- Automobile inspection tools

- Automobile fixture

- Automobile inspection tool and fixture 5005 aluminum plate features

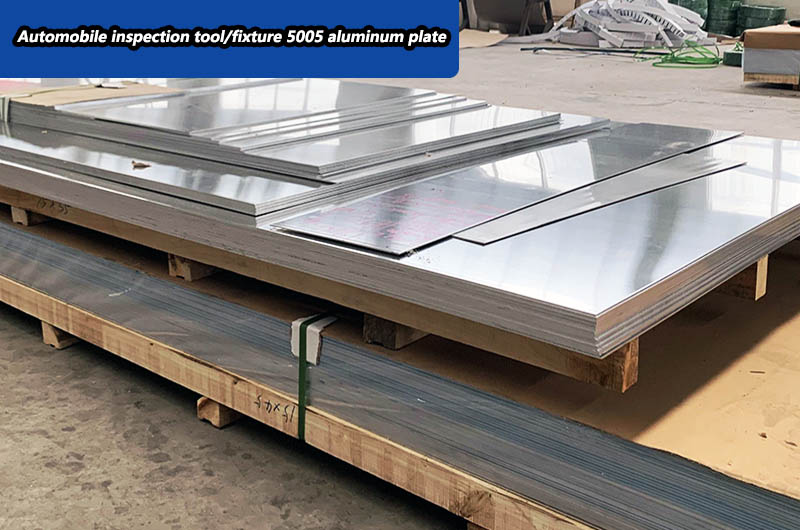

- Aluminum Selection 5005 Aluminum Plate for Automotive Inspection Tools and Fixtures

- Applications of 5005 aluminum plate in automobile inspection tools and fixtures

With the rapid development of the automobile industry, all aspects of automobile manufacturing are constantly pursuing higher efficiency and more precise processes. In the process of automobile production, the quality of automobile inspection tools and fixtures is crucial to the accuracy and quality of the product.

Automotive inspection tools and fixtures are tools used in the automobile manufacturing and repair process. They play a key role in ensuring the accuracy, quality and safety of automobile parts. The concepts and functions of these two tools are introduced below:

Automobile inspection tools

- Definition: Automobile inspection tools are tools used to detect, measure and verify the size, shape and characteristics of automobile parts. They usually include various measuring tools, gauges, calipers, coordinate measuring machines and other equipment.

- Function: Mainly used to ensure the accuracy and quality of automobile parts during the manufacturing and assembly process. By using inspection tools, manufacturers can check that components meet design specifications, ensuring that the final assembled vehicle meets expected performance and safety standards.

Automobile fixture

- Definition: An automotive fixture is a device used to hold and position automotive parts for machining, assembly and other process operations. Grips can be mechanical, hydraulic, or pneumatic, and their designs vary based on specific operating needs.

- Function: Mainly used to ensure the accurate positioning and fixation of automobile parts during the manufacturing and assembly process. The fixture can ensure that the parts do not move or deform during processing, thereby ensuring the processing accuracy of the parts and the quality of the final assembly.

The two tools work closely together in automotive manufacturing, with gauges used to verify the quality and dimensions of parts and jigs used to stably hold parts in place during manufacturing and assembly. Their correct use can improve production efficiency, ensure product quality, and reduce manufacturing costs.

Automobile inspection tool and fixture 5005 aluminum plate features

- Chemical composition: 5005 aluminum plate is mainly composed of aluminum, magnesium, and a small amount of manganese, and has excellent corrosion resistance.

- Strength and toughness: 5005 aluminum plate has medium strength and good toughness, and is suitable for manufacturing inspection tools and fixtures that require high precision and stability.

- Surface treatment: 5005 aluminum plate can undergo various surface treatments, such as anodizing, coating, etc., to enhance its corrosion resistance and aesthetics.

- Processing performance: 5005 aluminum plate is easy to process and form, and is suitable for manufacturing various complex shapes and structures.

Aluminum Selection 5005 Aluminum Plate for Automotive Inspection Tools and Fixtures

The advantages of aluminum plates for automobile inspection tools and fixtures are that the fixtures are light in weight and easy to operate. The alloys can be 5 series and 6 series products. 5005 aluminum plate is a good product.

- Typical alloy: 5005 aluminum plate

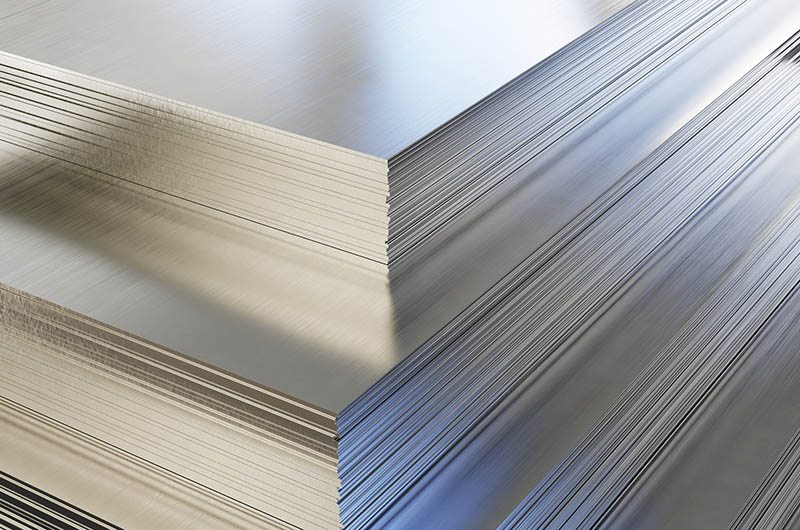

- Material status O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114, H 116, H321

- Thickness (mm): 0.15-600

- Width (mm): 20-2650

- Length (mm): 500-16000

Applications of 5005 aluminum plate in automobile inspection tools and fixtures

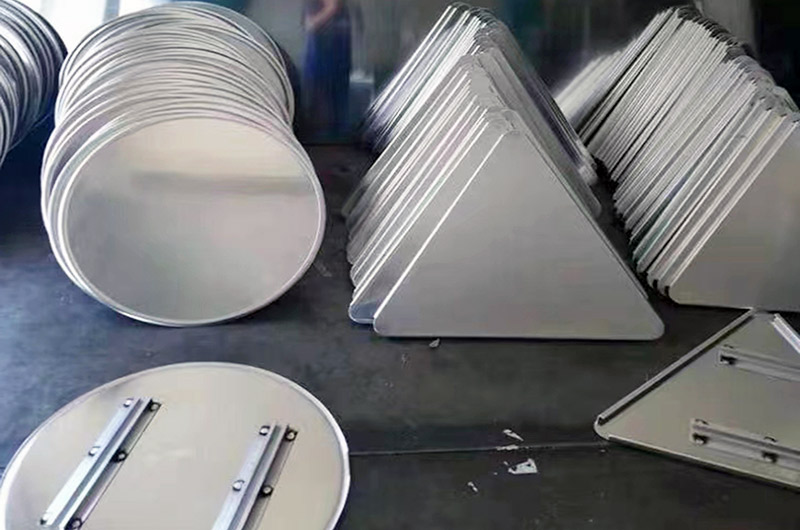

Manufacturing inspection tools: Because 5005 aluminum plate has good processing performance and stability, it can be used to manufacture various automotive inspection tools, such as fixtures, measuring tools, measuring tools, etc. Its lightweight nature also makes the inspection tool easier to carry and operate.

- Clamp manufacturing: 5005 aluminum plates can be used to manufacture clamps to hold automotive parts during processing and assembly during the production process. The accuracy and stability of fixtures are crucial to ensuring the quality of automotive parts and the accuracy of assembly.

- Body mold: In automobile production, the accuracy of the body mold has an important impact on the appearance and safety of the vehicle. 5005 aluminum plate can be used to manufacture body molds to ensure its accuracy and stability while reducing the weight of the overall mold.

- Workshop equipment brackets: 5005 aluminum plates can also be used to manufacture workshop equipment brackets, providing support and stability while reducing the weight of the overall equipment and facilitating workshop layout and maintenance.

As a high-quality material, 5005 aluminum plate has the potential to be widely used in automobile inspection tools and fixture manufacturing. Its properties include excellent corrosion resistance, moderate strength and good processability, making it ideal for manufacturing automotive parts with high precision and stability.

In the automobile manufacturing process, rational use of 5005 aluminum plates can improve production efficiency and reduce costs, while ensuring the quality and safety of automobile products.

Informations you may be interested in: