- Is Aluminum Sheet good for Roofing?

- Aluminum Roof Panels Advantages and Disadvantages

- How Thick is Aluminum for Roofing?

- Which is the Best Aluminum Sheet for Roofing?

- Typical Aluminum Roofing Sheet

- Aluminum Roofing Sheet Price

Is Aluminum Sheet good for Roofing?

Yes, aluminum panels are a popular choice for roofing due to their light weight, durability, and resistance to rust and corrosion.

When choosing to use Aluminum Sheet for Roof, it is important to consider the thickness or gauge of the sheet. Thicker aluminum roof panels will be more durable and provide better insulation, but can also be more expensive. The most common gauges for aluminum roof panels are between 0.016 inches (0.4 mm) and 0.040 inches (1.0 mm).

The specific alloys and tempers used for Aluminum Sheet for Roof may vary by manufacturer and application. Aluminum alloys commonly used for roofing include 3003 and 5052, both of which are highly corrosion resistant and easy to machine. The state of the alloy may also vary, some roofing materials use annealed or tempered aluminum. The specifications for each Aluminum Sheet for Roof will depend on the specific application, such as the required sheet thickness, width and length.

Aluminum Roof Panels Advantages and Disadvantages

Aluminum shingles have several advantages and disadvantages that should be considered when choosing a roofing material.

Aluminum Roof Panels Advantages

- Lightweight : Aluminum is a lightweight material that is easy to transport and handle during installation. This also reduces the overall weight of the roof, which benefits the structural integrity of the building.

- DURABLE : Aluminum is a durable material that resists corrosion and rust, making it ideal for outdoor applications. It's also able to withstand extreme temperatures, which helps maintain its structural integrity over time.

- Easy to Shape : Aluminum is a malleable material that can be easily shaped to fit the contours of the roof. This makes it a versatile material that can be used in a variety of roof shapes and sizes.

- Low Maintenance : Aluminum shingles require very little maintenance because they don't need to be painted or coated to maintain their appearance or prevent corrosion. This helps reduce the overall cost of maintaining your roof over time.

- Energy efficient : Aluminum roof panels reflect sunlight and heat, which helps reduce the amount of heat absorbed by the roof. This helps reduce energy costs for cooling buildings.

Aluminum Roof Panels Disadvantages

- Cost : Aluminum shingles can be more expensive than other roofing materials, such as asphalt shingles or metal roofs.

- Noise : During periods of heavy rain or hail, aluminum shingles can be noisy, which can be a concern for some homeowners.

- Expansion and Contraction : Aluminum shingles expand and contract with temperature changes, which can cause fasteners to loosen over time. This can lead to leaks and other roof problems if not done properly.

- Conductivity : Aluminum is a highly conductive material, which makes it a poor insulator in some applications. This can lead to increased energy costs for heating buildings during the cooler months.

Aluminum shingles are a popular choice for many roofing applications due to their durability, light weight and low maintenance requirements. However, it is important to carefully consider the specific pros and cons of aluminum roofing panels for a particular project before making a final decision.

How Thick is Aluminum for Roofing?

Aluminum roofing panels can vary in thickness depending on the specific application and requirements of the project. However, the most common specifications for aluminum roof panels

Thickness : 0.016" (0.4mm) - 0.040" (1.0mm)

The thickness of aluminum sheet selected for a roof will depend on factors such as expected wind loads, snow loads and other environmental factors to which the roof will be exposed. Thicker boards generally provide more durability and better insulation, but can also be more expensive.

It is important to consult a roofing professional or supplier to determine the proper aluminum sheet thickness for a particular roofing project based on required load capacity and other project-specific considerations.

Which is the Best Aluminum Sheet for Roofing?

