The alloy aluminum plate has the advantages of small proportions, high strength, good seawater corrosiveness, magnetic non -magnetic, and low temperature performance. As a structural material, it is increasingly valued in the shipbuilding industry.

The use of aluminum aluminum plates as a hull material can effectively reduce the weight of the ship, improve stability and speed, and enhance the technical and tactical performance of the ship. For high -speed taxi boats, wing boats, air cushion boats, small surface boats and some special use boats, it is especially suitable for using aluminum aluminum plates.

The chemical properties of aluminum and aluminum aluminum plates are very lively, but because it can produce dense oxide film with oxygen, it is much better than steel. When the alloy aluminum plate is used on the ship, no matter what part of it is, it will be more or less contact with the seawater, or the seawater droplets and the atmosphere of the ocean, which will be corroded to a certain amount.

Types of aluminum plate corrosion for ships

The corrosion of alloy aluminum plates is a very complicated process, which is both affected by the environment and the nature of the alloy. The types of corrosion commonly used in the marine environment in the marine environment of ships include: erosion, gap corrosion, inter -crystal corrosion, peeling corrosion, and stress corrosion and cracking.

Corrosion treatment of aluminum plates for ships

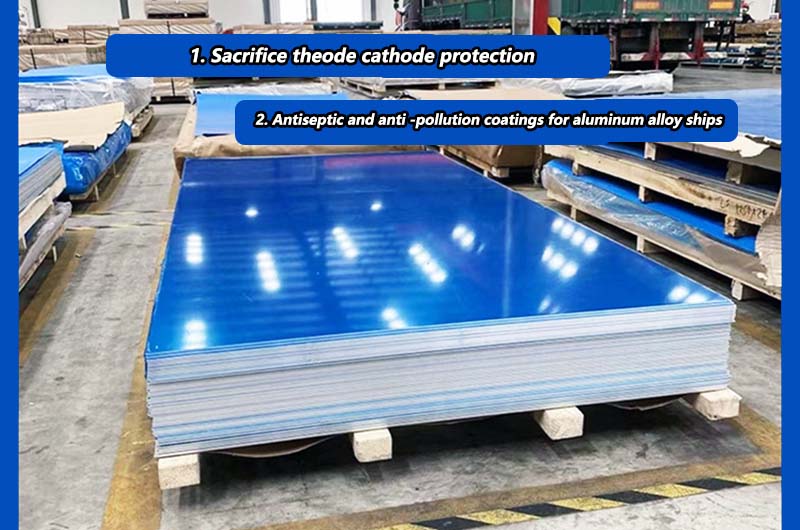

Sacrifice anode cathode protection

Setting sacrifice anode on the outer board (with anticorrosive coating), the alloy aluminum plate itself is a good sacrifice anode material compared to steel, copper and other materials.

For aluminum vessels, the aluminum aluminum plate that is sufficiently negative in electrode potential must be used to sacrifice the anode to protect it. At the same time, consider that the anode has good solubility characteristics and potential cannot be too negative, resulting in aluminum alkaline corrosion. At present, the main component of alloy aluminum plate sacrifice anode materials is Al-zN-IN-MG-TI. The sacrifice anode is fixed with bolts. The iron stamens in the anode must use aluminum stamens, and the bolts must use aluminum bolts.

Antiseptic and anti -pollution coatings for aluminum alloy ships

The corrosion environment of the bottom and water line of aluminum alloy ships is different. The bottom of the ship is mainly the infiltration and erosion effect of natural seawater and the adhesion of water organisms. The requirements for anticorrosive paint above the water line are not exactly the same.

For the parts above the waterline, the face paint should have good atmospheric aging, good gloss and decorative nature, and have good supportingness with the primer.

Haomei Aluminum produces high -quality ship aluminum plates. The ships for ships are sold for 5083 aluminum plates, 5086 aluminum plates, 5052 aluminum plates, 5059 aluminum plates, 5383 aluminum plates, 5456 aluminum plates, etc. , Haomei Aluminum products involve 1-8 series of products. The products sold in various aspects of automobiles, electronic products, and industries. For details, please consult Email: Info@alu-sheet-coil.com

Informations you may be interested in:

- 5083 5086 Aluminum plate for ship deck

- Best aluminum for salt or fresh water

- Best aluminum for marine use

- Aluminum Plate for Yachts Building

- Principles for the selection of aluminum alloy for ships

- LPG natural gas (LNG) transport ship for 5083 aluminum plate

- 9 Advantages Aluminum AlLoy in Ship Applications

- 6 proplems welding of ship aluminum

- Temper of marine aluminum alloys

- 5059 O H111 H116 H321 Marine Aluminum Plate Sheet