- 2024 aviation aluminum alloy

- 7075 aviation aluminum alloy

- 6061 aviation aluminum alloy

- 2024 7075 6061 Aerospace Aluminum Chemical Composition

- Physical and mechanical properties

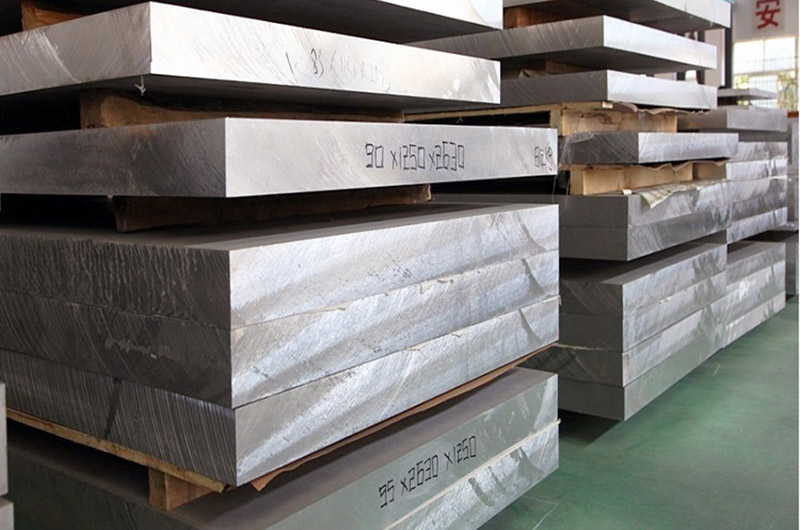

In today's aviation industry, when it comes to which material is used the most, there is no doubt that it is aluminum alloy. Typical aviation aluminum alloys are 2024 (UNS: A92024), 6061 (UNS: S96061), and 7075 (UNS: S97075).

2024 aviation aluminum alloy

2024 aluminum alloy metal Al-Cu-Mn series aluminum alloy, its advantages include excellent strength and good corrosion resistance. However, due to the copper element, 2024 aluminum alloy may have certain thermal expansion problems at high temperatures, so its application in some high-temperature environments is limited.

2024 Aerospace Aluminum Key Features

- This is a high-strength duralumin that can be strengthened by heat treatment and has medium plasticity in the quenched and freshly quenched states.

- Spot welding is good, but there is a tendency to form intergranular cracks when using gas welding. The machinability of the alloy is good after quenching and cold work hardening, but the machinability is low after annealing.

- The corrosion resistance is not high, and anodizing and painting methods are often used, or an aluminum layer is added to the surface to improve its corrosion resistance.

2024 Aerospace Aluminum Application Scope

It is mainly used to make various high-load parts and components (but not including stampings and forgings) such as aircraft skeleton parts, skins, partitions, ribs, spars, rivets and other parts working below 150℃.

7075 aviation aluminum alloy

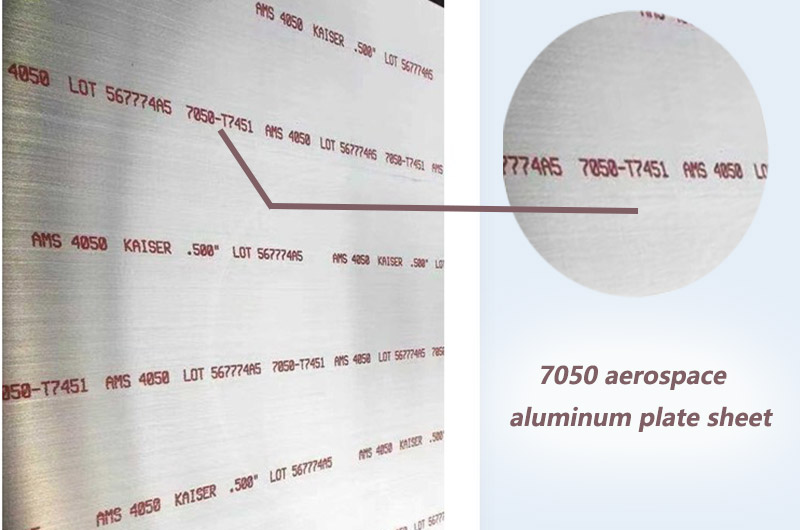

7075 aluminum alloy is an extremely high-strength aluminum alloy that is commonly used to manufacture high-strength parts in aircraft structures. Compared with 2024 aluminum alloy, 7075 alloy has more outstanding tensile strength, but sacrifices some corrosion resistance. This makes 7075 aluminum alloy more suitable for some aerospace applications that require higher lightweight and strength.

7075 Aerospace Aluminum Main Features

7075 aluminum alloy metal Al-Zn-Mg-Cu series aluminum alloy is a cold-processed forged alloy with high strength and is better than mild steel. Ordinary corrosion resistance and good mechanical properties. Fine grains enable better deep drilling performance and enhanced tool wear resistance.

Zn is the main alloy element in 7075. Adding magnesium to an alloy containing 3%-7.5% zinc can form MgZn2 with significant strengthening effect, making the heat treatment effect of this alloy far better than that of Al-Zn binary alloy. Increasing the zinc and magnesium content in the alloy will further increase the tensile strength, but its ability to resist stress corrosion and spalling corrosion will decrease.

After heat treatment, it can achieve very high strength properties. 7075 materials generally add a small amount of copper, chromium and other alloys.

7075 Aerospace Aluminum application range

Representative uses include aerospace, mold processing, mechanical equipment, and tooling fixtures. It is especially used to manufacture aircraft structures and other high-stress structures that require high strength and strong corrosion resistance.

6061 aviation aluminum alloy

6061 aluminum alloy metal Al-Mg-Si series aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Although its strength cannot be compared with 2xxx series or 7xxx series, it has many properties of magnesium and silicon alloys.

6061 Aerospace Aluminum Main Features

- Excellent processing performance

- Excellent welding characteristics and plating properties

- Good corrosion resistance, high toughness and no deformation after processing

- The material is dense, defect-free and easy to polish

- The color film is easy to apply and the oxidation effect is excellent

6061 Aerospace Aluminum application range

In the aerospace field, it is mainly used to make aircraft skins, fuselage frames, girders, rotors, propellers, fuel tanks, wall panels and landing gear struts, as well as rocket forging rings, spacecraft wall panels, etc.

6061 aluminum alloy is a versatile aluminum alloy with good processability and weldability, so it is widely used in the aviation field. Although its strength is relatively low, 6061 aluminum alloy is still an ideal choice in some areas that require better corrosion resistance and good machinability.

2024 7075 6061 Aerospace Aluminum Chemical Composition

| Attributes/Alloy | 2024 | 7075 | 6061 |

|---|---|---|---|

| (Al) | 90.7-94.7 | 90.7-91.7 | 97.9 |

| (Cu) | 3.8-4.9 | 1.2-2.0 | 0.7 |

| (Zn) | 1.2-1.8 | 5.1-6.1 | 1.0 |

| (Li) | 1.2-1.8 | 2.1-2.9 | 0.85-1.20 |

| (Fe) | 0.5 max | 0.50 max | 0.6 max |

| (Mn) | 1.3-1.8 | 0.30 max | 0.15-0.40 |

| (Mg) | 1.2-1.8 | 2.1-2.9 | 1.0-1.2 |

| (Cr) | 0.10 max | 0.18-0.28 | 0.04-0.35 |

| Other | 0.15 max | 0.20 max | 0.25 max |

Physical and mechanical properties

There may be some differences in actual application. When selecting a suitable aluminum alloy, you need to consider the specific application environment and requirements. For applications that require high strength, such as high-strength parts for aircraft structures, 7075 aluminum alloy may be a more suitable choice. For applications requiring better processability and corrosion resistance, 6061 aluminum alloy may be more suitable for some situations.

2024 7075 6061 Aerospace Aluminum Physical Properties

| Physical Property | 2024 | 7075 | 6061 |

|---|---|---|---|

| Density (g/cm³) | 2.78 | 2.78 | 2.70 |

| Melting Point (°C) | 640 | 480 | 582 |

| Coefficient of Thermal Expansion (/K) | 23.2 x 10^-6 | 23.6 x 10^-6 | 23.6 x 10^-6 |

2024 7075 6061 Aerospace Aluminum Mechanical Properties

| Mechanical Property | 2024 | 7075 | 6061 |

|---|---|---|---|

| Tensile Strength (MPa) | 470-520 | 570-700 | 275-310 |

| Yield Strength (MPa) | 325-470 | 505-600 | 240-280 |

| Elongation (%) | 20 | 11 | 8 |

| Hardness (HB) | 120 | 150 | 95 |

Different aviation aluminum alloys are suitable for different scenarios and needs. When selecting a suitable aluminum alloy, aluminum plate manufacturers need to consider factors such as strength, corrosion resistance, and thermal performance. For parts requiring extremely high strength, 7075 aluminum alloy may be the first choice.

By gaining a deeper understanding of the performance characteristics of various aviation aluminum alloys, manufacturers can better optimize aircraft structures and improve overall performance and safety.

Informations you may be interested in: