- Why use mortar embossed aluminum coils for pipe insulation?

- Factors to consider when choosing stucco embossed aluminum coils

- Specifications of Stucco Embossed Aluminum Coils for Pipe Insulation

- What is the installation method of stucco embossed aluminum coil?

- How to deal with the seams of stucco embossed aluminum coils?

- Are stucco embossed aluminum coils waterproof?

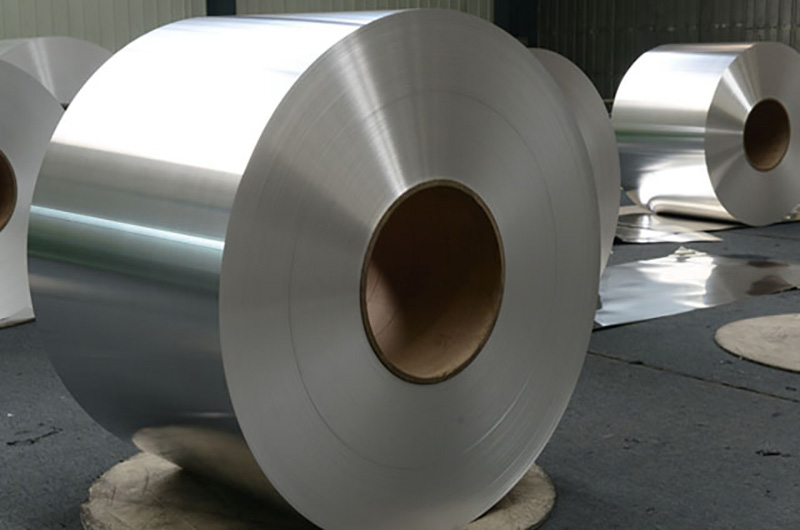

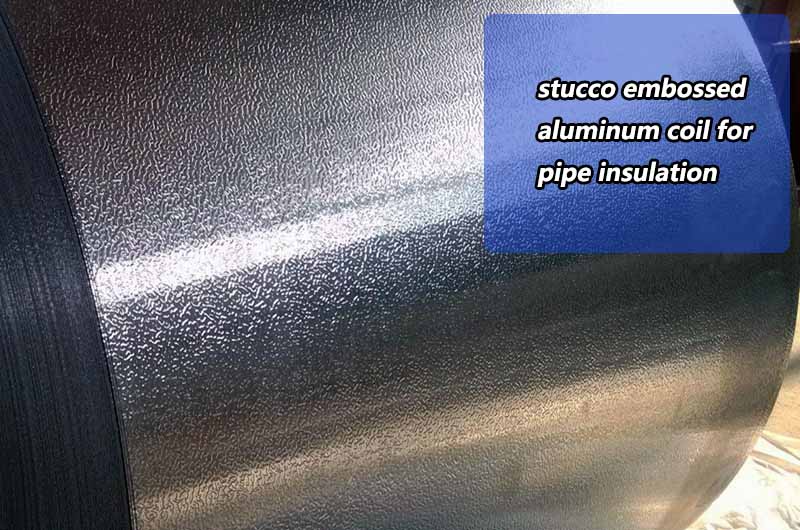

Stucco embossed aluminum coils are often used for the outer cladding of pipe insulation systems. This material has certain thermal insulation and protective properties and can effectively insulate and protect piping systems.

Why use mortar embossed aluminum coils for pipe insulation?

The main purpose of using mortar embossed aluminum coils in pipe insulation is to improve the insulation effect and protective performance. Here are some possible reasons:

- 1. Thermal conductivity: Aluminum has good thermal conductivity and can effectively prevent the transfer of heat. By adding stucco embossed aluminum coils to the pipe insulation layer, the thermal conductivity can be increased, thereby improving the insulation effect of the pipe.

- 2. Mechanical protection: Stucco has a certain hardness and pressure resistance, which can provide mechanical protection for the pipeline and prevent damage to the pipeline by external objects. The embossed surface of the aluminum coil can increase its strength and make it more resistant to external pressure and impact.

- 3. Corrosion resistance: Aluminum has good corrosion resistance and can resist corrosion from most chemicals. Therefore, using mortar embossed aluminum coils as the outer packaging of pipe insulation can increase the corrosion resistance of the pipe and extend its service life.

- 4. Beautiful appearance: Stucco embossed aluminum coils can not only improve the performance of the pipe, but also make the appearance more beautiful. This is especially important for some pipes that require exterior decoration or are used in public places.

In general, the use of stucco embossed aluminum coils can not only improve thermal conductivity, but also provide mechanical protection, corrosion resistance and aesthetics, thereby comprehensively improving the insulation effect and service life of the pipeline.

Factors to consider when choosing stucco embossed aluminum coils

- Thermal insulation performance: Ensure that the aluminum coil has sufficient thermal insulation properties to meet the thermal protection needs of the piping system.

- Weather resistance: Consider environmental factors and choose aluminum coils with good weather resistance and corrosion resistance.

- Thickness and Size: Select the appropriate aluminum coil thickness and size based on the diameter of the pipe and the required insulation thickness.

- Ease of Installation: Choose an easy-to-install design to reduce project cost and time.

Stucco embossed aluminum coils are widely used in pipe insulation systems, which can effectively reduce heat loss. At the same time, as a covering material for the evaporator of refrigeration equipment, it may help improve heat dissipation efficiency and play an important role in the refrigeration cycle.

Specifications of Stucco Embossed Aluminum Coils for Pipe Insulation

- Thickness range: The thickness range of stucco embossed aluminum coils is usually between 0.17mm and 1.5mm, which can be selected according to specific insulation requirements and application scenarios.

- Width specifications: Commonly used widths are 1m, 1.2m and 1.5m. These specifications can meet the needs of pipes of different diameters and refrigeration equipment of different sizes.

- Material: Common materials include 1060 and 3003 aluminum plates. These aluminum alloys generally have good processability, corrosion resistance and thermal conductivity, making them ideal for use in the manufacture of insulation and refrigeration equipment.

- Surface treatment: Embossed design can improve the surface strength and wear resistance of aluminum coils, while also increasing the aesthetics. This is important for products used in external environments.

In addition to being used for pipe insulation, stucco embossed aluminum coils are also commonly used in evaporators of refrigeration equipment such as refrigerators, freezers and air conditioners.

What is the installation method of stucco embossed aluminum coil?

Answer: Installing stucco embossed aluminum coils usually involves wrapping it around the outside of the pipe and securing it with a specialized adhesive or other fixing device. Make sure the surface is clean and the embossed aluminum coils fit evenly for best results.

How to deal with the seams of stucco embossed aluminum coils?

Answer: Seams often require special treatments to ensure sealing and aesthetics. This can be done using special connectors, glue or other sealing materials.

Are stucco embossed aluminum coils waterproof?

Answer: Stucco embossed aluminum coil itself is not waterproof, but it can be increased by suitable sealing treatment to ensure that the pipe system is not affected by humid environments.

Informations you may be interested in:

- 0.5mm thick 3003 anti-corrosion thermal insulation aluminum coil

- Aluminum Coil for Power Plant Insulation

- What precautions should be taken when applying thermal insulation aluminum coils?

- Characteristics and storage precautions of aluminum coils for thermal insulation

- What are the benefits of aluminum insulation?

- Is aluminum a good thermal insulator?

- 1050 thermal insulation aluminum coil