- What Is The Advantage of Aluminum Ceiling?

- How Thick is Aluminum Strip Ceiling?

- What are the Color and Finish Options for Aluminum Strip Ceilings?

- What Kind of Aluminum is Used for Ceiling?

- What is Aluminum Strip Used for?

- How is the Aluminum Bar Ceiling Installed?

- How to Maintain the Aluminum Bar Ceiling?

- Are Aluminum Bar Ceilings Fire Resistant?

- Does the Aluminum Strip Ceiling Comply with Environmental Protection Requirements?

Aluminum strip ceiling is a kind of ceiling system with thin aluminum strip as the main component. These strips are usually installed in a parallel pattern to create a uniform and sleek look. Aluminum strip ceiling systems offer a range of advantages including ease of installation, low maintenance, fire resistance and durability. They are commonly used in commercial and residential buildings, as well as public spaces such as airports and transportation hubs.

What Is The Advantage of Aluminum Ceiling?

Advantages of aluminum ceilings include light weight, easy installation, durability, low maintenance, and resistance to moisture, fire, and corrosion. Additionally, aluminum ceilings can be painted in various finishes and colors to provide a modern and aesthetic look.

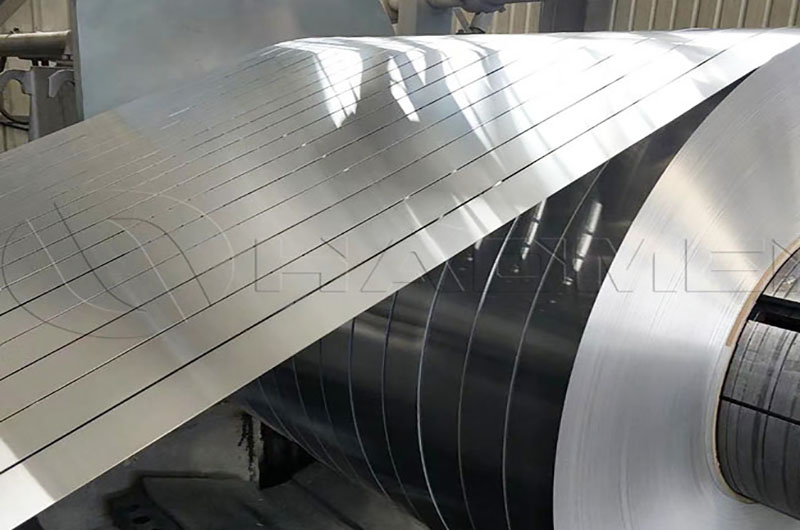

How Thick is Aluminum Strip Ceiling?

The thickness of the aluminum strip ceiling can vary according to the specific product and manufacturer. However, the thickness is usually in the range of 0.5 mm to 1.0 mm.

As for the commonly used sizes of aluminum strip ceilings, they can be varied. Some popular specifications on the market include :

- Width : 100mm, 150mm, 200mm, 300mm, 400mm, 500mm, 600mm, 800mm, 900mm, 1000mm, 1200mm, etc.

- Length : Usually within 6 meters, but can be customized.

- Thickness : 0.5mm, 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.1mm, 1.2mm, etc.

The exact thickness and size of the aluminum strip ceiling chosen will depend on factors such as the desired aesthetic, structural requirements and installation method.

What are the Color and Finish Options for Aluminum Strip Ceilings?

The color and finish of the aluminum bar ceiling can be customized according to the needs of customers :

- Color : Gold, silver, white, black and other basic colors, and other personalized colors and patterns.

- Surface treatment : various methods such as texture, spraying, and electrophoretic painting can be selected.

What Kind of Aluminum is Used for Ceiling?

The type of aluminum used for ceilings can also vary by product and application. However, the 3000 and 5000 series aluminum alloys are commonly used for their high strength, corrosion resistance and machinability. Additionally, some aluminum strip ceiling products may contain recycled aluminum, making it a more sustainable option.

The most commonly used aluminum alloy for smallpox is 3003 aluminum alloy. This alloy has excellent formability, high corrosion resistance and good weldability, making it ideal for ceiling applications. Other aluminum alloys used in ceiling applications include 1100, 1060 and 5052 alloys, depending on the specific requirements of the project.

In addition to the alloy, the hardness of aluminum is also important for ceiling applications. The commonly used tempering degrees of aluminum strip ceilings are H14, H24, H26, etc., which have good strength and stability. The choice of aluminum alloy and temper will depend on the specific needs of the project, including desired aesthetics, structural requirements and environmental considerations.

What is Aluminum Strip Used for?

Aluminum strips are used in a variety of applications including building materials such as suspended ceilings, trim and exterior cladding. In addition, aluminum strips have the advantages of light weight, high strength, and corrosion resistance, and can be used in electrical conductors, packaging materials, and automotive parts, among others.

- Building materials : Aluminum strips are used in building materials such as window frames, door frames, roofing and wall panels. These products are lightweight, durable and corrosion resistant, making them ideal for architectural applications.

- Suspended Ceilings : Aluminum strips are used for the suspended ceilings of commercial buildings such as offices, hospitals, schools, etc. These strips are connected to a metal grid system to create a smooth and seamless ceiling surface. They are available in a variety of sizes, thicknesses and finishes to match the desired design aesthetic.

- Decorative elements : Aluminum strips are also used as decorative elements in interior design. They can be used to create accent walls, backsplashes, and other design features. Aluminum bars are available in a variety of colors and finishes including brushed, polished and anodized to match the desired design aesthetic.

- Exterior Cladding : Aluminum strips are used in the exterior cladding of buildings to provide a durable and low maintenance finish. They can be used in various forms such as sheets, panels and composites. Aluminum strips used for exterior cladding are specially coated or finished to increase their weather resistance, durability and fire resistance.

How is the Aluminum Bar Ceiling Installed?

There are three main installation methods for aluminum strip ceilings : suspension type, plug-in type and gusset type. Suspension installation needs to install the suspension system on the ceiling first, and then hang the aluminum strip panel on the suspension system; the plug-in type and gusset type are to insert or buckle the aluminum strip panel into the keel installed on the wall or ceiling.

How to Maintain the Aluminum Bar Ceiling?

Aluminum strip ceilings generally do not require special maintenance. Daily cleaning can be wiped with water or a neutral detergent, and avoid using strong acid-base cleaners and brushes to scratch the surface. If the aluminum strip panel is scratched or deformed, it needs to be replaced or repaired in time.

Are Aluminum Bar Ceilings Fire Resistant?

Most aluminum strip ceilings have good fire performance and meet relevant fire protection standards and requirements. For example, the aluminum bar ceiling made of Class A fireproof materials can effectively prevent the spread of fire and ensure the safety of personnel.

Does the Aluminum Strip Ceiling Comply with Environmental Protection Requirements?

Most of the aluminum strip ceilings meet the requirements of environmental protection, which is mainly reflected in the renewable and non-polluting nature of the material itself. Aluminum is a recyclable resource that can be recycled and utilized repeatedly. At the same time, the production process is non-toxic and harmless, and will not pollute the environment.

Informations you may be interested in: