- Composition of Marine-Grade Aluminum Checker Plate

- Specification of Marine Grade Aluminum Tread Plate

- Performance of Marine Grade Aluminum Checkered Plate

- Marine Grade Aluminum Tread Plate Applications

- Marine grade aluminum checker plate precautions

- Marine grade aluminum checker plate manufacturing process

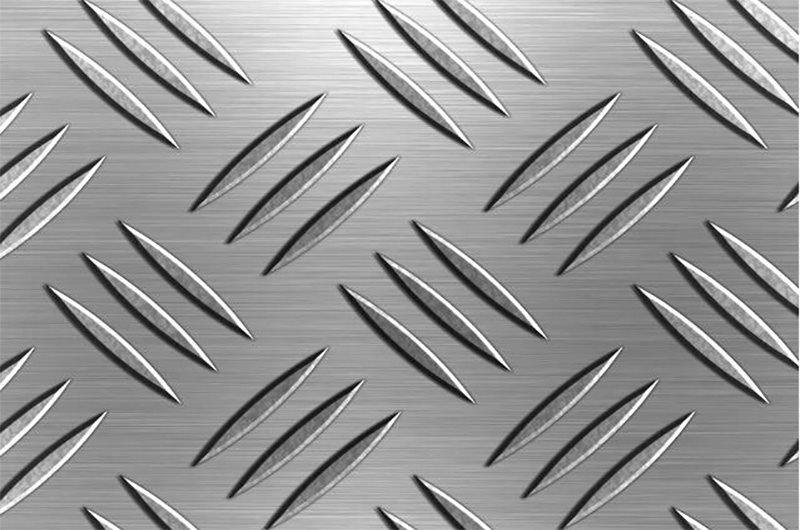

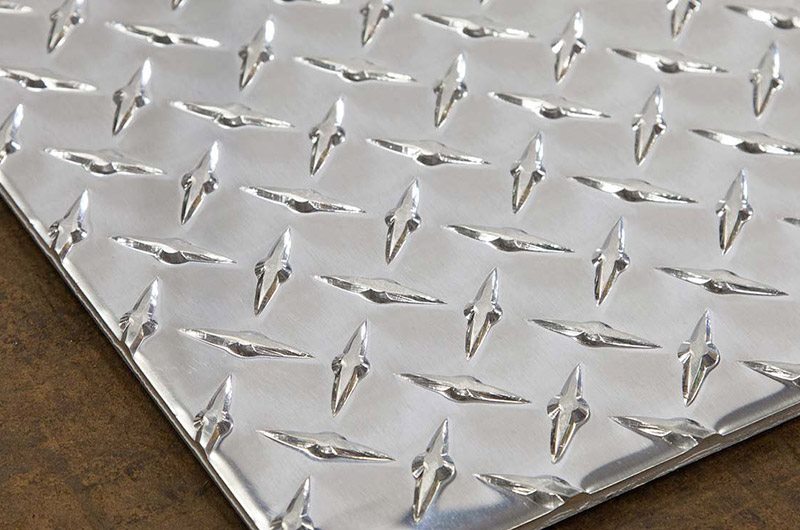

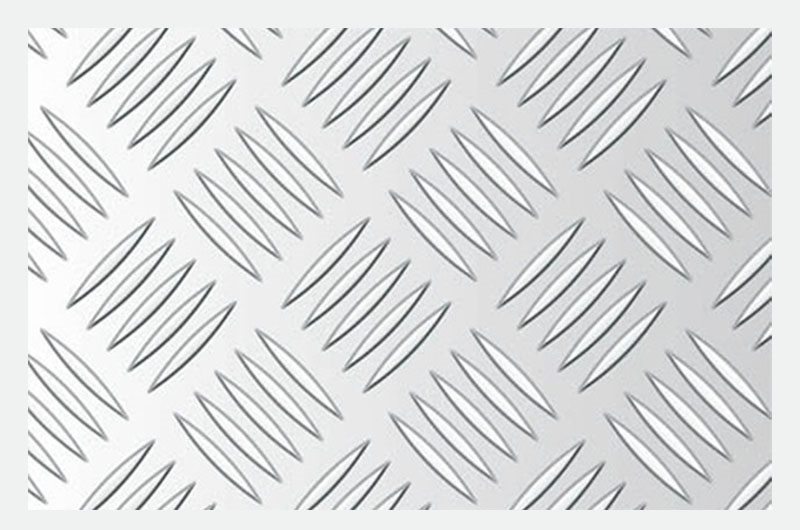

Marine-grade aluminum checker plate, also known as aluminum tread plate or aluminum diamond plate, is a type of aluminum sheet with a raised pattern of lines or diamonds on one side.

This pattern provides extra grip and slip resistance, making it suitable for applications in marine environments where traction is important.

Composition of Marine-Grade Aluminum Checker Plate

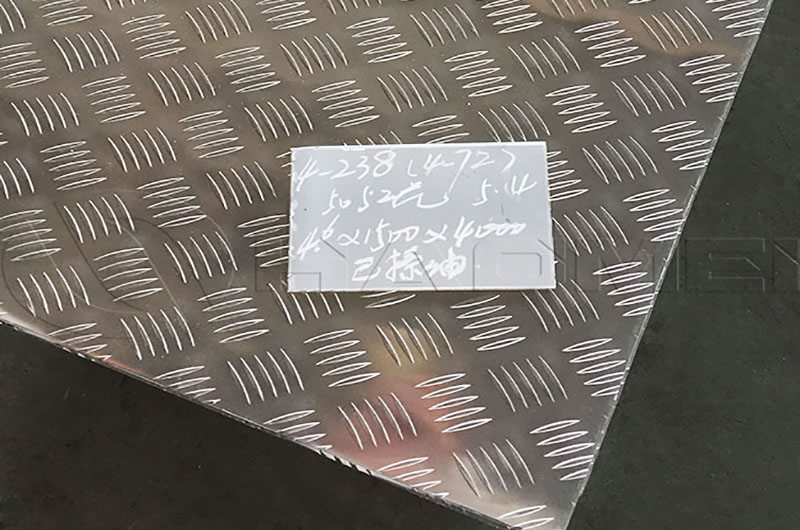

Marine grade aluminum checkered plates are commonly used on ship decks due to their excellent anti-slip properties and excellent corrosion resistance. The main varieties are 5052, 5086 and 5083.

| Alloy | 5052 | 5083 | 5086 |

|---|---|---|---|

| Si | 0.25 | 0.4 | 0.4 |

| Fe | 0.4 | 0.4 | 0.5 |

| Cu | 0.1 | 0.1 | 0.1 |

| Mn | 0.1 | 0.40-1.0 | 0.20-0.7 |

| Mg | 2.2-2.8 | 4.0-1.0 | 3.5-4.5 |

| Cr | 0.15-0.35 | 0.05-0.25 | 0.05-0.25 |

| Ni | - | - | - |

| Zn | 0.1 | 0.25 | 0.25 |

| Ti | - | 0.15 | 0.15 |

| Ga | - | - | - |

| V | - | - | - |

| Each | 0.05 | 0.05 | 0.05 |

| Total | 0.15 | 0.15 | 0.15 |

| Alu | Remainder | Remainder | Remainder |

Specification of Marine Grade Aluminum Tread Plate

Aluminum alloy grade: AA5083, 5086, 5052 (H116, H321) Pattern: 3 bars, 5 bars, diamond. Thickness: 0.8 – 12mm Width: 400-1220mm Length: max 6000mm Length & width tolerance: ± 10%. Thickness tolerance: ± 0.1 mm.

| Surface | Bright finish, Mill finish | |

|---|---|---|

| Mill Finish Surface | Bright Finish Surface | |

| Thickness | 1.00-6.50mm | 1.20-6.50mm |

| Pattern height | Sheet Thickness from 1.0mm to 2.0mm, bar height: 0.5mm | Sheet Thickness from 1.0mm to 2.0mm, bar height: 0.5mm |

| Sheet Thickness from 1.0mm to 2.0mm, bar height: 1.0mm | Sheet Thickness from 1.0mm to 2.0mm, bar height: 1.0mm | |

| Sheet Thickness above 2.0mm, bar height: 1.5mm | Sheet Thickness above 2.0mm, bar height: 1.5mm | |

| Normal size | 1200×2400mm, 1219×2438mm, 1219×3048mm | 1200×2400mm, 1219×2438mm, 1219×3048mm |

Performance of Marine Grade Aluminum Checkered Plate

Marine grade aluminum checkered panels offer a range of properties that make them ideal for use in marine environments. These properties contribute to its corrosion resistance, strength and overall performance.

