- 1. Long-term discoloration stability

- 2. Guarantee of production consistency

- 3. High hardness, wear resistance and scratch resistance.

- 4. Corrosion-resistant and easy-to-clean environmentally friendly features

- 5. Maintain high-end atmosphere with metallic luster and texture

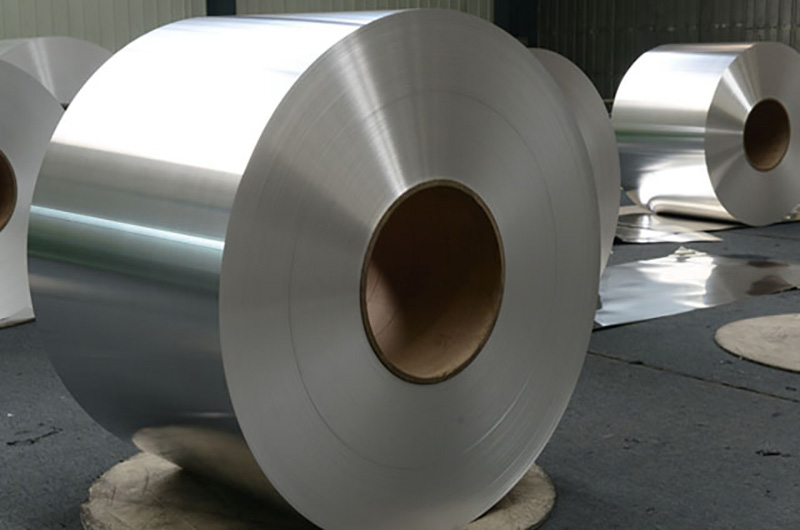

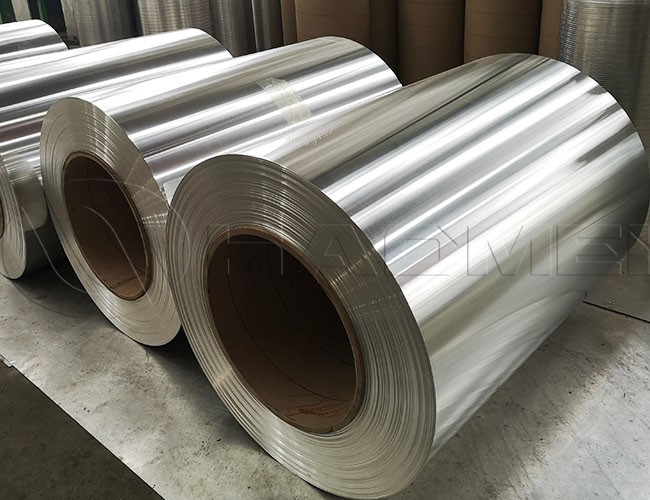

In modern architecture, aluminum continuous thick film anodized aluminum coils have become a highly respected building material due to their unique properties and are widely used in various construction projects.

1. Long-term discoloration stability

Aluminum continuous thick film anodized plate rolls are electrolytically colored during the production process, and the thickness of the oxide film formed reaches 20um, which allows it to withstand the test of time and not change color for up to 50 years. This characteristic gives the building its longevity.

Example 1: Mercedes-Benz Building

The Mercedes-Benz Building is a building with a history of more than 60 years, using aluminum continuous thick film anodized aluminum coils. After the test of time, the building's exterior remains as bright as new, demonstrating the material's excellent color stability.

Example 2: Tokyo Tower

Tokyo Tower is also a typical example of aluminum continuous thick film anodized aluminum coils. After years of climate change in Japan, its exterior walls are still able to maintain their metallic texture without obvious color changes.

2. Guarantee of production consistency

The use of ultra-long production lines and computer automatic control throughout the process is an advanced method for the production of aluminum continuous thick film anodized coils. This not only ensures the consistency of the thickness and color of the oxide film, but also controls the color difference of products in the same batch to within 0.6, and the color difference of products in different batches to within 1.0.

Example 1: Dalian International Conference Center

Dalian International Conference Center uses aluminum continuous thick film anodized coils, which are used for large-area exterior wall decoration, so that there is no obvious color difference in the appearance of the entire building, which meets the high standards of curtain appearance.

Example 2: Expansion of the Louvre Museum in Paris

In the Louvre Museum expansion project, aluminum continuous thick film anodized aluminum coils were widely used. Through strict production control, the consistency and uniformity of the entire building's appearance were ensured.

3. High hardness, wear resistance and scratch resistance.

The main component of the oxide film is aluminum oxide, which makes the surface of the aluminum plate reach gem-level (level 9 hardness) hardness. This hardness not only gives the aluminum plate the characteristics of wear resistance and scratch resistance, but also makes it perform well in places with high flow of people.

Example 1: Shenzhen Metro

As a place with high flow of people, Shenzhen Metro chose aluminum continuous thick film anodized panels as anti-dirty and wear-resistant building materials. Its surface hardness reaches gem level (level 9 hardness), and it can still maintain a stable and beautiful appearance while withstanding high-intensity use.

Example 2: London Heathrow Airport

Aluminum continuous thick film anodized rolls are used in some maintenance access and public areas at Heathrow Airport, the high hardness of which ensures scratch-resistant durability over time.

4. Corrosion-resistant and easy-to-clean environmentally friendly features

The surface oxide film of aluminum continuous thick film anodized coils is inorganic, which makes it environmentally friendly, corrosion-resistant, mildew-resistant, and antibacterial. At the same time, this feature also makes its surface easy to clean, providing convenience for long-term maintenance of the building's appearance.

Example 1: Building facade

Aluminum continuous thick film anodized sheet rolls are particularly suitable for building exterior wall decoration. They can not only resist the erosion of the external environment, but are also easy to clean, improving the convenience of long-term maintenance of the building's appearance.

Example 2: Marina Bay Sands Hotel, Singapore

The exterior wall of the Sands Hotel uses aluminum continuous thick film anodized panels, which are not only corrosion-resistant but also easy to clean, allowing the hotel's appearance to maintain a unique luster.

5. Maintain high-end atmosphere with metallic luster and texture

The surface oxide film is a dense, thin glass-like film that allows the aluminum plate to maintain the luster and texture of the metal. Such design features give the product a high-end and modern atmosphere, and enhance the overall grade and added value of the building.

Example 1: Bank of China Tower, Hong Kong

The Bank of China Building in Hong Kong uses aluminum continuous thick film anodized aluminum panels. Its architectural appearance has clear lines and full texture, showing a high-end and atmospheric modern architectural atmosphere.

Example 2: Shanghai Tower

The aluminum continuous thick-film anodized aluminum coils on the exterior walls of Shanghai Tower give the entire building a modern and high-end metal texture, making it one of the landmarks of Shanghai.

Taken together, aluminum continuous thick film anodized aluminum coils have become an ideal choice in the field of contemporary architecture through their stability, consistency, durability, environmental protection and high-end atmosphere, injecting modern and durable characteristics into buildings.

Informations you may be interested in:

- How to clean anodized aluminum sheet coil roll

- Reasons for irregular oxide film of alloy aluminum coil

- What are the advantages of continuous anodized aluminum sheet coils as building materials?

- What is anodized aluminum sheet coil?

- What skills are needed for hard anodized of 5052 aluminum coils?

- Haomei Aluminum An Overview of the Different Types of Aluminum Coil Stock