- What is embossed kraft paper aluminum foil?

- Uses of embossed kraft paper composite aluminum foil

- Embossed Kraft Paper Laminated Aluminum Foil Alloy

- Embossed Kraft Paper Laminated Aluminum Foil Benefits

- Embossed Kraft Paper Laminated Aluminum Foil Manufacturing Process

- Precautions when using embossed kraft paper composite aluminum foil

In the field of packaging materials, embossed kraft paper laminated aluminum foil is a versatile and efficient option. This composite material combines the durability and barrier properties of aluminum foil with the strength and natural beauty of kraft paper.

What is embossed kraft paper aluminum foil?

Embossed kraft paper composite aluminum foil is a composite material made of a layer of aluminum foil with an embossed pattern and a layer of kraft paper bonded together.

- Aluminum foil blocks moisture, light, oxygen and other environmental factors.

- Kraft paper provides strength, tear resistance and a natural look.

- The embossed pattern on the aluminum foil not only enhances its aesthetics but also increases its strength and flexibility.

Uses of embossed kraft paper composite aluminum foil

The versatility of embossed kraft paper composite aluminum foil makes it suitable for a wide range of applications in various industries:

- 1. Packaging: One of the main uses of this material is packaging. It is commonly used to package food items such as chocolate, cheese, butter and snacks, providing excellent protection against moisture and contamination while maintaining the freshness of the contents. Additionally, it is used for packaging pharmaceuticals, chemicals, and industrial products.

- 2. Insulation: The combination of aluminum foil and kraft paper makes this material an excellent choice for insulation purposes. It is used in construction to provide insulation for walls, roofs, and HVAC systems. The reflective properties of aluminum foil help minimize heat transfer, while the kraft paper adds durability and strength.

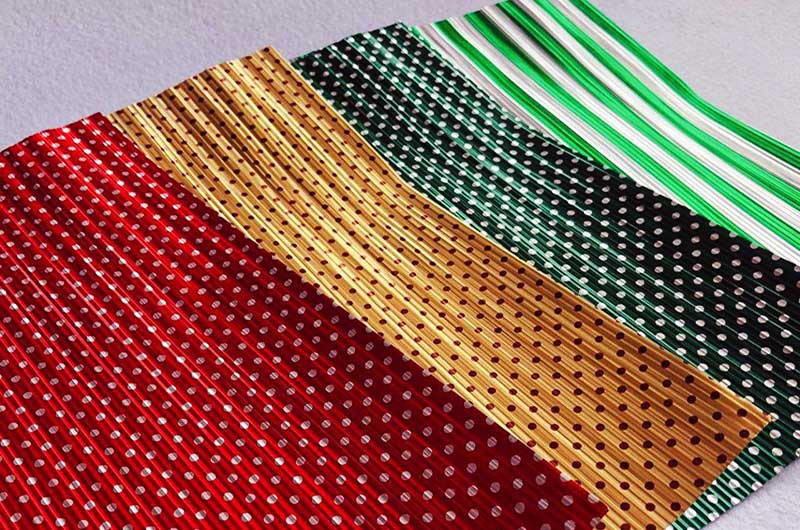

- 3. Decorative applications: The embossed patterns on aluminum foil are ideal for decorative applications. This material is commonly used in arts and crafts projects, as well as for decorative purposes in interior design and gift wrapping.

- 4. Electrical insulation: In the electrical industry, embossed laminated kraft paper aluminum foil is used for the insulation of transformers, cables and other electrical components. The combination of aluminum foil and kraft paper provides excellent dielectric strength and thermal stability.

Embossed Kraft Paper Laminated Aluminum Foil Alloy

The choice of aluminum foil alloy is critical to ensuring the desired properties of the final product. Commonly used alloys include:

8011 embossed laminated alu foil with kraft paper

8011 is a commonly used aluminum foil alloy with excellent properties, including high tensile strength, good formability and corrosion resistance. Alloy 8011 is ideal for applications requiring high barrier properties and heat resistance.

1235 embossed laminated alu foil with kraft paper

1235 is another popular aluminum foil choice. Alloy 1235 has good thermal and electrical conductivity. It is commonly used in applications that require high purity and electrical insulation, such as electrical insulation materials.

Embossed Kraft Paper Laminated Aluminum Foil Benefits

- 1. Food grade, healthy, non-toxic, waterproof and oil-proof.

- 2. Good tensile strength and good heat sealing performance.

- 3. Suitable for manual work and automatic packaging machines.

- 4. Can be metalized or laminated with aluminum foil.

- 5. Any pattern or color can be printed on it.

Embossed Kraft Paper Laminated Aluminum Foil Manufacturing Process

The manufacturing process of kraft paper embossed composite aluminum foil includes the following steps:

- 1. Preparation of aluminum foil: The process starts with the preparation of aluminum foil. High-quality aluminum ingots are melted and cast into thin sheets through a rolling process. The foil is then annealed to obtain the desired thickness and mechanical properties.

- 2. Aluminum foil embossing: The aluminum foil passes through an embossing roller to emboss the pattern or texture onto the surface of the aluminum foil. These patterns not only enhance the visual appeal of the foil but also increase its strength and flexibility.

- 3. Kraft paper laminated with aluminum foil: The embossed aluminum foil is then laminated to a layer of kraft paper. The two materials are bonded together by adhesive or heat pressure to form a strong and durable composite.

- 4. Finishing: After lamination, the composite may undergo additional finishing processes, such as coating or printing, depending on its intended application.

Precautions when using embossed kraft paper composite aluminum foil

While kraft embossed laminated aluminum foil offers many advantages, certain precautions must be observed when using it:

- 1. Avoid contact with acidic or alkaline substances: Aluminum foil will react with acidic or alkaline substances, causing material corrosion or degradation. It is recommended to avoid direct contact with such substances to prevent damage to the foil.

- 2. Handle with care: Although aluminum foil is durable, it can tear or puncture if not handled properly. Handle materials with care, especially when wrapping sharp or pointed objects, to avoid damage.

- 3. Keep away from open flames: Aluminum foil is flammable and should be kept away from open flames or high heat sources to prevent fire risks. Use caution when using this material near stoves, ovens, or other heat sources.

- 4. Proper disposal: Aluminum foil is recyclable, but should be disposed of properly to prevent environmental pollution. Clean and discard used foil in recycling bins designated for aluminum materials.

By following these precautions, users can maximize the benefits of kraft embossed laminated aluminum foil while minimizing potential risks.

Embossed kraft paper composite aluminum foil is a versatile and efficient material that has a wide range of applications in various industries. Its foil and kraft combination offers excellent barrier properties, strength and versatility, making it ideal for packaging, insulation and decorative purposes.