- Specifications of 5052 aluminum checkered plate for oil tanker

- Chemical composition of 5052 aluminum checkered plate for oil tanker

The use of 5052 Aluminum Checkered Plate in the construction of tanker components such as floors, stairs or other structural elements offers several advantages.

For tanker applications, using 5052 Aluminum Checkered Plate provides several advantages:

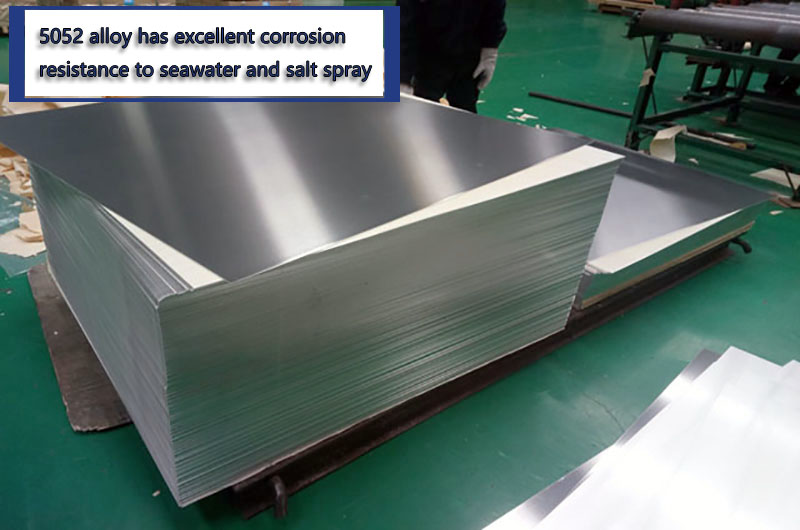

- Corrosion Resistance: Aluminum, especially alloy 5052, is known for its excellent corrosion resistance, making it ideal for marine and offshore applications.

- Lightweight: Aluminum is a lightweight material that helps improve fuel efficiency and load-carrying capacity in transportation applications such as tankers.

- Strength: While not as strong as some other alloys, 5052 still offers good strength for its weight, making it suitable for applications where strength and weight balance is critical.

- Ease of Maintenance: Aluminum is relatively easy to maintain and does not require painting for corrosion protection.

Specifications of 5052 aluminum checkered plate for oil tanker

Specifications of 5052 aluminum checkered plate for tanker applications depend on a variety of factors, including the specific requirements of the tanker design, industry standards and regulations.

5052 aluminum checkered plate for oil tanker temper

Condition: The condition name of 5052 aluminum pattern plate is usually H32, indicating that it has been strain hardened and stabilized.

5052 aluminum checkered plate for oil tanker thickness

The thickness of the pattern plate depends on the structural requirements of the tanker. Common thicknesses of patterned aluminum sheets range from 1.5 mm to 6 mm or more.

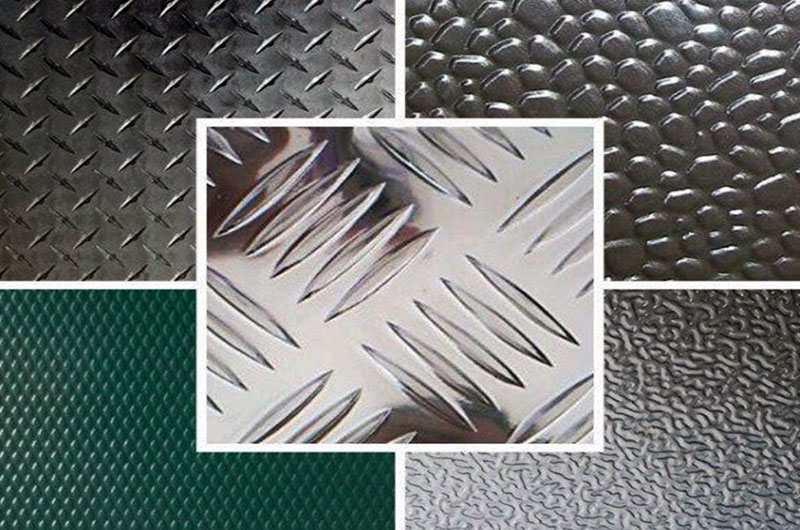

Type 5052 aluminum checkered plate for oil tanker

The surface of the plaid board has a raised pattern, usually in a diamond or strip pattern. The size of the pattern can vary depending on the intended application.

- Diamond 5052 aluminum checkered plate for oil tanker

- Lentil shape 5052 aluminum checkered plate for oil tanker

- 5 Bar 5052 aluminum checkered plate for oil tanker

- 3 Bar 5052 aluminum checkered plate for oil tanker

5052 aluminum checkered plate for oil tanker width and length

The width and length of the tread plate depend on the design specifications of the tanker. Standard widths and lengths are usually available, but custom sizes can also be produced.

5052 aluminum checkered plate for oil tanker surface finish

The surface of the aluminum checkered plate can have a milled finish or can be coated/painted for additional protection or aesthetic purposes.

- Anodized 5052 aluminum checkered plate

- Coated 5052 aluminum checkered plate

- Polished 5052 aluminum checkered plate

- Spray-coated 5052 aluminum pattern plate

Anodized 5052 aluminum checkered plate

- Advantages: Improved corrosion resistance, increased surface hardness, and potential for color customization.

- Application: Anodized aluminum checkered panels are commonly used in environments where corrosion resistance is critical.

Coated 5052 aluminum checkered plate

Type of coating: Coatings can include a variety of materials such as paint, varnish, or other protective coatings.

- Benefits: Enhanced corrosion protection, aesthetics and appearance customization.

- Application: Coated aluminum checkered panels are used where both protection and visual appeal are important.

Polished 5052 aluminum checkered plate

Polishing process: Mechanical or chemical polishing of the aluminum surface to achieve a smooth and shiny surface.

- Advantages: Improve aesthetics, enhance reflectivity, and have a fashionable appearance.

- Applications: Polished aluminum checkered panels are often used in decorative or architectural applications where a visually appealing finish is required.

Spray-coated 5052 aluminum pattern plate

Spraying techniques: This may involve applying protective coatings or paints via spraying methods.

- Pros: Quick application, even coverage, customizable.

- Applications: Spray-coated aluminum checkered panels can be used in a variety of applications where a protective layer is required, such as outdoors or in industrial settings.

5052 aluminum checkered plate for oil tanker quality

Ensure aluminum checkered plates comply with relevant industry standards and specifications. For example, ASTM B209 is a common reference standard for aluminum and aluminum alloy sheet materials.

quality assurance:

Quality control, inspection and testing considerations should be part of the specification to ensure materials meet required standards and perform as expected. Inspections include surface flatness, pattern clarity, edge condition, etc. to ensure there are no obvious defects, deformation or damage.

Chemical composition of 5052 aluminum checkered plate for oil tanker

| Element | Composition % |

| Si | 0.25 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.10 |

| Mg | 2.2-2.8 |

| Cr | 0.15-0.35 |

| Ni | - |

| Zn | 0.10 |

| Ti | - |

| Al | Remainder |

Informations you may be interested in:

- 3003 Oil Tanker Aluminum Checkered Plate

- Application and precautions of aluminum plates in tank truck manufacturing

- What are the advantages of using 5182-H111 aluminum plates for tank truck materials?

- Tank truck bodies made of aluminum alloy are safer

- 5 series aluminum plate for semi-trailer tank truck

- 5083 H321 Aluminum Plate : An In-depth Look Performances and Applications