- Q: What is the main purpose of power plant insulation aluminum coils?

- Q: What are the characteristics of aluminum coils for insulation compared with other materials?

- Q: What are the specifications of power plant insulation aluminum coils?

- Q: What should I pay attention to when using thermal insulation aluminum coils?

- Q: What are the frequently asked questions about power plant insulation aluminum coils?

Q: What is the main purpose of power plant insulation aluminum coils?

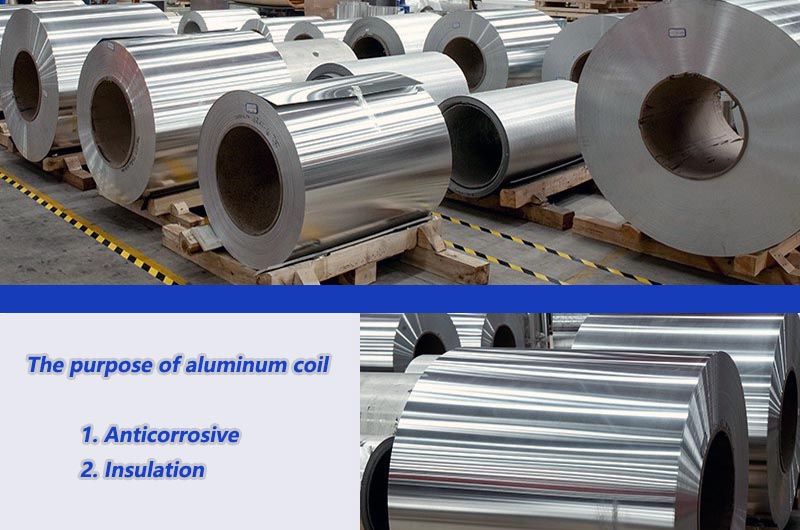

Power plant insulation aluminum coils are mainly used to wrap around the pipes of various power plants to play the role of anti-corrosion and thermal insulation. It plays the role of covering, protecting, anti-corrosion, waterproofing and thermal insulation on power plant equipment, pipes or containers, helping to reduce energy loss and improve the energy efficiency performance of equipment.

Q: What are the characteristics of aluminum coils for insulation compared with other materials?

Compared with other materials, aluminum coils for insulation have good flatness, corrosion resistance, decorative properties and mechanical properties. It can achieve tight coating on the pipe surface, has corrosion resistance, beautiful appearance, and has sufficient mechanical properties to adapt to the physical stress during installation and winding.

Aluminum coils for power plant insulation usually refer to one of the insulation materials used for power plant equipment, pipes or containers. Aluminum coils are mainly used for the outer covering of the insulation layer.

- Good thermal conductivity: Aluminum coil has good thermal conductivity, which helps to reduce heat loss and improve thermal insulation effect.

- Lightweight and corrosion-resistant: Aluminum coils are relatively lightweight and have good corrosion resistance, and can maintain stable performance in different environments.

- Ease of processing: Aluminum coils are easy to process into various shapes to adapt to the surfaces of different equipment and pipes.

- Aesthetics: The surface of aluminum coils is usually treated to have a certain aesthetics and help improve weather resistance.

- Waterproof: The outer covering of the aluminum coil helps to waterproof and avoid the impact of external moisture on the insulation material.

- Wear resistance: Aluminum coils can provide a certain degree of wear resistance and protect the insulation layer from external physical damage.

In power plant insulation systems, aluminum coils are usually used in combination with other insulation materials (such as rock wool, glass wool, etc.) to build an effective insulation layer to reduce energy loss and improve the energy efficiency of the equipment.

Q: What are the specifications of power plant insulation aluminum coils?

Aluminum coil material: The 1100, 1060, and 3003 aluminum coils you mentioned are all common aluminum alloy materials. They may be chosen in power station insulation applications because aluminum is lightweight, conducts electricity well, and resists corrosion.

- Coil specifications: The normal width of the thermal insulation aluminum sleeve coil is one meter, and the thickness depends on the mechanical needs. Common thicknesses include 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm and 1.0mm. The selection of these specifications may depend on specific engineering requirements and insulation performance needs.

- Aluminum coil status: You specified the status of the insulating aluminum coil as H24 (semi-rigid). Aluminum alloys in the H24 state are usually cold worked and naturally aged, and have a certain hardness and strength.

- Coiled material weight: You mentioned that the rolled material weight is 50kg, but some generally do not exceed 70kg for the convenience of construction. This may be to ensure ease of installation and handling. Lightweight roll materials may be easier to handle and install.

In general, the selection of power station insulation materials depends on specific engineering needs, including insulation performance, corrosion resistance, mechanical properties, and ease of construction and maintenance. If you have specific questions or need more detailed information, please feel free to ask.

Q: What should I pay attention to when using thermal insulation aluminum coils?

In the water-cooling wall of the power plant, the insulation aluminum coils are replaced every three years or so. The thickness of thermal insulation aluminum coils varies according to different regions and needs. High-temperature places generally use 0.5mm thick thermal insulation aluminum coils, while places with lower temperatures may choose thicker aluminum coils to provide better insulation effects. Factors such as environmental conditions, temperature requirements, and budget need to be considered when selecting to ensure that the insulation needs of the specific application scenario are met.

When selecting aluminum coils, parameters such as thickness, width, and length need to be considered to ensure that they are suitable for specific application scenarios. In addition, appropriate insulation materials and covering methods need to be selected according to the climatic conditions and process requirements of different regions.

Q: What are the frequently asked questions about power plant insulation aluminum coils?

Some common problems may be encountered in the insulation aluminum coils used in power plants. Here are some possible problems and possible solutions:

- 1. Corrosion problem: Aluminum coils may be corroded after being exposed to harsh environments for a long time. This may affect its appearance and performance. Solutions include regular cleaning and the application of anti-corrosion coatings.

- 2. Installation problems: Incorrect installation may cause damage or poor sealing of the insulation aluminum coil. Make sure to strictly follow the manufacturer's guidelines during installation and ensure that appropriate fixing and sealing materials are used.

- 3. Temperature fluctuations: Power plant equipment may experience large temperature changes. This can cause the aluminum coil to expand and contract, affecting its performance. Choose an aluminum alloy with good thermal expansion properties and make sure that temperature changes are taken into account during installation.

- 4. Mechanical damage: In a power plant environment, thermal insulation aluminum coils are susceptible to mechanical damage, such as impact or extrusion. Use a wear-resistant, high-strength aluminum alloy with extra protection in areas that may be subject to physical damage.

- 5. Insulation performance: The insulation performance of aluminum coils is crucial to the safe operation of power plant equipment. Check the insulation performance regularly to ensure it will meet requirements during its service life.

- 6. Fire safety: The power plant is a potential fire risk area, so the insulation material should have good flame retardant properties. Make sure to choose aluminum coils that meet relevant safety standards.

- 7. Cost issue: Sometimes, cost is also a consideration. Ensure that performance needs are met while also considering the cost-effectiveness of materials.

Regular maintenance and inspections are key to ensuring the long-term reliable performance of power plant insulation aluminum coils. When faced with any problem, it is best to contact the manufacturer or professional engineers for accurate advice and solutions.

Informations you may be interested in:

- 0.5mm thick 3003 anti-corrosion thermal insulation aluminum coil

- Stucco embossed aluminum coil for pipe insulation

- What precautions should be taken when applying thermal insulation aluminum coils?

- Characteristics and storage precautions of aluminum coils for thermal insulation

- What are the benefits of aluminum insulation?

- Is aluminum a good thermal insulator?

- 1050 thermal insulation aluminum coil