- Advantages of yogurt covered with aluminum foil

- Which alloy is suitable for making yogurt lid aluminum foil?

- Conclusion

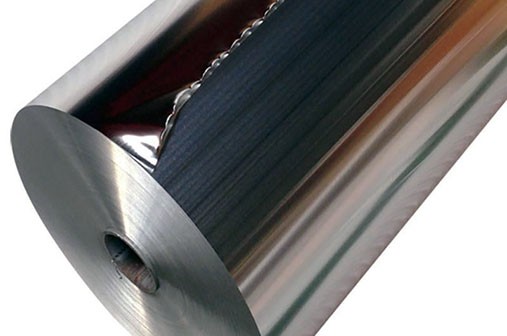

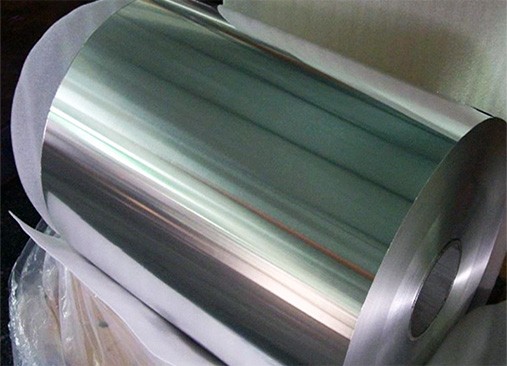

Aluminum foil has become an indispensable material in various industries, and one of its noteworthy applications is the production of yogurt lids. The thin, flexible metal sheet offers a range of advantages that help make yogurt packaging more efficient, safe and attractive

Advantages of yogurt covered with aluminum foil

1. Barrier performance

One of the main advantages of aluminum foil is its excellent barrier properties. It acts as a protective shield against light, oxygen, moisture and contaminants, maintaining the freshness and quality of the yogurt. This barrier helps prevent spoilage, preserve flavor and extend the shelf life of the product.

2.Heat resistance

Aluminum foil is heat-resistant, making it an ideal material for sealing yogurt containers. The foil can withstand the high temperatures during pasteurization and hot filling without compromising its integrity. This ensures that the yogurt is free from contamination and is safe to eat.

3. Sealing effect

The malleability and conformability of aluminum foil allows for a tight and secure seal on the yogurt cup. This effective seal minimizes the risk of leaks and spills, protecting the product during transportation and storage. Consumers appreciate the convenience and cleanability of well-sealed yogurt containers.

4. Printability and branding

Aluminum foil provides an excellent surface for printing vibrant, high-quality graphics, allowing brands to display their logos, product information and other promotional content. This helps increase brand recognition and enhances the visual appeal of the yogurt packaging on store shelves.

5. Recyclability

Aluminum foil is an eco-friendly option and is highly recyclable. Aluminum’s recyclability reduces the environmental impact of packaging waste, in line with the food industry’s growing demand for sustainable and environmentally friendly packaging solutions.

6. Cost-effective production

Aluminum foil is cost-effective in terms of production and material costs. Its lightweight nature reduces shipping costs, and its efficiency in maintaining product freshness helps manufacturers and retailers save costs.

7. Easy to use

The yogurt lids made of aluminum foil are easy to peel off, providing consumers with a hassle-free experience. The convenience of opening and resealing containers enhances the overall user experience, helping to increase customer satisfaction and loyalty.

8. Customization options

Manufacturers can easily customize foil yogurt lids to meet specific design and branding requirements. This flexibility allows creative packaging solutions to stand out in a competitive market and capture consumers' attention.

Which alloy is suitable for making yogurt lid aluminum foil?

The choice of alloy plays a crucial role in determining the performance and characteristics of aluminum foil for yogurt lids. There are a variety of alloys suitable for this application, each offering unique properties to meet the specific needs of yogurt packaging. The following alloys are commonly used in the manufacture of yogurt lidding foil:

1. 8011 Aluminum foil for yogurt lid

Alloy 8011 is an aluminum alloy widely used in food packaging, including yogurt lids. Its excellent formability ensures that the foil can be easily formed and sealed onto the yogurt container. 8011 alloy also has high tensile strength and tear resistance, which helps improve the durability of the cover during production and use.

Suitability:

- Excellent formability, making it easy to shape and seal onto yogurt containers.

- High tensile strength and tear resistance for durability during production and use.

Applications:

- Commonly used for yogurt lids in standard packaging where a balance of formability and strength is essential.

- Suitable for applications where cost-effectiveness is a primary concern.

2. 8079 Aluminum foil for yogurt lid

Alloy 8079 is another aluminum alloy known for its suitability for food packaging applications. It provides a higher level of moisture and gas barrier protection, making it ideal for yogurt lids where preservation is crucial. The corrosion resistance of Alloy 8079 further increases the service life of the foil.

Suitability:

- High barrier protection against moisture and gases, preserving freshness.

- Excellent corrosion resistance.

Applications:

- Ideal for yogurt lids in premium packaging where extended shelf life and superior barrier properties are crucial.

- Suitable for products that are sensitive to environmental factors and require enhanced protection.

3. 1200 Aluminum foil for yogurt lid

Alloy 1200 is characterized by high thermal conductivity and excellent corrosion resistance. While not as commonly used as alloys 8011 or 8079, alloy 1200 may be suitable for yogurt lids in specific applications where these properties are particularly beneficial.

Suitability:

High thermal conductivity and excellent corrosion resistance.

Applications:

- Suited for yogurt lids in applications where heat dissipation is important.

- Used in specialized packaging where corrosion resistance is a primary consideration.

4. 1235 Aluminum foil for yogurt lid

Alloy 1235 is known for its purity and formability. It is frequently used in the production of flexible packaging, including aluminum foil for yogurt lids. The high aluminum content in Alloy 1235 contributes to its excellent barrier properties, protecting the yogurt from external factors that could compromise its quality.

Suitability:

- Purity and formability are key characteristics.

- High aluminum content for exceptional barrier properties.

Applications:

- Ideal for yogurt lids where purity is crucial, such as organic or premium products.

- Commonly used in flexible packaging where formability and barrier protection are critical.

5. 3003 Aluminum foil for yogurt lid

Alloy 3003 is a non-heat treatable alloy with good corrosion resistance and formability. While not as common as the previously mentioned alloys in yogurt lid applications, it may find use in specific situations where its properties are beneficial.

Suitability:

Good corrosion resistance and formability.

Applications:

- Suited for yogurt lids in specific applications where corrosion resistance is a priority.

- Used in situations where the alloy's properties align with the packaging requirements.

Conclusion

In summary, using aluminum foil for yogurt lids brings many advantages to the table. From barrier properties to heat resistance, printability and recyclability, aluminum foil plays a vital role in ensuring the quality, safety and marketability of yogurt products.

As demand for convenient, sustainable and visually appealing packaging continues to rise, the versatile properties of aluminum foil make it the material of choice for yogurt manufacturers looking to meet consumer expectations and industry standards.