- Aluminum Checker Plate for Sale

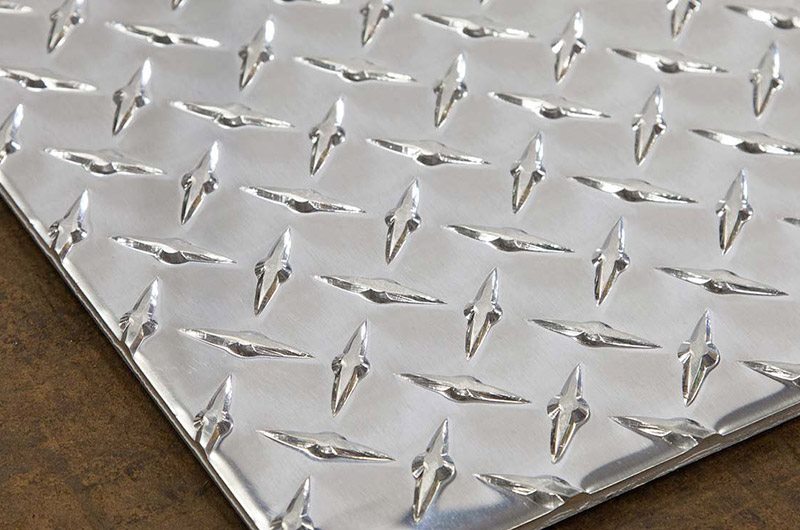

- Typical Aluminum Checker Plate

- Common Uses of Aluminum Checker Plate

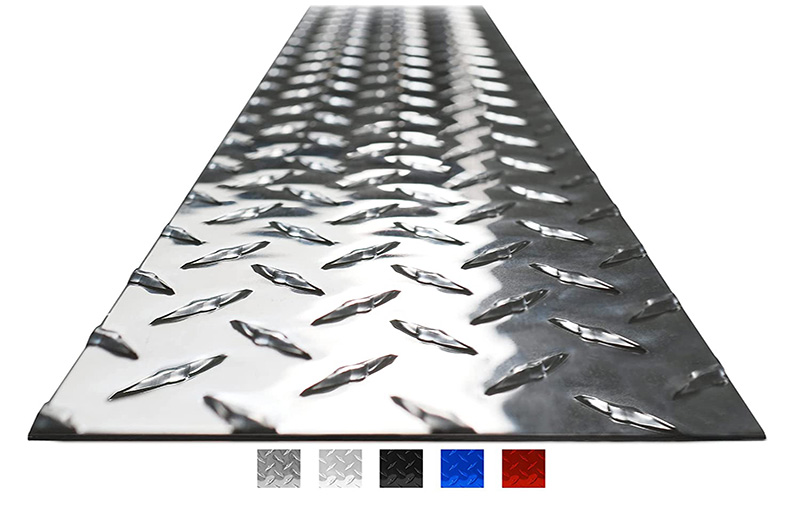

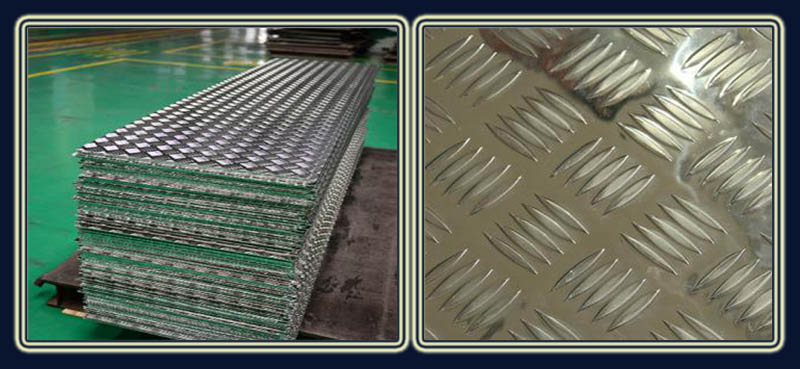

Aluminum checker plate, also known as aluminum tread plate or aluminum diamond plate, is a light-weight metal plate with diamond-shaped or strip-shaped raised patterns on one side. It is made of aluminum alloy and is commonly used in various applications due to its durability, corrosion resistance and aesthetics.

The raised pattern on the surface of the aluminum checker plate provides additional traction and reduces the risk of slipping, making it suitable for applications where slip resistance is important.

