- Why choose 8006 aluminum foil for airline lunch boxes?

- Learn about 8006 aluminum foil

- Advantages of 8006 aluminum foil for airline lunch boxes

- Haomei Aluminum provides services about Airline lunch box material 8006 aluminum foil

- Conclusion

Aluminum foil lunch boxes are widely used in all walks of life, especially in the aviation field, where they have become a common choice for tableware. Behind this trend, it mainly benefits from the excellent performance of aluminum foil lunch boxes in terms of thermal conductivity, heat preservation effect, convenient heating and storage.

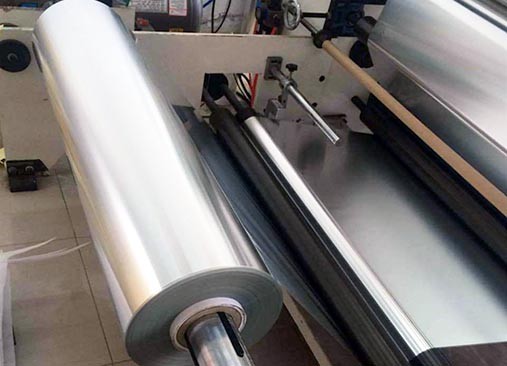

Aviation aluminum foil lunch boxes are mostly wrinkle-free lunch boxes, made of 8006 aluminum foil, which are formed by one-time fully automatic cold stamping with special equipment and molds.

Why choose 8006 aluminum foil for airline lunch boxes?

Common alloys used in aluminum foil for lunch box manufacturing are 3003, 3004, 8006 and 8011. However, the decision to choose 8006 aluminum foil for aviation lunch boxes is based on the fact that 8006 alloy has some unique advantages in the aviation field:

- Corrosion resistance: 8006 aluminum foil has stronger corrosion resistance than 3003 and 3004 aluminum foil. In the aviation field, aviation lunch boxes are often affected by high-altitude humidity and varying temperatures, so they have higher requirements for corrosion resistance.

- Strength and toughness: 8006 aluminum foil has better strength and toughness than 8011 aluminum foil. This makes the 8006 aluminum foil easier to shape during the manufacturing process and can better resist external pressure and collision during use, improving the safety of aviation lunch boxes.

- Forming performance: Compared with 3003 and 3004 aluminum foil, 8006 aluminum foil is easier to form during the manufacturing process. This formability advantage allows the production line to more efficiently manufacture lunch boxes of various shapes and sizes to meet the diversity needs of airlines.

- High temperature stability: Compared with 3003 and 3004 aluminum foil, 8006 aluminum foil is more stable under high temperature conditions. In the use of airline lunch boxes, heating may be required. 8006 aluminum foil can stably maintain its structure and performance and will not fail in high temperature environments.

- Environmental sustainability: 8006 aluminum foil is a recyclable material, which makes it more environmentally friendly and sustainable than disposable plastic lunch boxes. With today's society paying close attention to sustainability, airlines' choice to use recyclable materials is in line with industry and social expectations.

Based on these considerations, 8006 aluminum foil has comprehensive advantages in the application of aviation lunch boxes, making it the first choice material. Its special physical properties and environmentally friendly attributes enable 8006 aluminum foil to better meet the requirements of aviation lunch boxes for corrosion resistance, strength, molding performance, high temperature stability and environmental sustainability.

Learn about 8006 aluminum foil

8006 aluminum foil is a special container foil product with a tensile strength between 123-135. It has no wrinkles on the edges after stamping and has a smooth and smooth appearance.

composition and structure

8006 aluminum foil is an aluminum alloy with a unique composition that combines aluminum, iron, silicon and other trace elements. The foil is manufactured through a meticulous process that ensures a specific structure, resulting in a material that is both durable and versatile.

Mechanical behavior

8006 aluminum foil has excellent mechanical properties, including high tensile strength, elongation and formability. These properties make it ideal for creating complex shapes and ensuring the design integrity of airline lunch boxes.

Advantages of 8006 aluminum foil for airline lunch boxes

1. Light weight and space saving

One of the outstanding features of 8006 aluminum foil is its lightweight nature. Airlines are always looking for ways to reduce the overall weight of items on board to improve fuel efficiency. The lightweight nature of 8006 aluminum foil allows the creation of compact and space-saving lunch box designs without compromising durability.

2. Temperature resistance

Airline meals usually need to withstand a certain temperature during storage and transportation. 8006 aluminum foil has excellent temperature resistance and can effectively block heat and cold. This ensures that the contents of the lunch box remain fresh and tasty, creating a positive dining experience for passengers.

3. Corrosion resistance

The aviation environment exposes materials to a variety of corrosive factors, including changes in humidity and atmospheric pressure. 8006 aluminum foil is inherently corrosion-resistant, making it ideal for protecting the contents of airline lunch boxes from environmental factors that may affect their quality.

4. Barrier performance

8006 aluminum foil has excellent moisture-proof, light-proof and gas-proof barrier properties. This quality is essential to maintain the freshness of the food inside the lunch box and prevent external factors from affecting its taste and quality. The foil acts as a protective shield, ensuring that the meal reaches the passenger in optimal condition.

5. Recyclability

As sustainability becomes an increasingly important consideration for consumers and businesses, the recyclability of materials becomes a key factor in decision-making. 8006 aluminum foil is highly recyclable, helping the aviation industry reduce its environmental footprint and adopt environmentally friendly practices.

Haomei Aluminum provides services about Airline lunch box material 8006 aluminum foil

1. Customizable design

The versatility of 8006 aluminum foil allows for the creation of customizable lunch box designs. Airlines can enhance the overall dining experience by incorporating innovative shapes and sizes to suit different passenger preferences.

2. Compatibility with food safety standards

8006 aluminum foil is approved for direct contact with food and meets strict safety standards. This ensures that air passengers can enjoy their meals without having to worry about harmful substances potentially migrating from the packaging into the food.

3. Printing ability

The surface of 8006 aluminum foil provides an excellent printing substrate, allowing airlines to imprint logos, images and messages on their meal packaging. This not only enhances the aesthetics of the meal box, but also serves as a marketing tool for the airline.

Conclusion

The choice of 8006 aluminum foil for making airline lunch boxes is based on its superior performance and the many advantages it brings to the aviation industry. From its lightweight, space-saving properties to its temperature resistance, corrosion resistance and recyclability, 8006 aluminum foil stands out as a material that can meet the ever-changing needs of the aviation industry.

As airlines continue to prioritize the passenger experience, the use of 8006 aluminum foil in the creation of lunch boxes demonstrates the industry’s commitment to providing high-quality, sustainable and visually appealing in-flight catering solutions.

Informations you may be interested in:

- 8021 Food Aluminum Foil

- 8021 Aluminum Foil in Yogurt Lid Applications

- 8011-O aluminum foil for lunch boxes

- 3004 aluminum foil for single cavity lunch box

- Is it safe to pack food in aluminum foil?

- 8011 8079 Aluminum foil for yogurt lid

- 8011 Aluminium Foil for Air Fryer

- 8011 h18 Aluminium Foil for Baking

- 8011 Aluminum Foil in Toaster

- Aluminum foil is safe to use in the microwave