- Diamond Plate Sheet Specifications

- 4x8 Aluminum Diamond Plate

- Aluminum Diamond Plate for Sale

- Best Way to Cut Aluminum Diamond Plate Sheets

- How to Polish Aluminum Diamond Plate Sheets

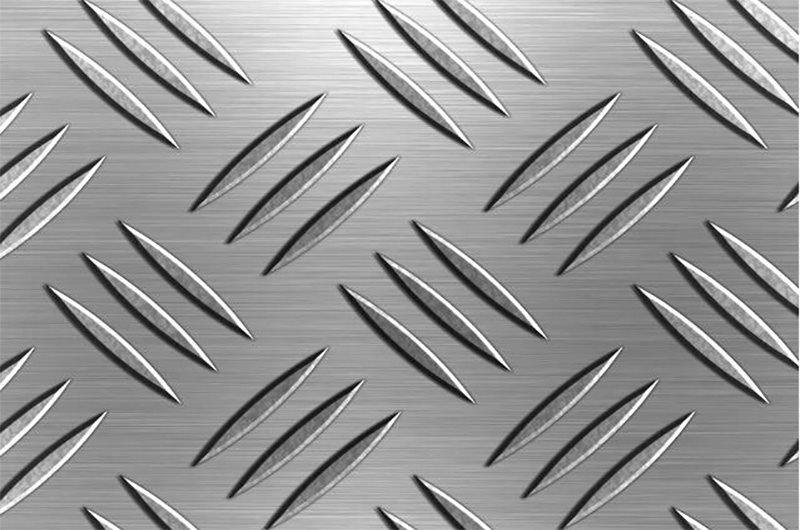

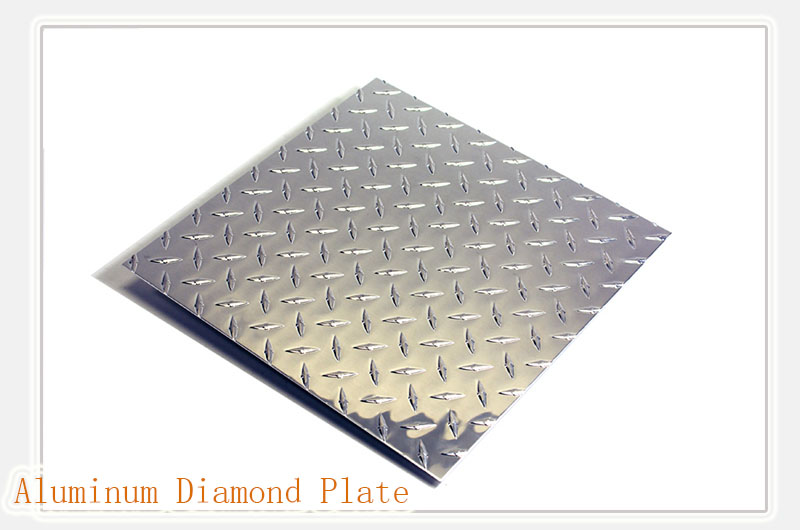

Aluminum diamond plate, also known as aluminum tread plate, is an aluminum plate with a raised diamond pattern on one side. The diamond pattern is embossed and raised through the surface of the aluminum plate, providing a non-slip surface that is both durable and easy to clean.

The diamond pattern is commonly used in flooring, wall panels, tool boxes and other applications requiring a non-slip, durable and decorative appearance. It is also lightweight, corrosion resistant and easy to form, making it a popular choice in many industries.

Aluminum diamond plates are available in a variety of thicknesses, widths and lengths, and can be custom cut to suit specific applications. It installs easily using screws, rivets or adhesives, and can be painted or anodized for extra protection against corrosion and wear.

In conclusion, Aluminum Diamond Sheet is a versatile and durable material that is popular in a wide range of applications due to its non-slip surface, durability and ease of installation.

