- What is Aluminum coil sheet a1050 h24?

- Aluminum coil sheet a1050 h24 specifications

- Aluminum coil sheet a1050 h24 material composition

- Aluminum coil sheet a1050 h24 strength and hardness

- Aluminum coil sheet a1050 h24 processing performance

- Aluminum coil sheet a1050 h24 corrosion resistance

- Aluminum coil sheet a1050 h24 application fields

- Aluminum coil sheet a1050 h24 surface treatment

What is Aluminum coil sheet a1050 h24?

A1050 is a grade of aluminum alloy, and H24 is a state name.

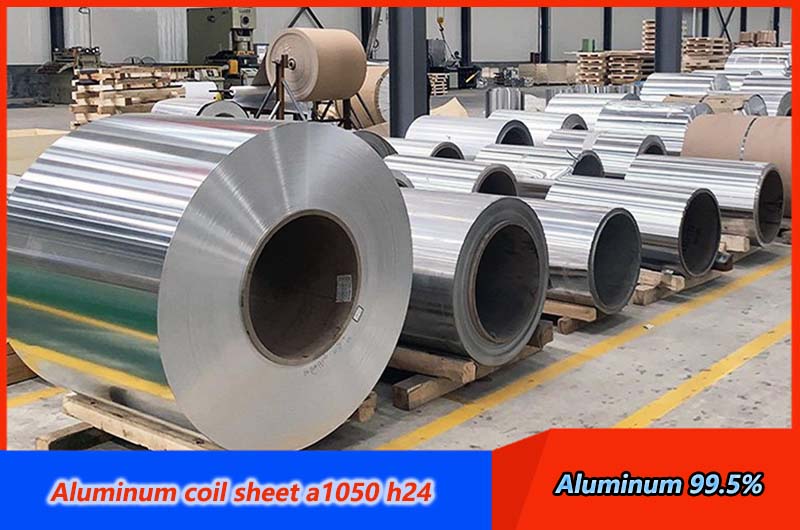

- A1050: This is a pure aluminum alloy with a minimum aluminum content of 99.5%. It is typically used for general sheet metal processing requiring moderate strength.

- H24: This temper designation indicates that the aluminum has undergone strain hardening and partial annealing. H24 indicates the product has been strain hardened and then partially annealed to a quarter-hard state.

H24 refers to work hardening after incomplete annealing, making the coil reach medium hardness. The process includes intermediate annealing and cold rolling.

The hardness of 1050 H24 aluminum coil is the same as that of 1050 H14 aluminum coil, but its elongation is better.

Aluminum coil sheet a1050 h24 specifications

The thickness of aluminum coil a1050 h24 is between 0.2mm and 8mm, which is suitable for complex punching, bending and stretching.

The width of h24 1050 aluminum coil plate ranges from 100mm to 1650mm.

Although it is called a roll sheet, the standard is based on the roll material standards in production. If necessary, the roll material can be further made into sheets.

Aluminum coil sheet a1050 h24 material composition

A1050 is a pure aluminum alloy with an aluminum content of not less than 99.5%. This makes it a versatile aluminum alloy material suitable for a variety of applications.

Aluminum coil sheet a1050 h24 strength and hardness

H24 is a quenched state, indicating that it has undergone strain hardening and partial annealing. This gives the aluminum coil plate a certain strength and hardness, making it suitable for some applications that require material strength.

Aluminum coil sheet a1050 h24 processing performance

A1050 H24 aluminum coil plate has good processing performance and can be shaped through rolling, stretching and bending. This property makes it ideal for manufacturing a variety of products.

Aluminum coil sheet a1050 h24 corrosion resistance

Aluminum has good corrosion resistance, and for some applications that require long-term exposure to harsh environments, such as outdoor building materials, A1050 H24 aluminum coil is a reliable choice.

Aluminum coil sheet a1050 h24 application fields

Due to its versatility and good performance, A1050 H24 aluminum coil is widely used in construction, electronics, transportation, home appliances and other fields. For example, it can be used to manufacture building exterior panels, aircraft shells, automobile parts, etc.

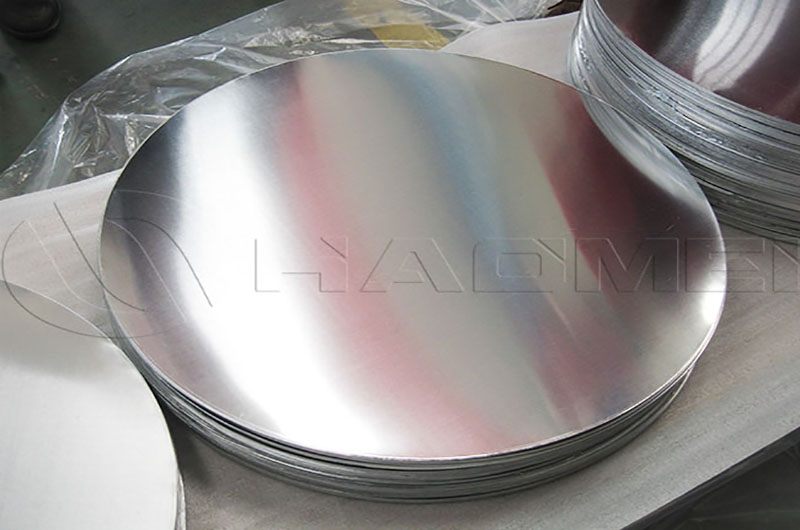

The medium hardness and good elongation make it an excellent material for CTP, PS plates, plastic-aluminum composite panels, lighting panels, battery explosion-proof materials, sign boards, insulation coil sheets, etc.

A1050-H24 aluminum coil is commonly used in lighting appliances, reflectors, decorations, chemical containers, heat sinks, labels, electronics, lamps, nameplates, electrical appliances, stamping parts and other products. In some situations where corrosion resistance and formability are required but strength is not high, chemical equipment is a typical use.

Aluminum coil sheet a1050 h24 surface treatment

Depending on the specific application requirements, A1050 H24 aluminum coil can undergo different types of surface treatments, such as anodizing, spraying, etc., to increase its surface hardness and improve its appearance.

Aluminum is a recyclable material, so A1050 H24 aluminum coil has good environmental performance. In the process of production and use, it can better meet the requirements of sustainable development.

Overall, A1050 H24 aluminum coil is a versatile material that combines good strength, processability, and corrosion resistance, making it suitable for a variety of different industrial applications.

The coil has the characteristics of high plasticity, corrosion resistance, and good electrical and thermal conductivity. As a member of pure industrial aluminum, it has low strength and cannot be strengthened through heat treatment. Its biggest advantage over other series is its simple process and low price.

Informations you may be interested in:

- 0.5mm thick 3003 anti-corrosion thermal insulation aluminum coil

- Aluminum Coil for Power Plant Insulation

- Stucco embossed aluminum coil for pipe insulation

- What precautions should be taken when applying thermal insulation aluminum coils?

- Characteristics and storage precautions of aluminum coils for thermal insulation

- What are the benefits of aluminum insulation?

- Is aluminum a good thermal insulator?