- 6063 Aluminum for Motor Housings Properties

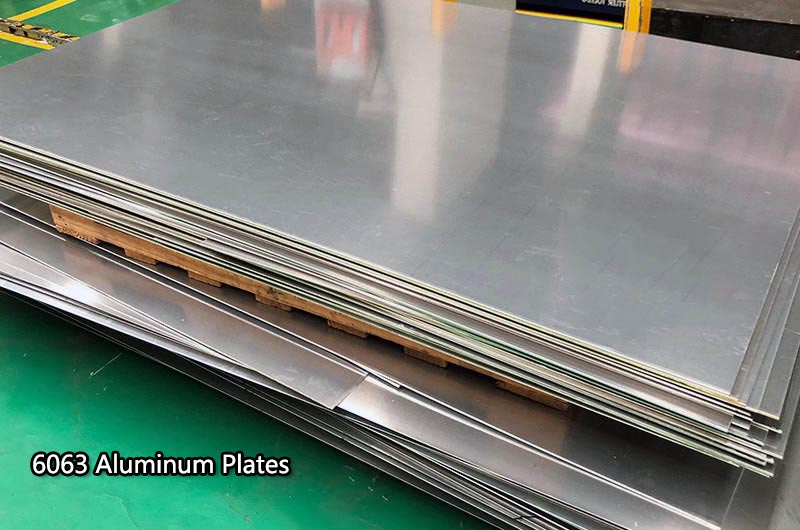

- 6063 Aluminum Plate for Motor Shell Specifications

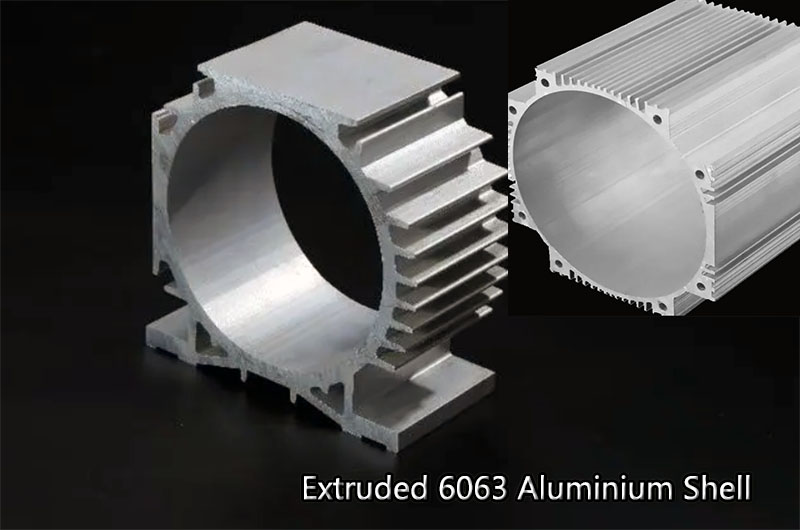

- Extruded 6063 Aluminum Motor Enclosure

- 6063 Aluminum Plate Cost for Motor Housing

The motor shell, also known as the motor housing or motor enclosure, is the enclosure that protects the internal parts of the motor. It provides structural integrity, thermal management and electrical insulation. Aluminum is often the first choice for motor housings due to its light weight, good thermal conductivity and corrosion resistance.

The aluminum alloy motor casing is light in weight, has good heat dissipation performance, good thermal conductivity, easy processing, good plasticity, high elongation, good shape, high cleanliness, energy saving and environmental protection, and can be reused High value, is a new green product.

6063 aluminum alloy is a material widely used in various industries, including automotive, construction and electrical industries. It is known for its excellent extrudability and good mechanical properties. For motor housings, 6063 aluminum may be a suitable choice depending on specific application requirements.

6063 Aluminum for Motor Housings Properties

- Lightweight : 6063 aluminum is a lightweight alloy that helps reduce the overall weight of the motor. This is advantageous for applications where weight is a critical factor, such as in the automotive or aerospace industries.

- Good thermal conductivity : Aluminum has excellent thermal conductivity and can effectively dissipate heat from the motor. This helps maintain an optimal operating temperature and prolongs the life of the motor.

- Corrosion Resistance : 6063 aluminum alloy is known for its good corrosion resistance, especially when compared to other metals such as steel. This feature ensures that the motor housing can withstand moisture, chemicals and environmental elements, increasing durability and reliability.

- Extrudability : 6063 aluminum is highly extrudable, meaning it can be easily shaped and formed into intricate designs. This enables the creation of motor housings with complex features or custom shapes to meet specific design requirements.

- Electrical insulation : Aluminum is a non-magnetic material with electrical insulating properties. This prevents electromagnetic interference and ensures efficient and safe operation of the motor.

While 6063 aluminum offers many advantages, the choice of motor housing material depends on factors such as motor size, power requirements, operating conditions and environmental considerations.

6063 Aluminum Plate for Motor Shell Specifications

- Thickness : 0.3-600mm

- Width : 500-2650

- Length : 500-16000

- Material state : F, O, H112, T4, T6, T651

- Applicable fields : automobile floor, motor casing, truck wheel hub, mobile phone casing, precision mold, etc.

Extruded 6063 Aluminum Motor Enclosure

Extruded 6063 aluminum motor housings refer to motor housings or enclosures manufactured using 6063 aluminum alloy extrusion process. Extrusion is a manufacturing method in which a material (aluminum in this case) is forced through a die to form a specific shape.

Extruded 6063 aluminum motor housing combines structural strength, lightweight design, thermal management and customization options. These housings are widely used in various motor applications across different industries including automotive, HVAC, industrial machinery and more.

The construction of motor housings made of 6063 aluminum alloy may vary depending on the specific motor design and application. However, here is a general description of a typical structure :

- Cylindrical : Motor housings are usually cylindrical to accommodate the internal motor components. The cylindrical construction provides structural integrity and allows for easy installation and integration into overall motor systems.

- End caps : Motor housings usually have two end caps, one at each end, that are securely fastened to the cylinder. These end caps provide a sealed enclosure for the motor and help protect internal components from dust, moisture and other contaminants.

- Mounting Features : Motor housings may have mounting features, such as flanges or brackets, to facilitate attachment of the motor to other components or mounting surfaces. These features ensure the stability and correct positioning of the motor within the system.

- Cooling Fins : In some cases, there may be cooling fins or ribbed structures on the outer surface of the motor housing. These fins increase the surface area of the motor housing, enhancing heat dissipation and improving the overall thermal management of the motor.

- Openings and Ports : Motor housings may have various openings and ports for electrical connections, cable entry, ventilation, or other purposes. These openings are carefully positioned to allow for cabling, cooling airflow, or other necessary functions.

- Material Thickness : The thickness of 6063 aluminum alloy used for the motor casing can vary according to factors such as motor size, operating conditions and structural requirements. The thickness is usually designed to provide sufficient strength and rigidity while keeping the weight of the motor housing relatively low.

The construction of the motor housing can be highly customized according to the specific motor design and requirements. The features and characteristics described above are common in motor housings made of 6063 aluminum, but actual construction may vary widely depending on the intended use and design specifications of the motor.

6063 Aluminum Plate Cost for Motor Housing

How much is a ton of 6063 aluminum plate for motor housing? Presumably this is a question that most users want to know. Generally speaking, the higher the quality of the product, the better the performance, and the corresponding price will be slightly higher.

The old manufacturer of 6063 aluminum plate for large-scale motor housing has rich experience in production technology. After years of practice, it will consider more comprehensively in the development and production of equipment to meet the actual needs of users.

Because the price of 6063 aluminum plate for motor casing is affected by many factors such as the manufacturer, geographical location, product quality, and model specifications, the price of 6063 for motor casing on the market is not consistent.

If you want to get the detailed price of 6063 aluminum plate for motor casing, you need to contact the specific manufacturer. You can directly contact the manufacturer to purchase the product. You can enjoy the ex-factory price, avoid the middleman to make the difference, and save investment costs.

Haomei Aluminum is an old manufacturer with more than 20 years of experience in the production of strips and foils. The standardized production workshop and strict product quality inspection standards ensure that every product that leaves the factory reaches a high quality level. Haomei Aluminum is an aluminum processing enterprise integrating R&D, production and sales. The products are all ex-factory prices, there is no middleman to make the difference, and the quality is guaranteed and the price is more favorable.