- 5005 Anodized Aluminum Plate Performance

- 5005 Anodized Aluminum Plate uses

- 5005 aluminum plate oxidation treatment technology

- Surface characteristics

- How much does a ton of 5005 aluminum plate for oxidation cost?

A thin layer of aluminum oxide is formed on the surface of the anodized aluminum plate. After oxidation, the 5005 aluminum plate has improved hardness and wear resistance, has good heat resistance, insulation, corrosion resistance, and good coloring effect.

5005 anodized aluminum plates can be seen in industries such as mechanical parts, precision instruments, architectural decoration, machine casings, and interior decoration.

5005 Anodized Aluminum Plate Performance

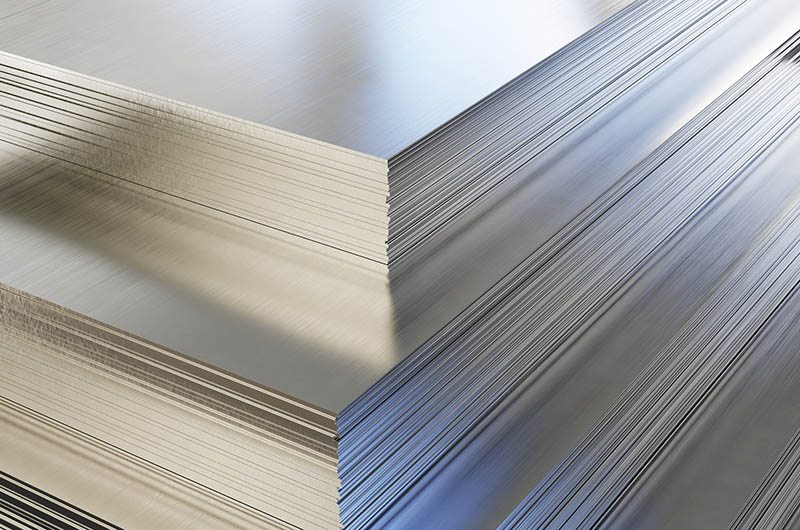

5005 aluminum plate and strip has medium strength, good corrosion resistance and processability, and its strength is equivalent to 3003. The anodized film is brighter than the oxide film on the 3003 alloy and is consistent with the color tone of the 6063 alloy.

1. Corrosion resistance

5005 aluminum plate has excellent corrosion resistance, especially strong resistance to salt water corrosion. This makes it ideal for use in marine environments and humid climates, such as marine equipment and building cladding.

2. Forming performance

> 5005 aluminum plate excels in cold, hot rolling and deep drawing forming. Its high degree of plasticity makes it suitable for various forming processes, including stretching, bending and pressure forming, etc., thereby meeting the needs of different industries.

5005 Anodized Aluminum Plate uses

5005 aluminum plate is a commonly used aluminum alloy material and is therefore widely used in various applications.

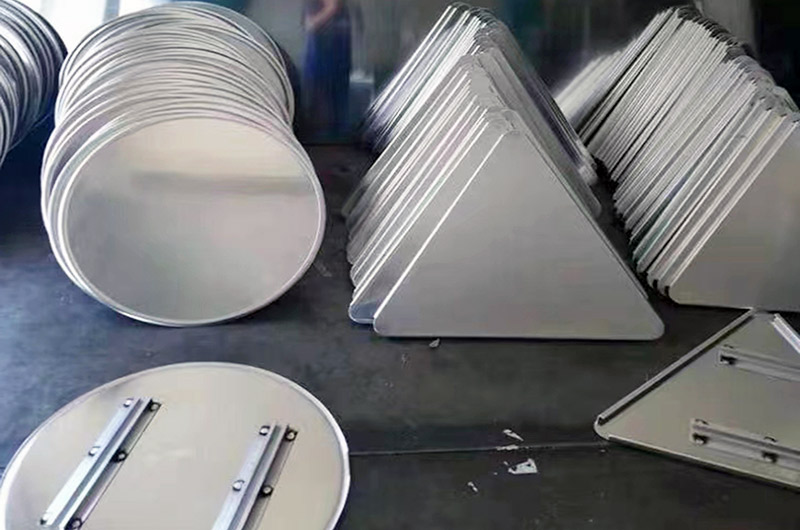

5005 aluminum plates are commonly used in cookware, instrument panels, building decorations, building materials, interior and exterior materials, vehicle interior materials, etc.

5005 Anodized Aluminum Plate for cookware

Temper: H34 (semi-hard)

Specifications: Usually between 0.5mm and 4.0mm, depending on specific cookware design needs.

5005 Anodized Aluminum Plate for instrument panel

- Temper: H32 (soft), H34 (semi-hard)

- Specifications: Common thicknesses range from 1.0mm to 3.0mm, depending on the instrument panel application and design.

