages |

|---|---|

| 3003 | Good corrosion resistance and formability, good weldability, high strength |

| 3105 | Good corrosion resistance and formability, good weldability, high strength, good surface quality |

| 5005 | Good corrosion resistance and formability, good weldability, high strength, good surface quality, good processability |

| 5052 | Good corrosion resistance and formability, good weldability, high strength, good surface quality, good processability, good wear resistance, good bendability |

| Alloy | Applications |

|---|---|

| 3003 | Building exterior decoration, door and window frames |

| 3105 | Building exterior decoration, automotive body panels, door and window frames |

| 5005 | Door and window frames, automotive body panels |

| 5052 | Automotive body panels, shipbuilding, oil tanks, pipelines |

It should be noted that the above are only common applications and alloy states, and the specific application and selected alloy state will also be affected by other factors, such as manufacturing process, environmental requirements, etc.

What Gauge is Aluminum Trim Coil?

Aluminum trim coils are available in a variety of gauges or thicknesses depending on intended use and application.

- Common gauges for aluminum trim coils range from 0.019" to 0.024".

- Thicker Aluminum Trim Coil for heavy duty applications

- Thinner Aluminum Trim Coil is good for light projects.

The exact specification of the aluminum trim roll required will depend on project requirements such as the size of the trim desired, weather exposure, and strength required. It is best to consult the manufacturer or supplier to determine the appropriate specifications for your particular application.

How To Paint Aluminum Trim Coil?

Painted aluminum trim rolls are a great way to customize and protect the exterior of your building. The following is the processing flow of painted aluminum decorative coil :

- Cleaning The Surface : Before painting, it is very important to clean the surface of your trim coil to remove any dirt, dust or debris. Clean the surface with a mild detergent and water, then rinse thoroughly and allow to dry completely.

- Sand the surface : To help the paint adhere better to the surface of the aluminum trim coil, lightly sand the surface with fine-grit sandpaper. This will help remove any rough spots or oxidation.

- Primer : Apply a high-quality primer to the surface of the aluminum trim coil. A primer will help the paint adhere better and provide extra protection.

- Painting : After the primer has dried, apply a high-quality exterior paint to the surface of the aluminum trim coil. Apply the paint using a brush, roller, or sprayer, following the manufacturer's directions for the particular type of paint being used.

- Drying and Curing : Allow paint to dry completely according to manufacturer's instructions. It is very important to allow the paint to fully cure before exposing the trim coil to any harsh weather conditions.

- Touch-up as needed : After the paint has cured, inspect the surface of the trim coil and touch-up any areas that may be needed.

What Are The Different Types Of Aluminum Trim Coil?

- Smooth Finish : Finish trim coils have a flat, smooth surface ideal for applications requiring a clean, smooth look. It is commonly used for window and door trim, fascias and other exterior elements.

- Textured Finish : Textured finish trim coil has a textured surface that adds depth and dimension to exterior elements. It is often used for decorative accents and to add visual interest to the exterior of buildings.

- Wood Grain Finish : Wood Grain Finish decorative coil has a textured surface that resembles the look of wood. It is often used to create a natural, rustic look to exterior elements such as fascias, soffits, door and window trim.

- Embossed Finish : Embossed finish decorative coils feature a patterned surface that adds texture and visual interest to exterior elements. It is commonly used for decorative accents and to create a unique bespoke look to the exterior of a building.

- Color-coated finishes : Color-coated trim coils are pre-painted and available in a variety of colors that easily match the color scheme of a building's exterior. It is commonly used for window and door trim, fascias and other exterior elements.

It is important to select the correct type of Aluminum Trim Coil for a specific application and requirements. If you are unsure which type of Aluminum Trim Coil to use, it is recommended that you consult a professional contractor or supplier.

How Long Does Aluminum Trim Coil Last?

The service life of Aluminum Trim Coil depends on various factors such as its thickness, quality, installation and exposure to environmental factors. Generally speaking, high-quality aluminum coils can be used for 20-30 years or more, while low-quality ones may only be used for 5-10 years.

Factors that can affect the life of aluminum trim coils include exposure to UV light, moisture, extreme temperatures and physical damage such as impact or bending. Proper installation, including adequate sealing and proper seating, will also help extend the life of trimmer coils.

It's important to note that regular maintenance, such as cleaning and repainting as needed, will also help extend the life of your aluminum trim coils. Ultimately, the lifespan of your aluminum trim coil depends on a variety of factors, and it is important to choose a high-quality product and ensure it is installed and maintained properly for best results.

Aluminum Trim Coil is usually sold in rolls that can be cut and bent as needed to suit a variety of different building and design needs. It is also popular with construction and manufacturing for its durability and low maintenance costs.

Haomei Aluminum is a professional aluminum coil manufacturer with many years of rich production experience. We use high-quality aluminum alloy materials, adopt advanced production technology and strict quality control to ensure that our products have good corrosion resistance, formability, surface quality, weldability and strength, as well as rich color and coating options . No matter what shape, size or color you need Aluminum Trim Coil, we've got you covered.

We not only provide high-quality products, but also provide high-quality pre-sale consultation, after-sales service and technical support. If you have any questions or needs related to Aluminum Trim Coil, please feel free to contact us, we will serve you wholeheartedly!