- Why choose aluminum circle 1050 for making cooking ware?

- Aluminum circle 1050 for making cooking ware specifications

- Aluminum circle 1050 for making cooking ware applications

Why choose aluminum circle 1050 for making cooking ware?

The choice of Aluminum Circle 1050 for the manufacture of cookware was not random but stemmed from its superior properties, carefully designed to meet the needs of cooking enthusiasts across the globe.

1. Excellent thermal conductivity

Aluminum Circle 1050 has excellent thermal conductivity, ranking among the best of all metals used in cookware production. This feature helps distribute heat quickly and evenly across the entire cooking surface, ensuring consistent cooking results and preventing hot spots. Whether simmering delicate sauces or searing juicy meats, the Aluminum Circle 1050 guarantees precise temperature control, allowing chefs to unleash their culinary creativity without limits.

2. Lightweight yet strong

In the pursuit of culinary excellence, the weight of your cookware can impact or enhance the cooking experience. The Aluminum Circle 1050 strikes the perfect balance between lightweight maneuverability and structural integrity. Its feather-light composition makes handling easy and reduces fatigue during long cooking sessions. Despite its lightweight appearance, Aluminum Circle 1050 exhibits exceptional resistance to dents and warping, allowing it to withstand the rigors of daily use in professional kitchens and home environments alike.

3. Corrosion resistance

The corrosive nature of certain cooking ingredients and cleaning agents poses a permanent challenge to the service life of your cookware. However, Aluminum Circle 1050 rises to the occasion with its inherent corrosion resistance. Aluminum Circle 1050 is anodized or coated with a non-stick surface for enhanced durability and longevity, ensuring long-lasting performance throughout its lifetime. Say goodbye to unsightly stains and unpleasant metallic tastes, because Aluminum Circle 1050 remains resistant to corrosion, preserving the purity of your culinary creations.

4. Beautiful

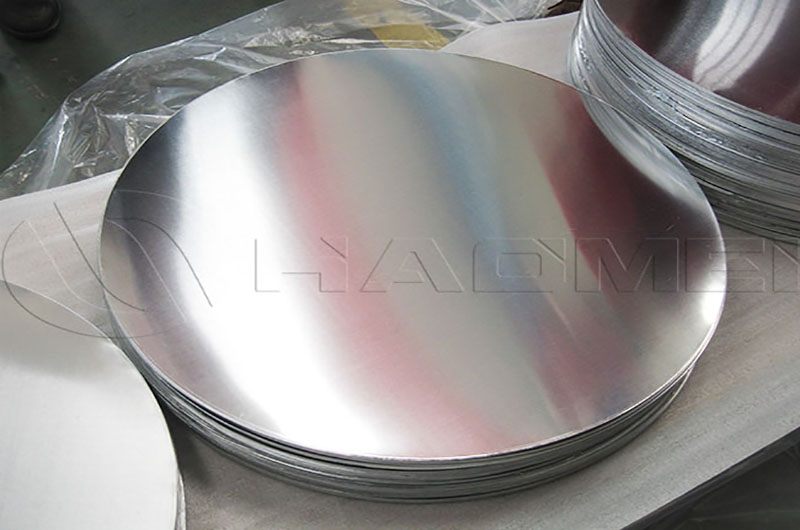

In addition to its functional attributes, Aluminum Circle 1050 adds a sophisticated touch to the kitchen landscape. Its smooth, glossy surface exudes timeless elegance and enhances the visual appeal of any cooking combination. Whether decorating countertops or gleaming on the stovetop, Aluminum Circle 1050 transforms mundane cooking tasks into an aesthetic delight, taking the cooking experience to new heights.

Aluminum circle 1050 for making cooking ware specifications

1. Composition

Aluminum Circle 1050 is the epitome of purity, containing 99.5% aluminum and trace amounts of other elements.

2. Thickness

The thickness of aluminum round 1050 varies depending on the intended use, ranging from 0.5 mm to 4 mm. Thinner discs are better suited for lightweight utensils like frying pans and woks, while thicker discs are suitable for sturdy cookware like stockpots and Dutch ovens.

3. Diameter

Aluminum Circle 1050 is available in a variety of diameters to suit different cookware sizes and designs. From small saucepans to large frying pans, the diameter of the Aluminum Round 1050 can be customized to meet specific cooking needs, ensuring optimal performance and efficiency.

4. Surface treatment

Finish options for Aluminum Circle 1050 include a range of finishes, each offering unique advantages in functionality and aesthetics. Anodizing enhances corrosion resistance and promotes adhesion of the nonstick coating, while polished or brushed finishes give cookware a luxurious shine.

Aluminum circle 1050 for making cooking ware applications

- Pots and Pans: Aluminum circle 1050 is frequently used for manufacturing pots and pans of various sizes and shapes. These may include saucepans, stockpots, frying pans, and sauté pans. The excellent heat conductivity of aluminum ensures even cooking and efficient heat distribution, making it ideal for such cookware.

- Cooking Utensils: Aluminum circle 1050 can also be used to make cooking utensils such as ladles, spoons, spatulas, and whisk handles. Its lightweight nature makes these utensils easy to handle during cooking.

- Bakeware: While aluminum circle 1050 is more commonly associated with stovetop cookware, it can also be used to make certain types of bakeware such as baking sheets, cake pans, and muffin tins. Its heat conductivity allows for even baking, while its corrosion resistance ensures durability.

- Pressure Cookers: Aluminum circle 1050 may be used in the construction of pressure cookers, which rely on efficient heat transfer and durability to withstand high temperatures and pressure.

- Steamers and Strainers: Aluminum circle 1050 can be formed into steamers and strainers used for steaming vegetables or draining pasta. Its corrosion resistance makes it suitable for contact with boiling water.

- Griddles and Grill Pans: Aluminum circle 1050 can be used to manufacture griddles and grill pans, providing a non-stick surface and even heat distribution for cooking meats, vegetables, and other foods.

Aluminum circle 1050 has a wide range of uses and is commonly used in various types of cookware due to its excellent thermal conductivity, lightness, corrosion resistance and formability. However, it's worth noting that aluminum cookware may not be suitable for all cooking methods, especially those involving acidic ingredients, as aluminum can react with acidic foods.

Informations you may be interested in:

- 1060 Aluminum Circle Discs Blanks for Pot

- 1060 Aluminum Circle Discs for Cookware

- 2.4mm deep drawn 3003 aluminum disc for electric pressure cooker

- Pizza Trays 3003 Aluminum Disc

- Food grade 3003 aluminum disc: Electric frying pan 3003 aluminum disc

- Round 3003 Aluminum Discs Deep Spining Punching Aluminum Barrel Materials

- 3003 aluminum circle for non stick pan

- Polished DC 3003 Aluminum Circles for Baking Tray

- Aluminium circle for making pot 1060 3003

- 3003 Aluminum Circle for Cookware