There is no one "best" aluminum roofing sheet, as the best sheet for a particular project will depend on various factors, such as the specific application, environmental considerations, and budget. However, there are a few things to keep in mind when choosing aluminum panels for your roof :

- Specifications : The thickness of the aluminum sheet will depend on factors such as expected wind loads, snow loads and other environmental factors to which the roof will be exposed. Thicker boards generally provide more durability and better insulation, but can also be more expensive.

- Coating/Finish : The finish or coating on an aluminum panel can affect its appearance and weatherability. Common finishes for aluminum shingles include satin, painted and anodized. It is important to choose a coating that is suitable for the specific environmental conditions of the project.

- Durability : Aluminum shingles should be resistant to corrosion and rust, and be able to withstand extreme temperatures. It is important to choose high-quality panels that can withstand local environmental conditions.

- Cost : The cost of an aluminum sheet will depend on its thickness, finish, and other characteristics. It is important to choose a panel that is within the project budget while still meeting the required specifications.

- Manufacturer/Supplier : It is important to choose a reputable manufacturer or supplier who can provide quality products and provide technical support and advice.

The best aluminum roofing panels will depend on the specific requirements and circumstances of the project. It is recommended to consult a roofing specialist or supplier to determine the best aluminum sheet for a particular roofing project.

Typical Aluminum Roofing Sheet

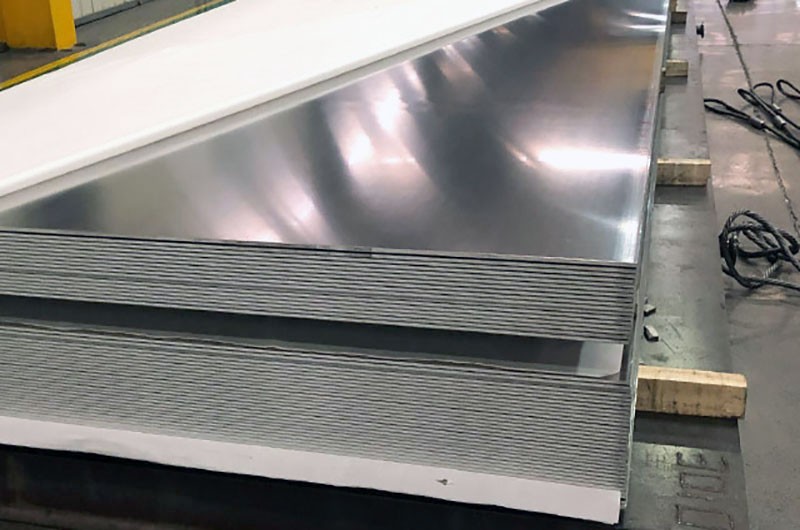

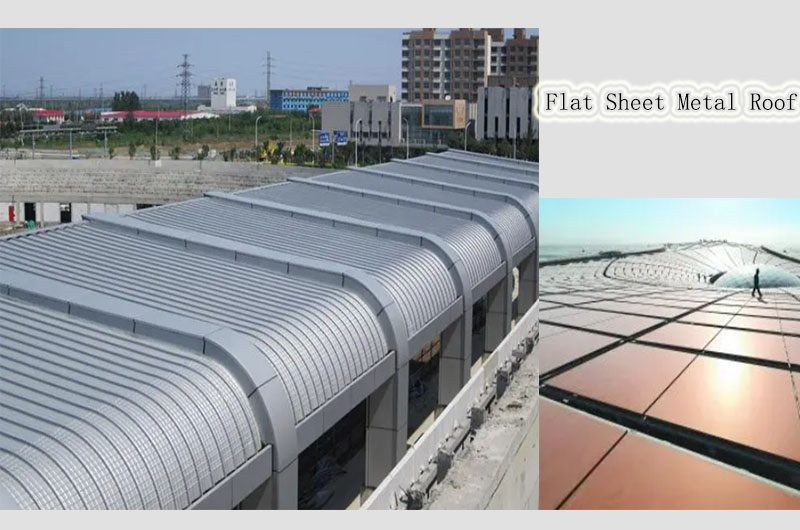

Flat Sheet Metal Roof

Flat Sheet Metal Roof is used in industrial and commercial buildings and can also be used in residential.

- They are usually made of aluminum or steel and come in various thicknesses and finishes.

- Advantages of flat metal roofs : include durability, low maintenance, and energy efficiency.

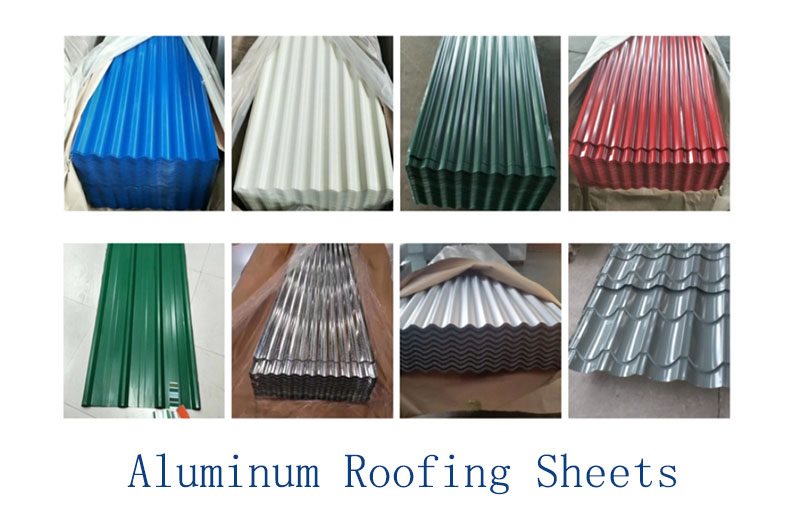

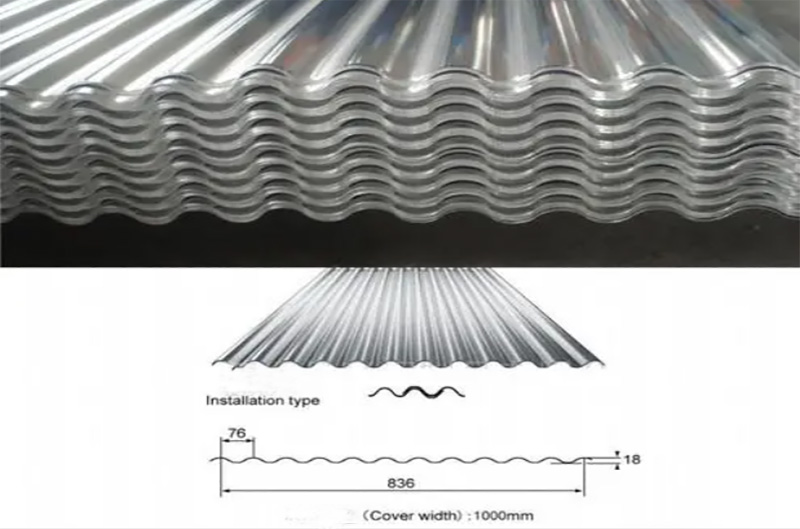

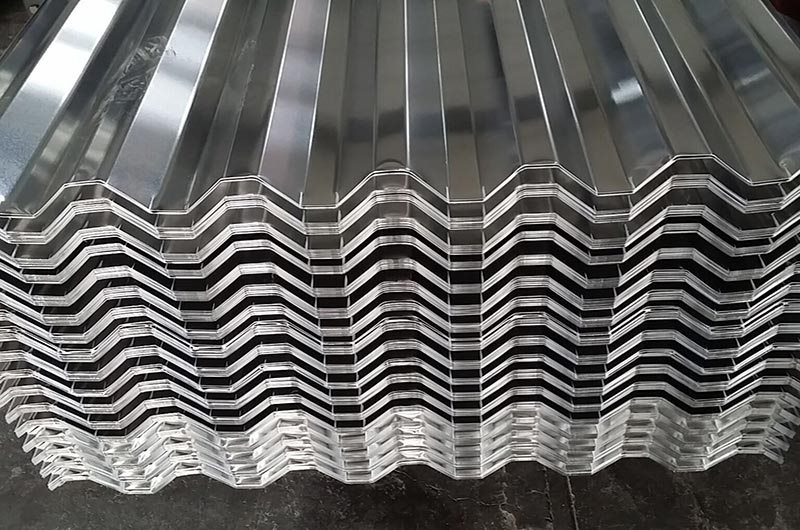

Aluminum Corrugated Roof Panels

Aluminum Corrugated Roof Panels are commonly used in residential and commercial roofing applications. They are lightweight and easy to install, and are available in a variety of colors and finishes. Advantages of aluminum corrugated roofing sheets include durability, resistance to corrosion and rust, and energy efficiency.

Corrugated Aluminum Roofing Sheets

Corrugated Aluminum Roofing Sheets are able to withstand harsh weather conditions, resist corrosion and rust, and are energy efficient.

- Advantages : They are lightweight, durable and easy to install, and are available in a variety of colors and finishes.

- Application : Typically used in industrial, commercial and residential roof applications.

Step Tiles Aluminum Roofing Sheet

Step Tiles Aluminum Roofing Sheet has a unique shape design that gives them a sleek and modern look.

- Pros : Including durability, low maintenance and energy efficiency.

- Application : Step Tiles Aluminum Roofing Sheet is commonly used in residential and commercial roofing applications.

Aluminum Composite Panel Roof

Aluminum Composite Panel Roof is constructed from a combination of aluminum and plastic and is available in a variety of colors and finishes.

- Pros : Include ability to withstand harsh weather conditions, resistance to corrosion and rust, and low maintenance requirements.

- Aluminum composite panel roofs are commonly used in commercial and industrial buildings.

Zinc Aluminum Roofing Sheets (Galvanized Sheet Metal Roofing)

Zinc Aluminum Roofing Sheets (Galvanized Sheet Metal Roofing) are made from a combination of zinc and aluminum and are available in a variety of colors and finishes.

- Pros : Including durability, corrosion and rust resistance, and energy efficiency.

- Galvanized roofing (galvanized sheet metal roofing) is commonly used in residential and commercial roofing applications.

Long Span Aluminum Roofing Sheet

Long Span Aluminum Roofing Sheet has a unique shape design to achieve large spans without additional support.

- Pros : include durability, resistance to corrosion and rust, and low maintenance requirements.

- Long Span Aluminum Roofing Sheet is commonly used in industrial and commercial buildings.

24 Gauge Corrugated Metal Roofing

24 Gauge Corrugated Metal Roofing is constructed of steel or aluminum and is available in a variety of colors and finishes.

- Benefits of a 24 gauge corrugated metal roof include its durability, resistance to corrosion and rust, and energy efficiency.

- 24 gauge corrugated metal roofing is commonly used in residential and commercial roofing applications.

Aluminum Ibr Roof Sheeting

Aluminum Ibr Roof Sheeting has a trapezoidal shaped interlocking rib profile that provides excellent strength and water resistance.

- Pros : Including its durability, resistance to corrosion and rust, and low maintenance requirements.

- Aluminum Ibr Roof Sheeting is commonly used in commercial and industrial roofing applications.

Aluminum Roofing Sheet Price

The price of aluminum shingles can vary based on a number of factors, including the thickness of the shingle, the type of shingle, and the supplier. Generally speaking, the aluminum roofing sheet price per sq ft needs to consult the factory, the manufacturer.

It is important to note that prices may also vary depending on the location and availability of shingles and the quantity purchased. Consult Haomei Aluminum to get the exact price for the specific type and quantity of Aluminum Roof Sheets you need.