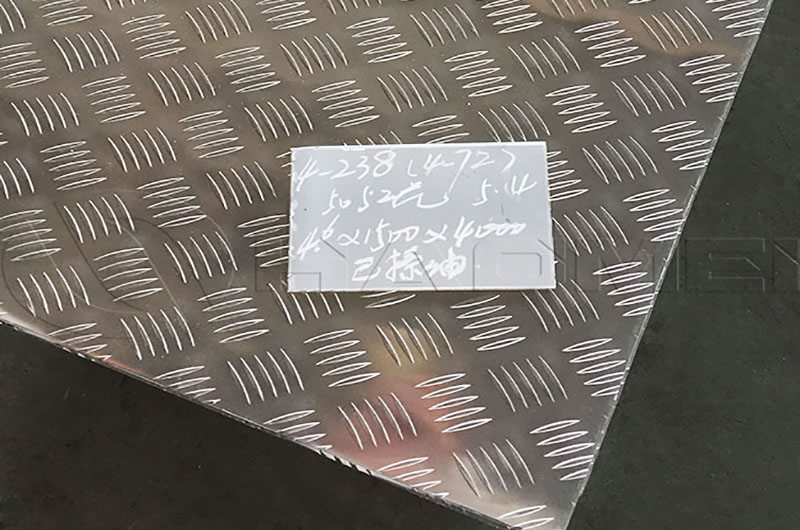

Diamond Plate Sheet Specifications

Typical Sizes

Common dimensions for aluminum diamond plates include :

However, custom sizes are also available to suit specific applications.

1/4 Aluminum Diamond Plate

1 4 inch diamond plate aluminum is more durable and suitable for heavy duty applications.

- Heavy-duty truck and trailer floors, loading ramps and walkways

- Industrial applications such as mechanical equipment protection

- High traffic areas requiring extra durability and impact resistance

1/8 Aluminum Diamond Plate

1 8 inch diamond plate aluminum for any application with thinner, lighter materials.

- Wall panels, siding and backsplashes in commercial and residential environments

- Light Truck and Trailer Flooring

- Interior applications such as stair treads and decorative finishes

3/16 Aluminum Diamond Plate

3 16 aluminum diamond plates are suitable for any application requiring a balance between durability and weight

- Tool boxes, tanks and other small equipment enclosures

- Indoor and outdoor stair treads

- Boat decks and piers

Alloy

Diamond plate sheets are usually made of aluminum alloy 3003, which is a medium strength alloy with good corrosion resistance and machinability. Depending on the application, other alloys such as 5052 and 6061 can also be used.

Product Standards

Product standards for aluminum diamond plates vary depending on the manufacturer and the intended use of the product.

- ASTM B209 for General Purpose Aluminum Sheet and Plate

- ASTM F1267 for non-slip floors

- MIL-DTL-46027 for armor plates

Surface Treatment

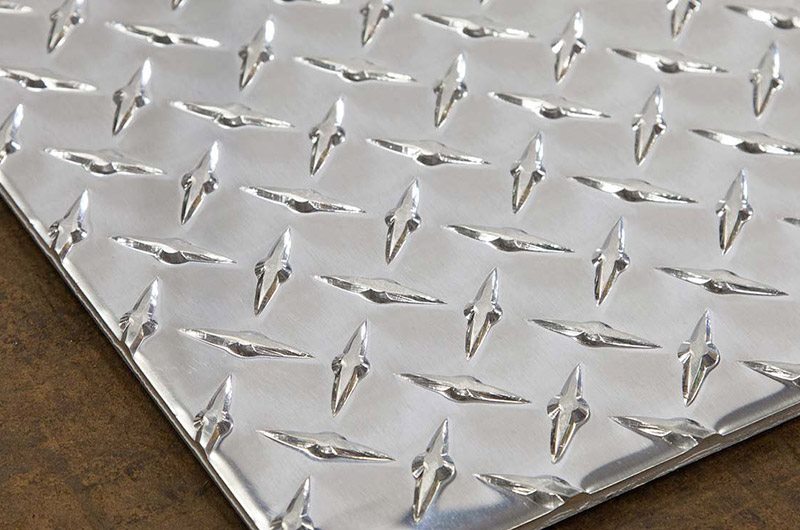

Surface treatments for aluminum diamond plates can include ground (unfinished), polished or anodized.

Polishing is the standard finish and is suitable for most applications.

Polishing and anodizing provide additional corrosion and wear protection and also enhance the appearance of the diamond plate.

The surface preparation required for Aluminum Diamond Plate depends on the intended use and desired finish.

- If a polished or reflective finish is desired, the board may need to be buffed and buffed.

- If a colored finish is desired, the sheet may need to be painted or anodized.

- For applications where corrosion resistance is important, a protective coating or anodizing may be required.

Certifications

Certifications for aluminum diamond plates can include compliance with various industry standards, Quality Management System ISO 9001, Environmental Management System ISO 14001 and Occupational Health and Safety Management System OHSAS 18001.

Aluminum Diamond Plate Thickness Chart

| Thickness (inches) | Thickness (mm) | Typical Applications |

|---|---|---|

| 0.025 | 0.6 | Decorative purposes, protective layer |

| 0.045 | 1.1 | Trailer floors, walkways |

| 1/16 | 1.6 | Truck flooring, toolboxes, decorative trim |

| 1/8 | 3.2 | Heavy-duty flooring, stairs, catwalks |

| 3/16 | 4.8 | Loading ramps, dock plates |

| 1/4 | 6.35 | Industrial flooring, structural applications, high-stress environments |

4x8 Aluminum Diamond Plate

Aluminum Diamond Plate Sheets 4x8

Aluminum Diamond Plate Sheets 4x8 refers to diamond-shaped aluminum sheets measuring 4 feet by 8 feet. Due to its durability, slip resistance and aesthetics, 4x8 aluminum diamond plate is commonly used in floors, walls and trailers.

0.25 Aluminum Diamond Plate 4x8 Sheet

0.25 Aluminum Diamond Plate 4x8 Sheet This specification refers to a diamond-shaped aluminum sheet that is 0.25 inches (6.35 mm) thick and measures 4 feet by 8 feet. 0.25 Aluminum Diamond Plate is a thicker, heavier option for industrial and commercial applications such as loading docks, stair treads, and tool boxes.

48 x 96 Aluminum Diamond Plate

48 x 96 Aaluminum Diamond Plate and 48" x 96" Diamond Aluminum Plate : These specifications refer to the Diamond Diamond Plate measuring 48" x 96" (or 4' x 8'). They are equivalent to the first specification mentioned above.

Black Diamond Plate Sheets

1/8 Black Aluminum Diamond Plate is a 1/8 inch (3.2 mm) thick black diamond shaped aluminum plate.

Black Diamond Plate Sheets 4x8 are black diamond shaped aluminum sheets measuring 4ft x 8ft.

1/8 Black Aluminum Diamond Plate and Black Diamond Plate Sheets 4x8 are often used for decorative purposes such as vehicle trim, garage walls, and countertops.

Aluminum Diamond Plate for Sale

Aluminum Black Diamond Plate

Aluminum black diamond plate, also known as black aluminum tread plate or black aluminum checker plate, is an aluminum diamond plate with black finish. It is commonly used for decorative purposes in the automotive, architectural and interior design industries.

Commonly used alloys for Black Aluminum Diamond Plate are 3003 and 6061 aluminum alloys, which are known for their high strength, corrosion resistance and good weldability.