1. Corrosion resistance

The alloy components, especially the presence of magnesium, impart excellent corrosion resistance. This is critical to withstand the corrosive effects of salt water in marine applications.

2. Strength and durability

The raised lattice pattern not only provides slip resistance but also enhances the overall strength and durability of the aluminum panels. This is critical to withstand the harsh conditions encountered in the marine environment.

3. light

Aluminum's inherent light weight makes marine-grade tread plate the first choice for applications where weight is a critical factor. Its low density helps reduce the overall weight of marine structures.

4. Formability

Marine-grade aluminum is highly formable, benefiting a variety of manufacturing processes. This includes cutting, bending and welding, providing design and installation flexibility.

Marine Grade Aluminum Tread Plate Applications

Marine Grade Aluminum Tread Plate has long been used in large, medium and small passenger ships, cruise ships, motor boats, high-speed missile boats, patrol boats, destroyers, fishing boats, etc. It has good anti-skid effect, strong anti-rust ability and light weight.

- Boat Decks

- Docks and Piers

- Gangways and Ramps

- Marine Platforms

- Boat Cabin Floor

- Marine Vehicles

Marine grade aluminum checkered panels are used in a wide range of marine applications where slip resistance, corrosion resistance and durability are critical. The versatility of this material makes it a first choice for building a variety of marine structures.

ship deck

One of the main applications of marine aluminum grating is in the construction of ship decks. The anti-slip properties of the plaid pattern increase safety, especially in wet conditions.

piers and piers

Piers and piers are exposed to the corrosive effects of salt water. The structures are constructed using marine-grade aluminum lattice panels to ensure longevity and corrosion resistance.

gangways and ramps

Gangways and ramps on ships and offshore platforms benefit from the anti-slip surface of lattice panels, providing safe passage for people and equipment.

Offshore platforms

Various marine platforms, including oil rigs and offshore structures, use marine-grade aluminum grating for floors and walkways. In these challenging environments, its corrosion resistance is critical.

Boat Cabin Floor

In addition to exterior marine structures, marine-grade lattice panels can also be used in interior applications such as cabin floors and storage rooms.

marine vehicles

Aluminum lattice panels are also used in the construction of vessels such as ships and ferries, where their lightweight properties help improve fuel efficiency and overall performance.

Understanding the many applications of marine grade aluminum checkered panels highlights its importance in improving safety and durability in a variety of marine environments.

Marine grade aluminum checker plate precautions

1. Coating and protection

Applying a protective coating, such as varnish or a specialized marine coating, can provide an additional layer of protection against corrosion. These coatings act as a barrier, preventing direct contact between the aluminum surface and corrosive elements.

2. Store correctly

If marine grade aluminum checkered panels are stored for long periods of time, they should be kept in a dry environment to prevent moisture from accumulating and accelerating corrosion.

By adhering to correct maintenance practices, users can ensure the longevity and continued performance of marine grade aluminum grating in marine applications.

Marine aluminum pattern plate is an important material in the fields of marine engineering and construction. Its unique combination of corrosion resistance, strength and slip resistance makes it an indispensable product for a variety of applications, from ship decks to offshore platforms.

Marine grade aluminum checker plate manufacturing process

The production of marine grade aluminum pattern plate involves several key processes, each contributing to the quality and performance of the final product.

1. Aluminum castings

The process begins with casting an aluminum ingot or billet. At this stage, the alloy composition is carefully controlled to achieve the desired properties.

2. Hot rolling

The cast aluminum is then hot rolled into thin sheets. The hot rolling process refines the grain structure and improves the strength and formability of the material.

3. Surface treatment

The surface of the aluminum plate is treated to form a unique grid pattern. This is accomplished through a process called embossing or rolling, which involves passing the paper through specialized rollers that impart a raised pattern.

4. Cutting and finishing

After the pattern is formed, the sheet is cut to the desired size. Finishing processes such as trimming and deburring ensure that the final product meets quality standards.

Informations you may be interested in: