- What is Double Zero Aluminum Foil?

- Characteristics of double zero aluminum foil

- Typical Double Zero Aluminum Foil Specifications

- Double zero foil application areas

- Double Zero Aluminum Foil stickiness problem

- Conclusion

Aluminum foil has become an integral part of our daily lives and has many uses in cooking, packaging and insulation. Among the various types of aluminum foil, Double Zero aluminum foil stands out as a remarkable innovation in this field.

Aluminum foil classification:

- Thick foil is called heavy gaugefoil.

- Single zero foil is called medium gaugefoil.

- Double zero foil is called lightgaugefoil.

- Aluminum foil with thickness ≤40ltm is called light gauge foil.

- Aluminum foil with thickness >40btm is collectively called heavy gaugefoil.

What is Double Zero Aluminum Foil?

Double-zero foil refers to aluminum foil with two zeros after the decimal point when the thickness is measured in millimeters. For example:

- 0.006 mm Aluminum Foil

- 0.007 mm Aluminum Foil

- 0.008 mm Aluminum Foil

- 0.009 mm Aluminum Foil

The above are called double zero aluminum foil.

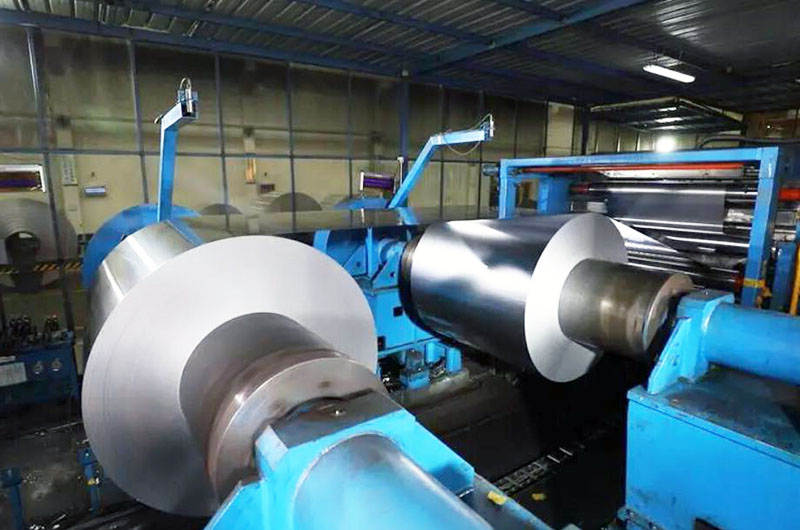

Currently, in addition to electrolytic capacitors, more than 90% of packaging aluminum foil uses double-zero aluminum foil. This foil can be laminated with paper or other materials to create packaging for tobacco and food.

Double Zero Aluminum Foil is a special type of aluminum foil known for its exceptional thickness and quality. Double Zero aluminum foil is much thinner than standard aluminum foil. This extremely thin nature results in unique properties and applications.

Characteristics of double zero aluminum foil

1. Ultra-thin structure

The most notable feature of Double Zero aluminum foil is its ultra-thin structure. About 1/3 of ordinary aluminum foil, this property is flexible and malleable, making it suitable for a variety of applications.

2. High purity

Double Zero aluminum foil is made of high-purity aluminum to ensure that the material is free of impurities. This purity contributes to the foil’s strength, durability and corrosion resistance.

3. Excellent barrier properties

The thinness of Double Zero aluminum foil does not affect its barrier properties. It has an excellent light, moisture, gas and odor barrier, making it ideal for packaging sensitive products.

4. Heat resistance

Double Zero aluminum foil exhibits excellent heat resistance. This property makes it suitable for applications involving high temperatures, such as baking, grilling, and even industrial processes.

5. Conductivity

Despite being thin, Double Zero aluminum foil maintains good thermal conductivity. This makes it suitable for applications requiring efficient heat transfer, such as the food industry.

Typical Double Zero Aluminum Foil Specifications

| Type | Double Zero Foil for Lamination |

|---|---|

| Application | Cigarette Packaging, Lamination and Food Packaging |

| Alloy Type | 1235, 8011 |

| Tempe | O |

| Thickness & Tolerance | 0.006~0.009 MM (Tolerance =±6%) |

| Width & Tolerance | 280MM -1300MM (Tolerance: 1MM) |

| Typical Core I.D. | 76 MM , 152 MM |

| Inner Core Materials | Steel, Aluminum core |

| Mechanical Properties | Tensile Strength(U.T.S): 35 MPA – 100 MPA |

| Elongation not less than 0.5% | |

| Adopted Standard | GB3198(China National Standard) |

| Package: | Seaworthy Export Standard Wooden Box |

Special specifications can be provided according to customer requirements. The following are the aluminum foil specifications often provided by Haomei Aluminum.

| Aluminum Type |

Thickness (MM) |

Alloy Type | Temper |

Width (MM) |

Core I.D. (MM) |

| Double zero foil for lamination | 0.006-0.009 | 1235 8011 | O | 280-1300 |

76 152 |

| Household Aluminum foil | 0.010-0.020 | 8011 | O | 200-600 |

76 152 |

| Pharmaceutical aluminum foil | 0.020-0.030 |

1235 8011 |

O H18 |

200-1300 |

76 152 |

| Container aluminum foil | 0.03-0.12 |

3003 8011 |

H22 H24, H18, O | 200-1000 |

76 152 |

| Insulation aluminum foil | 0.01-0.08 | 8011 1050 | O | 900-1100 |

76 152 |

| Fin stock aluminum foil | 0.1-0.105 | 8011, 1100 1200 |

H22 H24 H26 |

270-1300 | 150, 200 505 |

Double zero foil application areas

Double-zero aluminum foil is relatively thin and is mainly used in the packaging industry, such as food packaging, cigarette packaging, etc.

1. Double Zero Aluminum Foil for packaging industry

Double Zero aluminum foil is widely used in the packaging industry due to its excellent barrier properties. It is commonly used for packaging of pharmaceuticals, food and sensitive electronic components. Foil acts as a protective layer, maintaining the freshness and integrity of packaged goods.

2. Cooking and Baking

Double Zero aluminum foil's heat resistance and even heat distribution properties make it a primary material for cooking and baking. It is widely used for packaging and cooking a variety of foods, from vegetables to meat, and is even used in bags for making delicate dishes.

3. Insulation

Due to its thin yet effective barrier properties, Double Zero aluminum foil is used in insulation applications. It is used in residential and industrial settings to insulate walls, roofs and HVAC systems, reflect heat and increase energy efficiency.

4. Electronics and Technology

The high purity of Double Zero aluminum foil makes it suitable for applications in the electronics and technology sectors. It is commonly used to produce capacitors, batteries, and other electronic components that require pure, thin conductive materials.

5. Medicines

In the pharmaceutical industry, double-zero aluminum foil is the material of choice for blister packaging. It is moisture-proof, light-proof and gas-proof, ensuring the stability and shelf life of medicines.

6. Decoration and Art

The versatility of Double Zero foil extends to artistic applications. Due to its flexibility and reflective surface, artists and craftsmen use it to create sculptures, paintings and intricate designs.

Double Zero Aluminum Foil stickiness problem

Double Zero aluminum foil sticking (tackiness) issues especially in the soft state after annealing. Double Zero foil adhesion issues can be caused by two main factors:

- 1. The mechanical properties of aluminum foil are insufficient for the intended use.

- 2. The oil removal effect on the surface of aluminum foil is not good.

Solutions to the sticky problem of Double Zero aluminum foil:

The stickiness problem of Double Zero aluminum foil can be solved through a variety of measures aimed at improving the mechanical properties and surface properties of the aluminum foil. Here are some possible solutions:

1. Optimize the annealing process

The annealing process is adjusted to ensure the foil reaches the required softness without affecting its mechanical properties.

Fine-tune annealing temperature and duration to achieve the best balance between softness and strength.

2. Control rolling oil application

Monitor and control the amount of rolling oil used during the rolling process.

Ensure that the rolling oil used has the appropriate physical and chemical properties to promote proper lubrication without leaving excessive residue.

3. Improve oil removal effect

After annealing, the oil removal treatment is strengthened to eliminate residual oil on the surface of the foil.

Implement effective degreasing methods, such as using appropriate solvents or detergents, to achieve the desired level of cleanliness.

4.Surface treatment

Consider surface treating aluminum foil to enhance its anti-stick properties and reduce the likelihood of sticking.

Surface treatments can include coatings or modifications to the surface chemistry of the foil to improve its sliding properties.

5. Tension control during rewinding and slitting

Optimize the tension parameters during the winding and slitting process to prevent excessive inter-layer pressure.

Proper tension control helps minimize the risk of layers sticking together and improves the unwinding characteristics of the foil.

6. Quality monitoring and testing

Strict quality control measures are implemented to monitor the mechanical properties and surface properties of the aluminum foil.

Factors such as tensile strength, elongation and surface cleanliness are tested regularly to ensure the foil meets the required specifications.

Conclusion

All in all, Double Zero foil demonstrates the innovative and versatile nature of aluminum as a material. Its unique combination of ultra-thin construction, high purity, superior barrier properties and heat resistance make it an indispensable tool in a variety of industries.

From keeping food fresh to making electronic devices more efficient, Double Zero aluminum foil plays a vital role in shaping our modern world.

As technology advances and new applications emerge, the importance of Double Zero aluminum foil is likely to continue to grow, cementing its position as a cornerstone material in various sectors.