Aluminum Checker Plate for Sale

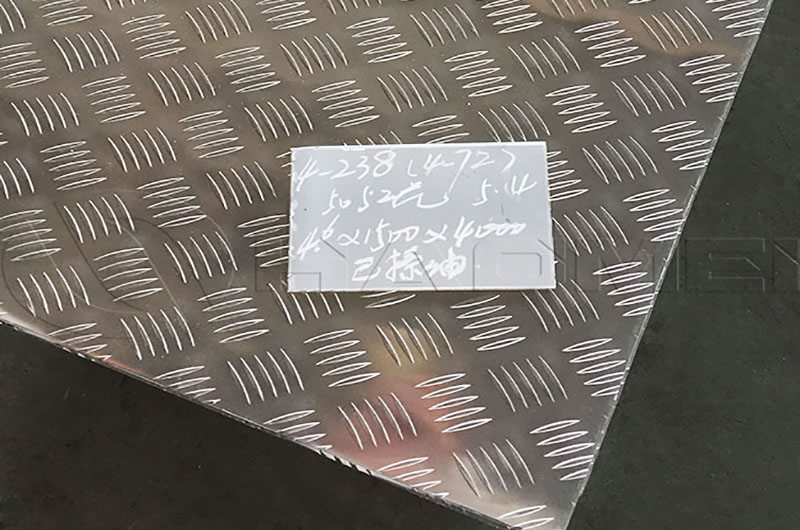

Aluminum checker plate specifications may vary by application and manufacturer. However, here are some common specifications and details related to aluminum checkered plates :

- Alloy : 3003/6061.

- Pattern : Diamond/1 bar/2 bar/3 bar/5 bar. A diamond pattern consists of raised diamonds, while a bar pattern consists of raised bars.

- Length, Width and Thickness range : Aluminum checkered plates may vary in length and width, but are usually available in standard plate sizes such as Thicknesses typically range from 1.5mm to 6mm, but thinner or thicker sheets are available on request.

- Rib Height : The height of the raised surface of the chessboard is called the rib height. Rib height may vary depending on the specific product, but is usually between 1.0mm and 2.5mm.

- Color : natural metallic silver, black aluminum checker plate, white aluminum checker plate. However, some manufacturers offer paint or coating options in different colors for specific applications.

-

Surface Treatment : Aluminum grating may be given a variety of surface treatments to enhance its performance or appearance. Common surface treatments include

- Polished (natural untreated surface)

- Anodizing (electrochemical treatment to increase corrosion resistance and provide color options)

- Powder Coated (Durable Colored Powder Coat Applied)

- Common Size : 4x8ft (1220x2440mm) and 4x10ft (1220x3050mm) panels.

However, different sizes are available upon specific request and can be cut to custom sizes.

Thinner tread plates (e.g. 1.5mm to 3mm) are typically used in applications where weight reduction is a priority while still providing some slip resistance. For applications requiring greater strength and load-bearing capacity, choose thicker gratings (e.g. 4mm to 6mm).

It is worth noting that specific product specifications and availability may vary by manufacturer and supplier. Therefore, it is advisable to consult the supplier or manufacturer for accurate information on aluminum checkered plate dimensions, alloys, patterns and finishes.

Typical Aluminum Checker Plate

2mm Aluminum Checker Plate

2mm aluminum checker plates are commonly used for indoor and outdoor applications where a lightweight and durable material is required. This thickness is suitable for projects such as wall cladding, decorative uses, small ramps or steps, and light flooring.

- Common alloy : The common alloy used for 2mm aluminum checker plate is usually 3003.

- Alloy temper : The alloy temper can vary, but the most common temper is H22, which indicates the strain hardened and partially annealed temper.

3mm Aluminum Checker Plate

- Common Applications : 3mm aluminum checker plates are often used in applications where a balance between strength and weight is required. They are suitable for a variety of flooring applications such as industrial floors, vehicle floors, stair treads and high traffic areas.

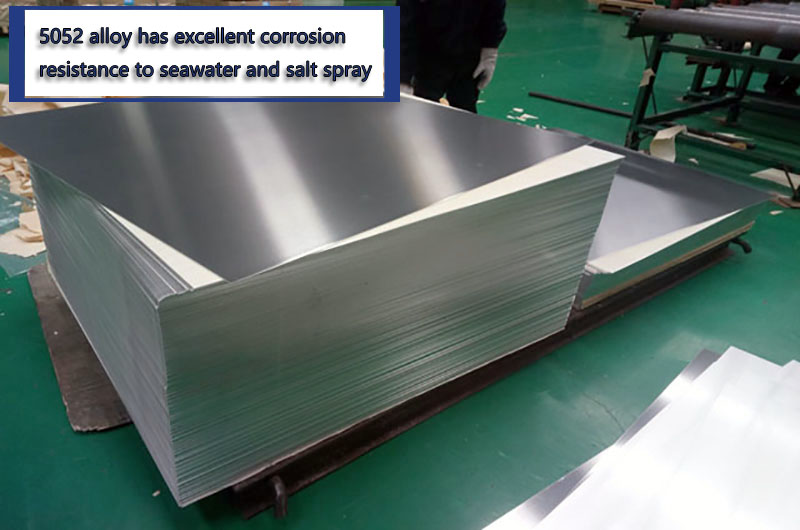

- Common alloy : The common alloy used for 3mm aluminum checker plate is usually 5052.

- Alloy State : The alloy state can vary, but H114 and H22 are commonly used. H114 indicates the strain hardened and tempered condition, while H22 indicates the strain hardened and partially annealed condition.

Aluminum Checker Plate 4x8

- COMMON APPLICATIONS : Aluminum checkered panels measuring 4x8ft (1220x2440mm) are commonly used in applications such as flooring, wall cladding, trailer beds, tool boxes and various decorative uses. Larger sizes allow for wider coverage and easier installation.

- Common Alloys : Common alloys for 4x8 aluminum grating can include 3003, 5052 and 6061, depending on specific requirements and desired properties.

- Alloy Tempering : Alloying tempers will vary depending on the specific alloy chosen, common tempers include H22 and H114.

Black Aluminum Checker Plate

- Common Applications : Black patterned aluminum panels are often chosen for their aesthetics and are used in a variety of decorative and architectural applications. They can be used in wall panels, signs, interior design elements and automotive trim.

- Common alloys : Common alloys used for black pattern aluminum sheets include 3003 and 5052, etc.

- Alloy Tempering : Alloying tempers will vary depending on the specific alloy chosen, but commonly used tempers include H22 and H114.

White Aluminum Checker Plate

- Common Applications : White aluminum checkered panels are also used for decorative and architectural purposes, especially in environments where a clean and bright appearance is desired. They find applications in wall cladding, ceilings and interior design elements.

- Common Alloys : Common alloys used for white patterned aluminum sheets include 3003 and 5052, etc.

- Alloy Tempering : Alloying tempers will vary depending on the specific alloy chosen, but commonly used tempers include H22 and H114.

Self Adhesive Aluminum Checker Plate

- Common Applications : Self-adhesive aluminum grating is suitable for applications that require easy installation and temporary or semi-permanent bonding. They can be used for signage, temporary floors, shelters, and DIY projects.

- Common Alloys : Common alloys used for self-adhesive aluminum grating may vary by manufacturer and specific requirements.

- Alloy Tempering : Alloying tempers will vary depending on the specific alloy chosen, but commonly used tempers include H22 and H114.

Common Uses of Aluminum Checker Plate

Aluminum Checker Plate for Flooring

It is commonly used for flooring in industrial environments, walkways, ramps, stair treads and platforms where slip resistance and durability are critical.

- Alloy : 3003 aluminum alloy is commonly used in flooring applications due to its excellent corrosion resistance and formability.

- Alloy Tempering : Usually the H22 or H114 tempers are used, denoting the strain hardened and partially annealed tempers.

- Surface Treatment : The surface of the checkered panels can be satin finished or additionally treated such as anodizing or powder coating for enhanced durability and aesthetics.

Aluminum Checker Plate for Truck Bed Liners

Aluminum checker plates are often used as protective liners for truck beds, providing a durable and non-slip surface for cargo.

- Alloy : 5052 aluminum alloy is often the first choice for truck bed liners due to its high strength and corrosion resistance.

- Alloy state : The commonly used H114 state represents the strain hardened and tempered state.

- Surface treatment : Checkered panel surfaces may be satin finished, or they may be given a protective coating such as spray-coated bed liners or paint.

Decorative Application

Due to its attractive patterns and metallic appearance, patterned aluminum panels are also used in architectural and decorative applications such as wall cladding, signage and interior design.

- Alloys : Alloy selection for decorative applications may vary depending on specific design requirements and preferences. Common options include 3003 and 5052 alloys.

- Alloy state : commonly used H22 or H114 state.

- Surface Treatment : Decorative applications may involve various surface treatments such as anodizing, powder coating or painting to achieve the desired colour, finish and decorative effect.

Tool Boxes and Lockers

Because of its light weight and corrosion resistance, it is often used in the construction of tool boxes, storage cabinets, and utility boxes.

- Alloy : Aluminum alloys such as 5052 or 6061 are commonly used in tool boxes and lockers for their strength and durability.

- Alloy state : commonly used H22 or H114 state.

- Finishes : Checkered panels can be finished with a satin finish or with a protective coating such as powder coating or paint for enhanced durability and appearance.

Trailers and RVs

Aluminum checker plates are used for trailer floors, fenders and walls to enhance durability and reduce weight.

- Alloys : Aluminum alloys such as 5052 and 6061 are commonly used in trailers and RVs due to their strength and light weight.

- Alloy state : commonly used H22 or H114 state.

- Surface Treatment : The grating surface can be satin finished or given a protective coating such as anodizing or paint to withstand the outdoors and enhance durability.

Specific specifications and finishes may vary by manufacturer, supplier and specific project requirements. It is recommended that the manufacturer, supplier, or industry professional be consulted for accurate information and recommendations regarding the specific aluminum checkered plate used in the above applications.

Aluminum gratings are available in various thicknesses, sizes and alloys to meet different requirements. The pattern and height of the raised protrusions can also vary. The material can be easily cut, bent and welded, allowing for customization and easy installation.

Always follow safety precautions when working with aluminum checkered plates, such as wearing protective gloves and eye protection, as the edges can be sharp. In addition, regular cleaning and maintenance are recommended to maintain its appearance and prevent the accumulation of dust and dirt.

Please note that while I endeavor to provide accurate and up-to-date information, it is always best to consult the manufacturer or an industry professional for specific product details or recommendations.

Informations you may be interested in: