- The principle of aluminum materials for ships

- When choosing an aluminum alloy for ships, why should you consider the height ratio and the amount of mode?

- Why do ships use aluminum alloy aluminum alloy with medium intensity and corrosion resistance?

- Why is the welding performance an important consideration when choosing a ship for a ship?

- Why consider the corrosion resistance of aluminum alloy for ships?

- Why is the cold and thermal forming performance considering the factors when choosing a ship for aluminum alloy?

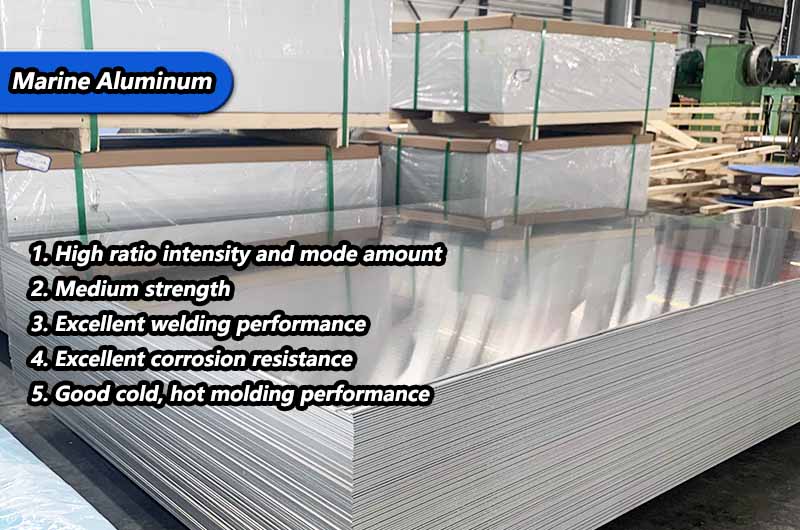

Because ship aluminum alloy is used in marine ships and other fields, it has stricter process requirements and performance standards than other ordinary aluminum alloy products.

At present, ship aluminum alloys are mostly used in aluminum alloy products such as 5083, 5086, 5454, 5754, and 6061. In practical applications, the advantages of boat aluminum alloy are very obvious.

The principle of aluminum materials for ships

- High ratio intensity and mode amount

- Medium strength

- Excellent welding performance

- Excellent corrosion resistance

- Good cold, hot molding performance

When choosing an aluminum alloy for ships, why should you consider the height ratio and the amount of mode?

Answer: The yield strength and elastic modulus of the material are the basic parameters of the strength calculation of the ship structure and determining the structure size. Increasing the yield strength within a certain range is conducive to reducing the weight of the ship's structure, and the density and elastic modulus of aluminum alloy are similar in general. Therefore, selecting a high -ratio aluminum alloy can reduce the weight of the hull while maintaining the structural strength.

Why do ships use aluminum alloy aluminum alloy with medium intensity and corrosion resistance?

Answer: High -intensity aluminum alloy is usually difficult to have good corrosion resistance and weldability at the same time. Therefore, in order to achieve a balance in the ship structure, the aluminum alloy for ships generally choose aluminum alloy with medium strength, corrosion resistance and weldability. This helps to ensure the durability and maintenance of the structure.

Why is the welding performance an important consideration when choosing a ship for a ship?

Answer: In shipbuilding, welding connections have obvious advantages compared to riveting connections, so welding methods have been widely used. Excellent welding performance means that the cracks formed by aluminum alloy during welding are smaller, that is, aluminum alloy has better welding cracking resistance. Because it is impossible to restore the performance of welding by re -heat treatment under shipbuilding conditions, good welding performance is one of the important features of ship aluminum alloy.

Why consider the corrosion resistance of aluminum alloy for ships?

Answer: The ship structure often runs in the harsh seawater media and marine environment. Therefore, whether aluminum alloy is corrosion -resistant is an important sign that determines whether it is applicable to ships. Ship aluminum alloys require stress corrosion, peeling corrosion and inter -crystal corrosion in seawater and marine environments. Try to avoid contact with corrosion, gap corrosion, and sealum adhesion, allowing small uniform corrosion and point corrosion.

Why is the cold and thermal forming performance considering the factors when choosing a ship for aluminum alloy?

Answer: During the construction process of ships, the ship needs to withstand cold processing and thermal processing. Therefore, the ship's aluminum alloy needs to have good cold and thermal molding performance. This means that there will be no defects such as cracks during processing, and it can still meet the performance requirements such as strength and corrosion resistance after processing. This is a key factor that ensures that the hull structure can meet the design requirements during the construction process.

Informations you may be interested in:

- 5083 5086 Aluminum plate for ship deck

- Best aluminum for salt or fresh water

- Best aluminum for marine use

- Aluminum Plate for Yachts Building

- LPG natural gas (LNG) transport ship for 5083 aluminum plate

- 9 Advantages Aluminum AlLoy in Ship Applications

- 6 proplems welding of ship aluminum

- How to treat corrosion treatment for boat aluminum plates?

- Temper of marine aluminum alloys

- 5059 O H111 H116 H321 Marine Aluminum Plate Sheet