5005 Anodized Aluminum Plate for architectural decorative parts

- Temper: H32 (soft), H34 (semi-hard)

- Specifications: Usually between 1.0mm and 4.0mm, depending on the specific architectural decoration requirements.

5005 Anodized Aluminum Plate for building materials and interior and exterior materials

- Temper: H32 (soft), H34 (semi-hard)

- Specifications: The thickness can be between 1.0mm and 4.0mm. The specific specifications will be determined according to the internal and external decoration requirements of the building materials.

5005 Anodized Aluminum Plate for vehicle interior materials

- Temper: H34 (semi-hard)

- Specifications: The thickness is generally between 1.0mm and 3.0mm, adapting to the lightweight and durability requirements of vehicle interiors.

It should be noted that these are just some common Tempers and specifications, and the specific selection should be determined based on specific engineering requirements, mechanical performance requirements, and relevant standards. Before making a selection, it is recommended to have a detailed discussion with the Aluminum Plate manufacturer or supplier to ensure that the selected 5005 Anodized Aluminum Plate meets the requirements of the specific application.

As a base material for oxidation treatment, 5005 aluminum plate has broad application prospects in the following fields in addition to the above common applications.

- Construction field: 5005 alumina panels are commonly used in building exterior walls, roofs, doors and windows, and their oxidation treatment can provide longer-lasting protection.

- Automobile manufacturing: Due to its lightweight and good formability, 5005 alumina sheet is used in automobile manufacturing for body panels.

- Electronic products: In some electronic products that require higher appearance and thermal conductivity, 5005 aluminum plates have also found applications.

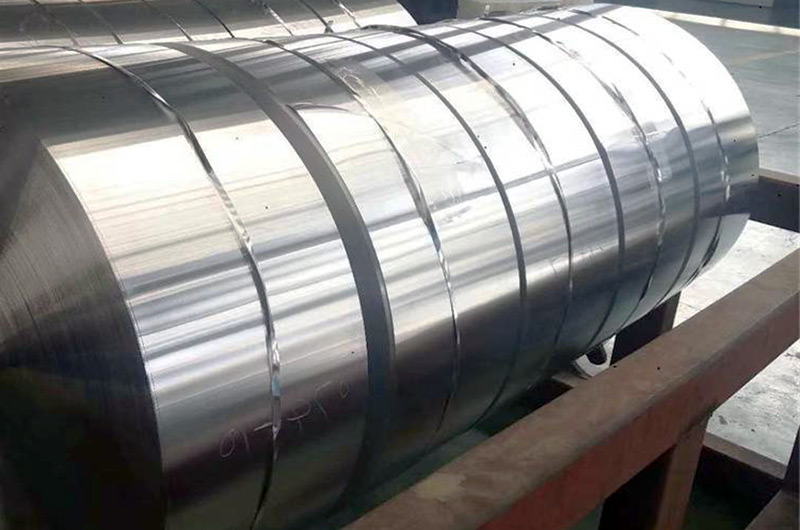

5005 aluminum plate oxidation treatment technology

5005 aluminum plates are often oxidized to enhance their surface properties. Oxidation treatment is a process that forms an oxide layer on the surface of aluminum to improve its hardness, wear resistance and corrosion resistance. This treatment can be by methods such as anodizing or chemical oxidation, depending on the requirements of the application.

Surface characteristics

The surface of the oxidized 5005 aluminum plate usually presents a uniform oxide layer, providing better appearance and corrosion resistance. This makes it particularly popular in applications where appearance is critical, such as architectural decoration and interior design.

As a recyclable material, 5005 aluminum plate meets the environmental protection requirements of modern society. Both its production and regeneration processes require relatively low energy consumption, helping to reduce dependence on natural resources.

How much does a ton of 5005 aluminum plate for oxidation cost?

The price of aluminum plates is composed of "the average closing price of Yangtze River spot A00 aluminum ingots on the day of delivery + processing fee" and is related to the manufacturer's strength and product specifications.

At present, there are many 5005 aluminum plate manufacturers in China. Among these manufacturers, the scale, nature of the manufacturer, strength level, etc. are all different, and the quotations for aluminum plates are also different.

It is recommended that users choose large-scale, direct-selling, and strong manufacturers to purchase products. The quality is more guaranteed and the quotation is more reasonable.

Haomei Aluminum is a large-scale aluminum plate manufacturer that has been engaged in the production and processing of aluminum plates, strips and foils for more than 20 years. To know the specific price of 5005 aluminum plate, please provide the required thickness, width, length (mm), and total demand (tons).

Informations you may be interested in: