- Marine Aluminum Alloy Selection

- Aluminum surface treatment in salt water or fresh water environments

- Aluminum selection considerations for saltwater or freshwater environments

The marine environment includes various types of waters, mainly divided into freshwater environments and saltwater environments. Freshwater and saltwater environments have different corrosion properties for materials, so it is crucial to choose an aluminum alloy suitable for marine environments.

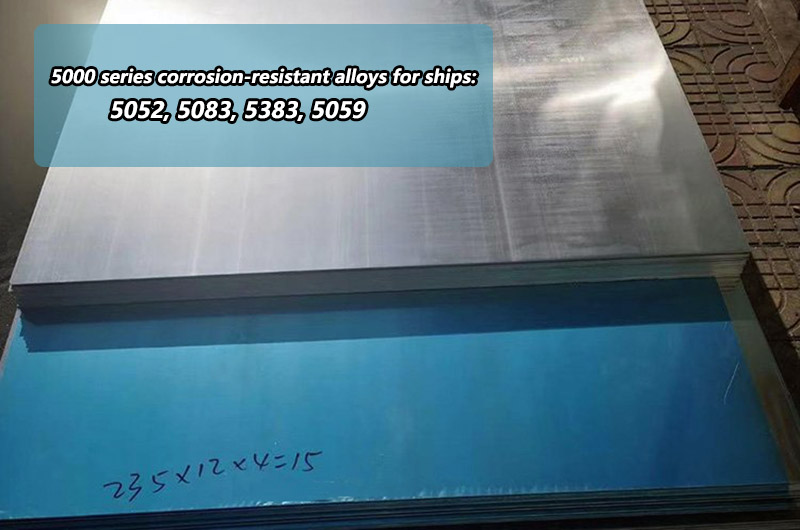

Aluminum alloys behave differently in salt water environments or salty atmospheres. In this case, the alloys with the best corrosion resistance belong to the 5000 series (5052, 5083, 5383, 5059) and the 6000 series (6082, 6005A, 6063).

Freshwater environment

- River: Freshwater rivers that flow from land to ocean, mixing with seawater as they flow through coastal areas.

- Lake: An inland freshwater lake with no direct connection to the ocean.

- Freshwater wetlands: Such as swamps, swamps, wetlands, etc., where the water is usually freshwater.

salt water environment

- Ocean: Saltwater environments around the world, including oceans and bays.

- Saltwater lakes: The water in some inland lakes contains high salt content, forming saltwater lakes.

When selecting marine aluminum in fresh and salt water environments, consider the material's corrosion resistance, seawater resistance and performance.

Marine Aluminum Alloy Selection

best aluminum for fresh water

In freshwater environments, general aluminum alloys perform well, such as 6000 series aluminum alloys (such as 6061 and 6063). They have better corrosion resistance and mechanical properties.

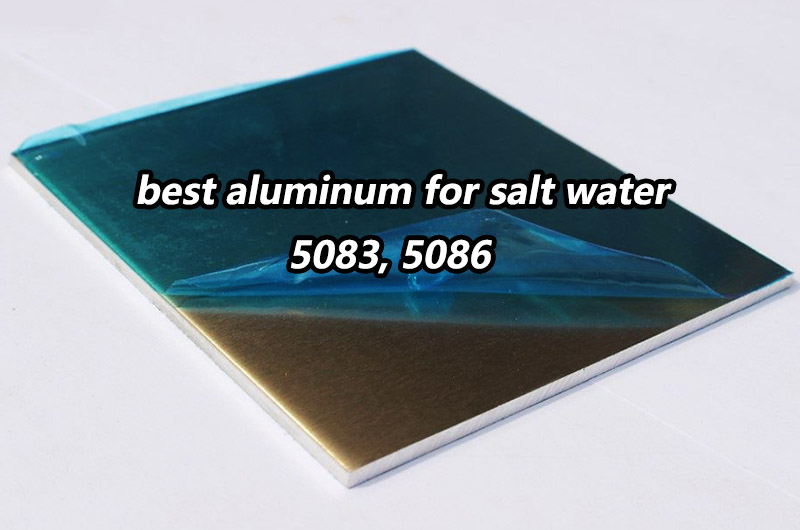

best aluminum for salt water

In salt water environments, it is best to choose aluminum alloys with higher corrosion resistance, such as the 5000 series (such as 5083 and 5086) or the 7000 series. These alloys generally have better resistance to seawater corrosion.

- 5083 Aluminum Alloy: 5083 aluminum alloy is a premium marine grade aluminum alloy with good corrosion resistance and high strength. It is particularly suitable for hull structures, ship plating and other components requiring high strength and corrosion resistance.

- 5086 aluminum alloy: 5086 aluminum alloy is similar to 5083 and also has good corrosion resistance and high strength. It is applied to the hull, decking and other structural components of ships.

Both aluminum alloys belong to the 5000 series, which are characterized by good corrosion resistance, especially in salt water environments such as seawater. They also perform well in welding properties and are suitable for manufacturing hull structures requiring complex shapes.

Aluminum surface treatment in salt water or fresh water environments

- Freshwater environment: In freshwater, anti-corrosion coatings can be considered to increase the corrosion resistance of aluminum alloy surfaces.

- Salt water environment: In salt water environments, it is best to choose aluminum alloys with seawater corrosion-resistant surface treatments. Some use anodized layers to resist seawater corrosion or other special anti-corrosion treatments.

Aluminum selection considerations for saltwater or freshwater environments

1. Alloy strength and weight

- Freshwater environments: In freshwater environments, strength requirements may be lower, so lighter aluminum alloys may be selected to reduce the weight of the vessel.

- Saltwater Environments: In saltwater environments, higher strengths are often required due to ocean conditions. Therefore, stronger aluminum alloys can be selected to ensure the structural performance and durability of the boat.

2. Anti-corrosion coating

Whether in fresh water or salt water environments, in order to improve the corrosion resistance of aluminum alloys, anti-corrosion coatings can be considered. These coatings can provide additional protection and extend the service life of aluminum alloys in marine environments.

When making the actual selection, the specific application and design requirements will determine the most appropriate type of aluminum alloy, ensuring that the chosen aluminum alloy meets the requirements of the specific environment.

- Freshwater Environment: In a freshwater environment, boat maintenance may be relatively painless, but regular cleaning and maintenance will still be required to extend the life of the hull.

- Salt water environment: In salt water environments, more frequent cleaning and anti-corrosion treatments are essential to prevent seawater corrosion of aluminum alloys.

Informations you may be interested in:

- 5083 5086 Aluminum plate for ship deck

- Best aluminum for marine use

- Aluminum Plate for Yachts Building

- Principles for the selection of aluminum alloy for ships

- LPG natural gas (LNG) transport ship for 5083 aluminum plate

- 9 Advantages Aluminum AlLoy in Ship Applications

- 6 proplems welding of ship aluminum

- How to treat corrosion treatment for boat aluminum plates?

- Temper of marine aluminum alloys

- 5059 O H111 H116 H321 Marine Aluminum Plate Sheet