- Continuous anodized aluminum sheet coil specifications

- Continuous anodized aluminum sheet coil performance

- Advantages of Continuous anodized aluminum sheet coil as building materials

- Continuous anodized aluminum sheet coil applications

Anodizing aluminum is an electrolytic oxidation chemical process that forms an oxide film on its surface. Compared with the traditional process, the oxide film produced by this technology is as hard as diamond, will never fall off, and has a crystal clear high-end decorative effect.

Anodizing technology overcomes the shortcomings of traditional aluminum alloy surface treatment technology in terms of hardness, wear resistance, etc., expands the application range of aluminum alloys, and greatly extends the service life of aluminum alloys. It is currently the most widely used and most widely used technology in the world. Successful technology.

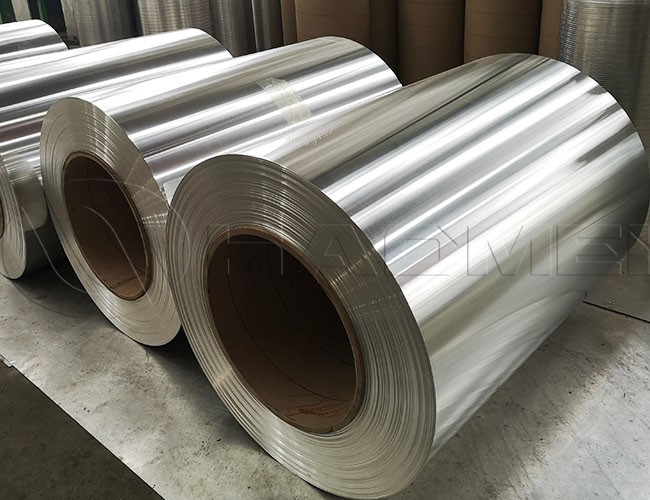

The continuous production technology is to continuously anodize the entire aluminum coil without cutting it. The innovation of this technology is a technological revolution in the new era, and it overcomes the technical defects of color difference and uneven film layer that occur in traditional flake oxidation.

The continuous oxidation production process results in no visual color difference in appearance, thereby achieving a bright decorative effect. The uniform thickness of the film ensures long-lasting and consistent product life and color.

Continuous anodized aluminum sheet coil specifications

| Attributes | value |

|---|---|

| thickness | 0.5~3.0mm |

| alloy | AA1100, AA3003, AA5052, AA5005 H32 |

| anodized film thickness | 5um, 12um, 15um, 20um(customizable) |

| width | 1220mm, 1500mm(customizable) |

| length | customizable |

Continuous anodized aluminum sheet coil performance

| Alloy | AA1100 | AA3003 | AA5052 | AA5005 |

|---|---|---|---|---|

| Tensile Strength (MPa) | 105 | 145 | 275 | 190 |

| Yield Strength (MPa) | 75 | 125 | 195 | 160 |

| Elongation (%) | 23 | 17 | 12 | 7 |

Advantages of Continuous anodized aluminum sheet coil as building materials

1. Easy to process: Anodized aluminum coils have very high processability and can adapt to various design needs of building appearance and interior decoration. Anodized aluminum coils not only have very good processability, but also have the ability to be processed in a short time. The ability to withstand continuous, high-intensity stamping gives it great advantages in decoration and can reduce product production costs and production cycles.

2. Very good weather resistance: Not only does it have a wide range of colors, but it can also ensure that it will not discolor, fade, oxidize, rust, corrode, scratch, etc. after long-term use, which makes it unique. It has a very high upper limit of use, service life and scope of application, and can be applied in more scenarios.

3. Easy to clean: We all know that there are many decorative materials. After being used for a period of time, dirt, stains, dust accumulation, damage, weathering, etc. will appear. However, anodized aluminum coils are different. Not only will they not The above situation occurs, and the dust accumulation rate is low, easy and simple to clean, and the maintenance and upkeep costs are quite low.

Continuous anodized aluminum sheet coil applications

Anodized aluminum plates are widely used in building exteriors, interior decorations, mechanical parts, aircraft and automotive parts, precision instruments and radio equipment, machine casings, lamp lighting, consumer electronics, handicrafts, household appliances, interior decoration, signs, furniture, automobile decoration and other industries. .

Especially in recent years, more and more buildings, spaces, and environments are more inclined to choose anodized aluminum coils when they need to be constructed, renovated, or decorated. Consumers and users' love for it has led to the use of Anodized aluminum coil decoration has become a trend, and has even become a manifestation of a trend.

Especially in public spaces and places such as subways, stations, exhibition halls, shopping malls, and airports, people like to use anodized aluminum sheets as decoration. Not only does it have good effects, but it can also show different effects according to different designs and colors. The effect brings different colors to buildings and indoor spaces, increasing the commercial value, ornamental value and tourist value of the area. It is an excellent modern building decoration material.

The widespread use of anodized aluminum sheet rolls in public spaces not only enhances the appearance of buildings, but also injects unique design elements into these places. The following are specific application examples:

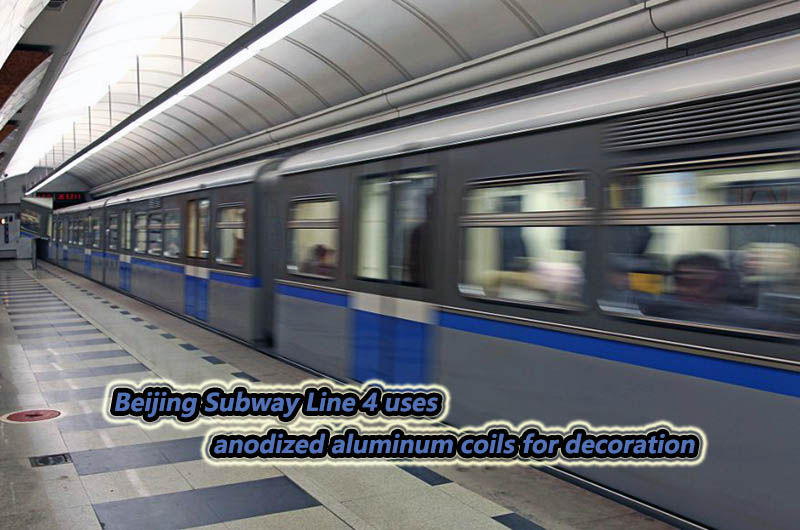

1. Subway station – Beijing Subway Line 4

Beijing Subway Line 4 uses anodized aluminum coils for platform decoration. Through the combination of different colors and designs, a modern and fresh platform environment is created. This not only improves the travel experience for passengers, but also makes the subway station a unique and artistic place in the city.

2. Station – London King’s Cross Station

Anodized aluminum sheet rolls were used in the interior decoration of London's King's Cross railway station. Through the special treatment of the aluminum plates, a unique metallic texture is created, making the interior space of the station more fashionable and technological.

3. Exhibition Hall - Louvre Museum, Paris

Some exhibition halls of the Louvre Museum in Paris use anodized aluminum sheet rolls, showing a unique exhibition atmosphere through the application of different colors and artistic design. This decoration not only conforms to the artistic atmosphere of the Louvre, but also provides the audience with an immersive artistic experience.

4.Mall - Tokyo Disney Mall

Tokyo Disney Shopping Center uses anodized aluminum sheet rolls for exterior wall decoration. Through the combination of different colors, the mall's appearance is colorful and attracts a large number of tourists. The durability of aluminum panels also ensures that the mall's appearance remains in good condition for a long time.

5. Airport – Singapore Changi Airport

Anodized aluminum sheet rolls are used to decorate some public areas at Singapore Changi Airport. This not only enhances the overall image of the airport, but also provides passengers with a comfortable and stylish waiting environment. Different areas use different colors and designs to present a diverse spatial experience.

These examples demonstrate the flexible application of anodized aluminum sheet rolls in different types of public spaces, adding unique design charm and ornamental value to buildings and interior spaces.

Informations you may be interested in:

- How to clean anodized aluminum sheet coil roll

- Reasons for irregular oxide film of alloy aluminum coil

- What is anodized aluminum sheet coil?

- What skills are needed for hard anodized of 5052 aluminum coils?

- 5 features continuous thick film anodized aluminum coils

- Haomei Aluminum An Overview of the Different Types of Aluminum Coil Stock