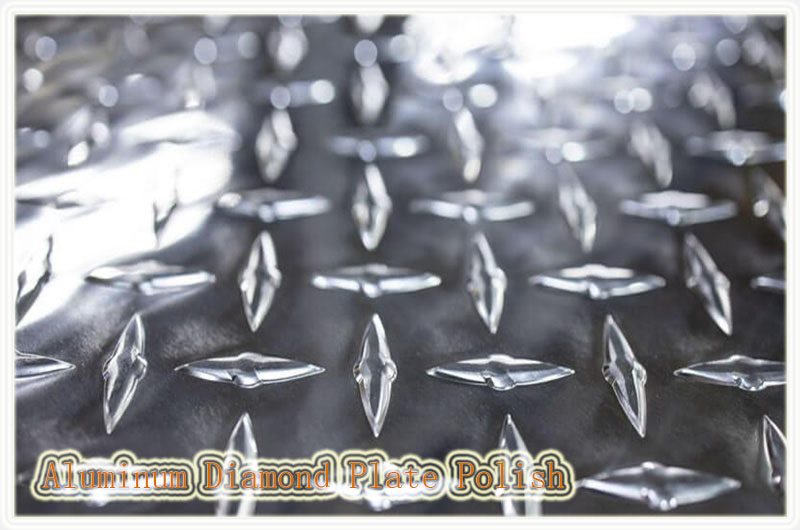

Aluminum Diamond Plate Polish

Aluminum Diamond Plate Polish is a surface treatment that involves the surface of Aluminum Diamond Plate Polish to make it smooth and shiny. It is commonly used in the construction, decoration and automotive industries to enhance the appearance of diamond aluminum sheets and provide a reflective surface.

The alloys commonly used in Aluminum Diamond Plate Polish are 3003 and 6061 aluminum alloys, which are famous for their high strength, corrosion resistance and good polishing performance.

Typically, aluminum diamond plates for black finish or polish require surface treatment to prepare the surface for coating or polishing. This may involve cleaning, degreasing and sanding the surface to remove any dirt, oil or corrosion. Surface preparation may also include the application of a protective coating or varnish to enhance durability and protect the surface from damage.

Best Way to Cut Aluminum Diamond Plate Sheets

There are a variety of tools that can be used to cut aluminum diamond sheets, depending on the thickness of the material and the intended use. Here are some of the best ways to cut aluminum diamond slabs :

- Circular Saws with Carbide Blades : Circular saws with carbide blades are an excellent choice for cutting aluminum diamond plates up to 1/4" (6.35mm) thick. The blade's carbide teeth cut through aluminum without dulling quickly.

- Jigsaw with metal cutting blades : Jigsaws with metal cutting blades are another good option for cutting aluminum diamond sheets. This method is best for cutting curves or complex shapes in thinner sheets up to 1/8 inch (3.2 mm) thick.

- Table Saws with Carbide Blades : Table saws with carbide blades are suitable for cutting thicker aluminum diamond plates up to 1/2 inch (12.7 mm) thick. This method produces a clean, straight cut, but may require more effort.

- Plasma Cutter : A plasma cutter is a powerful tool that can easily cut thick aluminum diamond slabs. This method produces precise cuts and can be used for both straight cuts and curved shapes.

- Waterjet cutting machine : Waterjet cutting machine is another high-precision method of cutting aluminum diamond sheet. This method uses a high-pressure water jet mixed with abrasive particles to cut the material cleanly and accurately.

No matter which method you choose, it is important to wear protective gear such as goggles and gloves and take proper safety precautions when cutting aluminum diamond plates.

How to Polish Aluminum Diamond Plate Sheets

Polishing aluminum diamond sheets can give them a shiny and reflective finish, ideal for decorative and aesthetic applications. Following are the steps to polish an aluminum diamond plate :

- Cleaning the surface : Before polishing, it is important to thoroughly clean the surface of the aluminum diamond plate to remove any dirt, debris or oil. You can use a solution of warm water and a mild detergent, then rinse with clean water.

- Grinding the surface : Next, use a sanding block with 400-grit sandpaper or an orbital sander to abrade the surface of the aluminum diamond plate in a circular motion. This will help remove any scratches or blemishes on the surface and prepare it for polishing.

- Apply polish : Apply a small amount of polish to the surface of the aluminum diamond plate. You can use a polishing cloth or buffer to spread the compound evenly over the surface.

- Grinding the surface : use a polishing cloth or buffer solution to polish the surface of the aluminum diamond plate in circles. Be sure to apply even pressure, working in small portions at a time.

- Cleaning the surface : After polishing the entire surface of the aluminum diamond plate, clean it with a soft cloth to remove any remaining polish or debris.

- Apply a protective coating : Finally, to help preserve the finish, you can apply a protective coating or varnish to the surface of the aluminum diamond plate. This will help prevent scratches and keep the finish looking like new.

By following these steps, you can achieve a smooth, shiny finish on aluminum diamond slabs.

Informations you may be interested in: