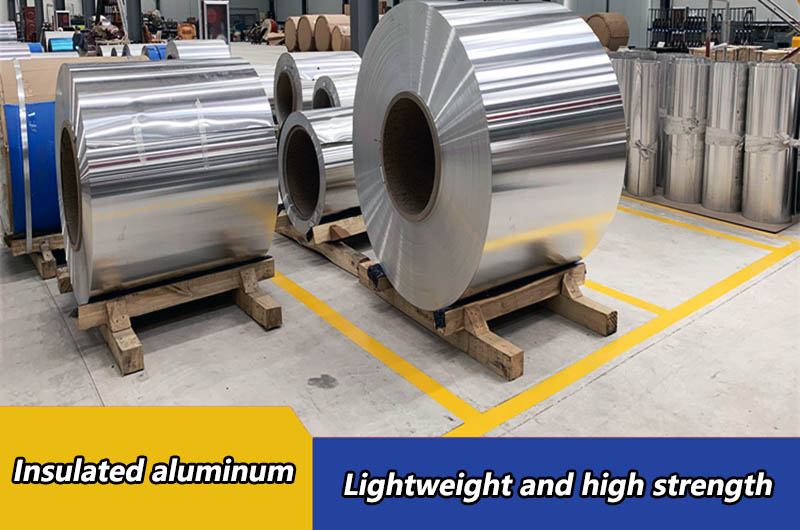

- Lightweight and high strength

- Excellent electrical conductivity

- Strong corrosion resistance

- The price is relatively low

- recyclability

- Good heat dissipation

- Easy to process

- Reliability and durability

In power transmission and distribution systems, aluminum insulation materials are a common choice for cables and wires and are widely used for their many advantages. In the following pages, we will explore in detail the various advantages of aluminum insulation materials, from light weight and high strength to recyclability.

Lightweight and high strength

Aluminum is a relatively lightweight metal with a low density. This makes aluminum insulation relatively lightweight, especially suitable for applications where equipment weight is sensitive. In projects such as overhead power lines and long-distance power transmission lines, the use of aluminum insulation materials can reduce weight and reduce the burden on support structures, thereby reducing construction and maintenance costs.

Excellent electrical conductivity

Aluminum has good electrical conductivity, although it is slightly inferior to copper, but it is sufficient to meet the requirements of power transmission in many application scenarios. Aluminum's electrically conductive properties make it a viable alternative, especially in projects where weight and economy are critical, where aluminum insulation can provide good performance.

Strong corrosion resistance

Aluminum has excellent corrosion resistance and can withstand humidity, atmospheric chemicals, and other corrosive factors. This makes aluminum insulation perform well outdoors, in humid environments, and in locations where there is a risk of corrosion, such as chemical plants. The strong corrosion resistance of aluminum insulation materials enables them to maintain good electrical properties during long-term use.

The price is relatively low

Aluminum is one of the most abundant metals on earth. Compared with rare metals such as copper, aluminum has a lower raw material cost. In some large-scale electrical engineering projects, the use of aluminum insulation materials can effectively reduce material procurement costs. This advantage makes aluminum an ideal choice for projects with limited budgets.

recyclability

Aluminum is a recyclable material that helps reduce reliance on natural resources while reducing waste generation. This is in line with modern society's pursuit of sustainable development and environmental protection. The use of recyclable aluminum insulation materials helps reduce resource consumption and promote the development of a circular economy.

Good heat dissipation

Aluminum has good thermal conductivity properties and helps dissipate heat. This is especially important in high-power equipment and power systems, helping to prevent equipment from overheating and improving equipment stability and life. Good heat dissipation properties make aluminum insulation an ideal choice in some temperature-sensitive applications.

Easy to process

Aluminum materials are relatively easy to process into various shapes to adapt to the design needs of various electrical equipment. This flexibility makes aluminum insulation more malleable when manufacturing and customizing cables. Designers can more easily implement different shapes and sizes of cables to suit specific application scenarios.

Reliability and durability

Aluminum insulation materials show high reliability and durability over long periods of use. Its combination of corrosion resistance, electrical conductivity and mechanical strength enables aluminum insulation materials to adapt to various harsh environmental conditions and maintain stable electrical performance.

Due to its multiple advantages, aluminum insulation materials are widely used in different fields, including construction, power engineering, transportation, etc. Aluminum insulation materials have excellent performance in power transmission lines, household appliances, cable communications, etc.

Generally speaking, aluminum insulation materials have become one of the most favored materials in the field of power engineering due to their multiple advantages such as light weight, high strength, excellent electrical conductivity, and strong corrosion resistance.

In practical applications, these advantages need to be fully weighed to make the best choice based on the requirements and environmental conditions of the specific project. The continuous improvement and innovation of aluminum insulation materials will also promote its wider application in the future.

Informations you may be interested in:

- 0.5mm thick 3003 anti-corrosion thermal insulation aluminum coil

- Aluminum Coil for Power Plant Insulation

- Stucco embossed aluminum coil for pipe insulation

- What precautions should be taken when applying thermal insulation aluminum coils?

- Characteristics and storage precautions of aluminum coils for thermal insulation

- Is aluminum a good thermal insulator?

- 1050 thermal insulation aluminum coil