- Why choose aluminum board for boat shipbuilding ships

- Yacht ship aluminum board selection

- Specification of Marine Grade Aluminum Sheets

- Aluminum plate applications for yacht construction

Yacht is a kind of durable consumer goods for water entertainment. It integrates navigation, sports, entertainment, leisure and other functions to meet the needs of individuals and families to enjoy life.

The use of aluminum plates in yachts is a common choice, because aluminum has many advantages, making it a popular material in the ship manufacturing industry.

Why choose aluminum board for boat shipbuilding ships

- 1. Lightweight high strength: Aluminum alloy is lighter and higher than traditional ship materials such as steel. This makes the hull structure lighter and helps improve the speed and fuel efficiency of yachts.

- 2. Strong corrosion resistance: Aluminum alloy has strong corrosion resistance, and has good corrosion resistance to seawater and humidity. This is crucial for yachts that have been running at sea for a long time, because the seawater is very corrosive.

- 3. Easy processing: Aluminum alloy has good processability, and it is easy to mold and weld. This makes the shipbuilding process more flexible and can produce more complicated and customized designs.

- 4. Low maintenance costs: Aluminum alloy has low maintenance costs because it is not easy to rust, and it does not need to be rusted frequently as other materials during maintenance.

- 5. Good thermal conductivity: Aluminum alloy has good thermal conductivity, which helps to better maintain the stability of the hull structure under extreme temperature conditions.

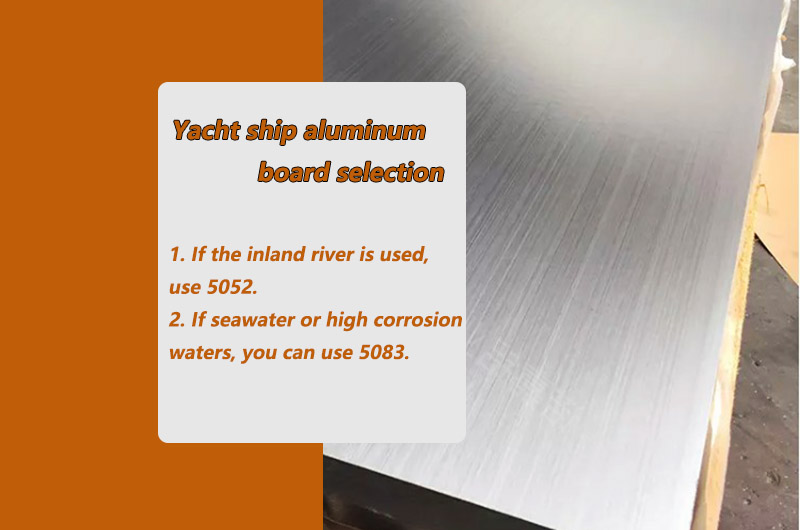

Yacht ship aluminum board selection

Generally, the shipping level is aluminum alloy, and mostly refers to the magnesium aluminum alloy of 5 Series. 5052 Magnesium contains less and has good molding performance, and is better for pressure. The high point of 5083 is more crispy and not suitable for voltage processing, but 5083 is better than 5052 hard and anticorrosive performance.

In most cases, in order to adapt to the environment and beauty of the seawater, aluminum alloy boats will use 5083 to do the lower part of the boat (underwater part) and 5052 as the upper part of the boat (surface part).

5083 aluminum plates are widely used in various ships, such as small fishing vessels, yachts, speedboats, giant wheels, etc. Because the material has excellent welding, formability, and corrosion resistance, it has been successfully used on the side of the ship and the bottom of the ship. Board, keel, ribs, engine table seats, cigarette cylinders, masts, etc.

Aluminum alloy yacht material selection:

- 1. The loading also uses 5052 alloys, the variety is plate, tube and stick.

- 2. 5083 alloys can produce wide -squeezing profiles.

Specification of Marine Grade Aluminum Sheets

| Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) |

|---|---|---|---|---|

| 5052 |

F, O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, H114 |

3-50 | 20-2650 | 500-16000 |

| 5083 |

O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34 H36, H38, H111, H112, H114, H 116, H321 |

3-50 | 20-2600 | 500-16000 |

Aluminum plate applications for yacht construction

- Boat Body: The main structure of the yacht is usually composed of hull, and the vessel aluminum plate is often used in the manufacturing of the hull. Its lightweight and high intensity features make the hull lighter and can provide sufficient structural strength, thereby achieving high -speed and efficient navigation.

- Superstructure of Yacht: The upper layers of the yacht include various cabins, decks, and stern platforms on the boat. The easy processing of marine aluminum plate enables designers to create complex structures more freely, while lightweight characteristics help maintain the stability of the boat.

- Deck of a Vessel: The deck of the yacht needs to have sufficient strength to bear the effects of the load on the boat and the external environment. The high intensity of the ship's aluminum plate makes the deck more durable, and the characteristics of corrosion resistance will help cope with the impact of seawater and weather.

- Superstructure of Yacht: The internal space of the yacht includes the cabin, the cabin, and the equipment house. Ship aluminum plates can be used to build these internal structures and provide lightweight, sturdy and corrosion -resistant characteristics for the cabin.

Ship aluminum plates are mainly used to build hulls and related structures in yacht manufacturing to meet the requirements of light quality, high strength, and corrosion resistance to ensure that yachts have good performance and durability.

Informations you may be interested in:

- 5083 5086 Aluminum plate for ship deck

- Best aluminum for salt or fresh water

- Best aluminum for marine use

- Principles for the selection of aluminum alloy for ships

- LPG natural gas (LNG) transport ship for 5083 aluminum plate

- 9 Advantages Aluminum AlLoy in Ship Applications

- 6 proplems welding of ship aluminum

- How to treat corrosion treatment for boat aluminum plates?

- Temper of marine aluminum alloys

- 5059 O H111 H116 H321 Marine Aluminum Plate Sheet