- Characteristics of aluminum coils for thermal insulation

- Precautions for storage of thermal insulation aluminum coils

Aluminum coil for thermal insulation is a kind of thermal insulation material commonly used in construction and industrial fields. Aluminum coil for thermal insulation is mainly divided into two series: pure aluminum coil and 3003 aluminum coil. At present, most thermal insulation projects are based on 3003 aluminum coils, and the price gap between them and pure aluminum coils is not very big.

3003 thermal insulation aluminum coil has better corrosion resistance. For some corrosive gas and liquid pipelines, this material needs to be used. Pure aluminum thermal insulation aluminum coils are suitable for engineering applications with low requirements and no corrosive liquids, and the use cost is relatively low.

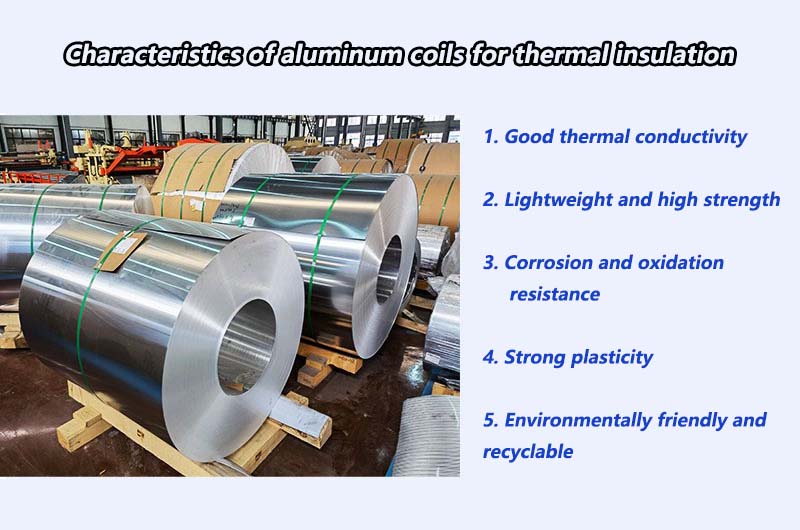

Characteristics of aluminum coils for thermal insulation

1. Good thermal conductivity

As an insulation material, one of its distinctive features is its excellent thermal conductivity. Aluminum itself is an excellent thermal conductive material that can efficiently conduct or insulate heat and plays a vital role in building insulation systems. Its thermal conductivity not only helps maintain indoor temperature stability, but also effectively improves energy efficiency.

2. Lightweight and high strength

The light weight and high strength of aluminum make aluminum coils widely used in construction and industrial fields. Compared with other metals, aluminum coils are relatively lightweight and easy to carry and install. At the same time, aluminum’s exceptional strength and ability to provide structural support make it outstanding in a variety of construction applications.

3. Corrosion and oxidation resistance

Aluminum coils exhibit good corrosion resistance and oxidation resistance. Aluminum has natural anti-corrosion properties and is not easily corroded by environmental factors such as atmosphere, moisture, acid and alkali. In addition, an aluminum oxide film usually forms on the aluminum surface, further enhancing its oxidation resistance and extending its service life.

4. Strong plasticity

Aluminum material has excellent plasticity and can achieve diverse shapes through various processing techniques, such as rolling, drawing, etc. This enables aluminum coils to adapt to the needs of different building structures and flexibly respond to various design and installation requirements.

5. Environmentally friendly and recyclable

Rising environmental awareness has made sustainability an important consideration in material selection. Aluminum is a recyclable material, the recycling process is relatively simple and reduces reliance on natural resources. Choosing aluminum coils as insulation material helps reduce environmental impact and is in line with the concept of sustainable development.

Precautions for storage of thermal insulation aluminum coils

During the construction process, the thermal insulation aluminum coils cannot be used up in a short time and need to be properly kept. If the thermal insulation aluminum coils are not placed in a dry warehouse, once rainfall occurs, the acidic substances in the rainwater will cause the oxidation of the thermal insulation aluminum coils. It is said to be a huge loss, so you must pay more attention to the storage of thermal insulation aluminum coils.

1. Moisture-proof and moisture-proof

Aluminum coils need special attention to moisture-proofing during storage. Moisture may affect the performance of aluminum, so it is recommended to store aluminum coils in a dry and ventilated environment. Consider using moisture-proof agents to ensure dryness of the storage environment.

2. Handle with care and avoid collisions

When handling and storing aluminum coils, be sure to handle them with care and avoid collision with heavy objects. Due to the plasticity of aluminum, it is prevented from being deformed or damaged by external forces.

3. Keep away from acid and alkali substances

Aluminum coils should be kept away from acid and alkali substances to avoid chemical reactions leading to corrosion. Storage areas should be kept clean and free of contact with chemicals that may cause corrosion.

4. Avoid high temperature environment

High temperature environments may affect the performance and shape of aluminum coils. Therefore, aluminum coils should be avoided in high temperature environments during storage, especially direct sunlight.

5. Regular inspections

Regularly checking the storage conditions of aluminum coils is an important step to ensure the stability and reliability of their performance. Check regularly for moisture accumulation, odor and other abnormalities, and take timely measures.

The common thickness of thermal insulation aluminum coils is mostly below 1mm, and common thicknesses are 0.5mm, 0.6mm, 0.8mm, and 1.0mm. The width is 1 meter wide.

The above is a more detailed description of the characteristics and storage precautions of aluminum coils for thermal insulation. This information helps ensure that aluminum coils can fully exert their superior properties during use and storage and maintain long-term stability.

Informations you may be interested in:

- 0.5mm thick 3003 anti-corrosion thermal insulation aluminum coil

- Aluminum Coil for Power Plant Insulation

- Stucco embossed aluminum coil for pipe insulation

- What precautions should be taken when applying thermal insulation aluminum coils?

- What are the benefits of aluminum insulation?

- Is aluminum a good thermal insulator?

- 1050 thermal insulation aluminum coil